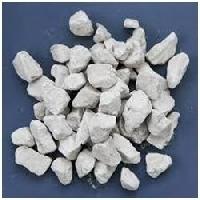

unslaked lime

One of the foremost Suppliers, we are a known for the exceptional unslaked lime in the market. Backed by a capacious warehouse, we can easily undertake urgent and massive orders of the clients. Also, we ensure complete security of the products.

...more

Slaked Lime

With stern quality examinations on varied stages of deigning and manufacturing, even the raw inputs used are completely examined by the professionals. This helps us in delivering the finest array of products with complete precision. Listed amidst the renowned Suppliers of Slaked Lime, we successfully deliver the finest range of products the clients.

...more

Limestone Powder

Limestone Powder that we provide is finely processed with the latest manufacturing technologies at the unit. We provide premium Limestone Powder that is quality-tested, and hence widely in demand. Our Limestone Powder is used in industries to carry out numerous applications. Limestone Powder, offered by us, is available at market leading prices. Chemical Name : calcium carbonate Chemical Formula : CaCO3 Grades Of Limestone Powder Used In Different Industries : Iron & Steel industry : Limestone Lumps are used in this industry both in the blast furnace to lower the temperature of melting and second to from calcium silicate by combining with silica of the iron ore, which comes out as slag. For this purpose, good fluxing Limestone Lumps low in acid constituents such as silica, alumina, sulphur and phosphorus is required. Limestone Lumps should be dense, massive, preferably fine grained, compact and non-fretting on burning. Cement industry : Limestone containing about 45% CaO and above is usually preferred for the manufacturing of cement. Magnesia content in the stone should ideally be less than 3%, although as high as 5% MgO is used by the industry. The proportion of AI2O3 + Fe2O3: SiO2should be 1:2:5. Magnesia sulphur and phosphorus are regarding as most undesirable impurities. Fertilizers industry : The latest use of Limestone Lumps are introduced in the country is in the manufacture of calcium ammonium fertilizers where Limestone Lumps are used only as carrier. For this purpose, Limestone Lumps must contain MgCO3 + CaCO3 85% (min.) SiO2 5% (max.) and acid in-soluble 14% (max.) Glass industry : Glass industry requires Limestone Lumps (CaCO3: 94.5%). Combined CaCO3 and MgCO3 should be 97.5% Chemical industry : The calcium carbide manufactures generally prefer lime containing 95% CaO (min.), not more than 3% SiO2, not exceed 2%. Composition : CaCO3 : 85-97% CaO : 48-more than 54% SiO2 : Below 1% Also Available in Range : Lumps and Chips

Shelf Life : 18 Months

Color : Light-white, White

Form : Powder

Drying Process : Natural

Brightness : Plastic Pouch, Poly Bag, Pp Bags

...more

Limestone Lumps

Also named as Lime stone, natural stone, raw lime stone, Limestone Lumps, offered by us, find their application in diverse industrial segments. We have our own mines of high grade limestone. Mining work to extract premium Limestone Lumps is done on a large scale using latest technology, equipment and under experienced and well-trained engineer�s supervision. Clients can get bulk quantities of Limestone Lumps at reasonable rates from us. Chemical Name : calcium carbonate Chemical Formula : CaCO3 Grades Of Limestone Lumps Used In Different Industries : Cement industry : Limestone containing about 45% CaO and above is usually preferred for the manufacturing of cement Magnesia content in the stone should ideally be less than 3%, although as high as 5% MgO is used by the industry The proportion of AI2O3 + Fe2O3: SiO2 should be 1:2:5. Magnesia sulphur and phosphorus are regarding as most undesirable impurities Iron & Steel industry : Limestone Lumps are used in this industry both in the blast furnace to lower the temperature of melting and second to from calcium silicate by combining with silica of the iron ore, which comes out as slag. For this purpose, good fluxing Limestone Lumps low in acid constituents such as silica, alumina, sulphur and phosphorus is required. Limestone Lumps should be dense, massive, preferably fine grained, compact and non-fretting on burning. Chemical industry : The calcium carbide manufactures generally prefer lime containing 95% CaO (min.), not more than 3% SiO2, not exceed 2% Glass industry : Glass industry requires Limestone Lumps (CaCO3: 94.5%). Combined CaCO3 and MgCO3 should be 97.5% Fertilizers industry : The latest use of Limestone Lumps are introduced in the country is in the manufacture of calcium ammonium fertilizers where Limestone Lumps are used only as carrier. For this purpose, Limestone Lumps must contain MgCO3 + CaCO3 85% (min.) SiO2 5% (max.) and acid in-soluble 14% (max.) Composition : CaCO3 : 85 % -97% CaO : 48% - more than 54% SiO2 : Below 1% Also Available in Range : Powder and Chips

Color : Available in many colors

Application : Industrial

...more

Limestone

16 Metric Ton (MOQ)

We are offering limestone. lime stone are raw stones containing principal element as calcium carbonate. Company is mine owner of high grade lime stone. Mining work on large scale is done using latest technology, equipments and under experienced and well trained engineer’s supervision.

...more

Hydrated Limestone Powder

Hydrated limestone powder that we provide is also commonly used in india as salked lime, lime powder and calcium hydroxide. Hydrated limestone powder is a dry powder manufactured by treating quicklime with sufficient water to satisfy its chemical affinity for water, thereby, converting the oxides to hydroxides. Depending upon the type of quicklime used and the hydrating conditions employed, the amount of water in chemical combination varies, as follows: high calcium hydrated lime-high calcium quicklime produces a hydrated lime containing generally 72 % to 74 % calcium oxide and 23 % to 24 % chemically combined water. high purity hydrated limestone powder reduces handling cost and transportation and also increases quality of finish product. On specific demand we can provide hydrated limestone powder with ca(oh)2 more than 90% that is up to 94%. chemical name : calcium hydroxide chemical formula : ca(oh)2 major applications areas : water treatment planteffluent treatment plantpaint industrypetroleum refining industryfood industryleather industrypaper industrymetallurgical industry (copper, aluminum, steel, iron, etc.)glass industrypharmaceutical industrydi calcium phosphate manufacturingrubber industryroad making and construction industrysugar industry applications : ph controlpesticidesfertilizersmarblegranite cuttingcement paintsbleaching powder details : packing : 50 kg bags1000 kg bagsavailable mesh size : 200300.

...more

Dolo Lime

We have well-connected and capacious warehouse that helps us in arranging products systematically to deal with urgent deliveries and orders. Our exceptionally good warehouse system helps us in keeping the products safe till the final dispatch. In order to settle the financial transaction with our clients through the transfer of monetary value, we offer diverse options including online and offline payment procedures.

...more

Calcined Lime

16 Metric Ton (MOQ)

We are offering calcined lime. calcined lime (quicklime or calcium oxide, or burnt lime, or un-slaked lime), is obtained by calcination of (controlled heating - time and temperature) limestone at temperatures above 900°c. This highly reactive product is essential to many industrial processes. Constant quality is achieved on grounds of self owned lime stone mines, complete own infrastructure for calcinations and quality management etc.

...more

Calcined Dolomite Lumps

Our Calcined Dolomite Lumps are commonly named as: Burnt Dolomite, DoloLime, Calcined Dolomitic lime, steel grade dololime and steel grade dolomite. The Calcined Dolomite Lumps are a result of Calcinations of Natural Dolomite Lumps. After burning, calcium oxide contains becomes 50% to 55% and Magnesium Contains 30% to 38%. Therefore, we have given it name of Dolo Lime, Calcined Dolomite or Burnt Dolomite. Calcined Dolomite Lumps have normally been formed by the replacement of some of the calcium in limestone with magnesia, a process known as dolomitisation. Theoretically, dolomitic lime should be a stoichiometric mixture of CaO and MgO, i.e. 58% CaO and 42% MgO. In practice, because of impurities and differing levels of dolomitisation, commercial products normally contain 35-40 % MgO. Calcined Dolomite Lumps are the best catalysts and base chemical for steel plants. Chemical Name : Calcium Magnesium Oxide Chemical Formula : MgO.CaO Major Applications : Iron and steel industry Non-ferrous metals Ore concentration Alumina and bauxite Gas treatment Hazardous waste treatment Animal waste treatment Details : Packing : 50 kg bags/1000 kgs bags Available Mesh Size : 200/300 and Lumps

Color : White

Packaging Type : Gunny Bag, Jute Bag, Plastic Packet

Feature : Durable, Freshness Preservation, Good Strength, Hard Structure, Heat Resistance, Lite Weight, Long Life

Packaging Size : 100gm, 1kg, 250gm, 50kg

...more

Calcined Dolomite

500 Metric Ton (MOQ)

We are offering calcined dolomite. the calcined dolomite (burnt dolomite or dolo lime) is a result of calcinations of natural dolomite lumps which contains 50% to 55% caco3 and 37% to 40% mgco3. After burning, calcium oxide contains becomes 50% to 55% and magnesium contains 30% to 38%. We have given it name of dolo lime, calcined dolomite or burnt dolomite

...more

Hydrated Lime

We are offering hydrated lime. hydrated lime (slaked lime) is a dry powder manufactured by treating quicklime with sufficient water to satisfy its chemical affinity for water, thereby converting the oxides to hydroxides. Depending upon the type of quicklime used and the hydrating conditions employed, the amount of water in chemical combination varies

...more

chemical lime

Dolomite

Lime Stone

sinter grade lime

Transportation Services

Transportation of lime products through out india at cheapest freight rate.

...moreOpening Hours