Transit Mixer

900,000 Per Piece

Silo Top Filter

The Silo Top Filters are produced using stainless steel in order to provide required ventilation to the silos. A dust collector is placed in the filters to ensure that none of the dust particles escape into the silos. These equipments have high efficiency in filtrating the emitted dust particles. Hence, these are safer choices to make an investment. The maintaince of the Silo Top Filter is minimal since a weather protection cover is situated inside the cleaning unit. Safe weather protection cover with lockable snap hook, No tools required for filtering element removal, Perfectly accessible due to compact design, Complete replacement of filter media by only one person within a few minutes.

...more

Screw Conveyor

50,000 Per Piece

Feature : High quality seamless precision, oil leakages and durable.

Brand Name : Powerol

Material : Steel

...more

Ready Mixed Concrete Mixing Plant

1,500,000 Per Piece

1 Piece (MOQ)

Brand Name : Powerol

Voltage : 220 V

Pressure Release Valve

The cement silos form enormous pressure while it discharges the cement. The Pressure Release Valves performs the function of controlling the high pressure in order to ensure that the silos are unaffected by the pressure development. The valves start functioning only when the pressure reaches the pre-set pressure limit value. The valves effectively control the pressure in the silo and keeps it stable at the obligatory level. Not just that, it ensures that none of the cement silo filters breaks off abruptly from the silo. The primary function of the valve is to control the pressure released while transferring the silobus into the cement silo. During the transfer of the silobus, high pressure accumulates in the silo. Even if there is no silobus to onpass, the air that the silobus holds inside is transferred into the silo. If the valves fail to function properly, the filter of the cement silo can be extensively disrupted.

...more

Pneumatic Feeding Pump

These machineries use simplified technology to transfer the cement from single collection point to single/multiple reception points. Huge quantity of cements are disposed of in the pipes at comparatively lower velocities. Use of compressed air makes the device cost-effective and easier to use. These machines can withstand a temperature upto 450 degree centigrade and can cover distances of 200 meter. One can choose the perfect machinery in accordance with the distance and quantity that needs to be covered in their own Industrial purpose.

...more

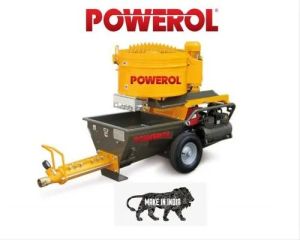

Plastering Machine

450,000 Per Piece

01 Piece (MOQ)

Country of Origin : Made in India

Voltage : 230V

Minimum Maximum level indicator

Minimum – Maximum level indicator is widely used to keep a check on the volume of cement that is filled in the silo. Rotating motion allows easy handling of this machine that helps to conclude the maximum and minimum level of cement in the silo.When the amount of cement reaches the turning pedal of the indicator, it conveys that the desired amount has been reached. The drop in the cement quantity is indicated when the turning pedal changes the course of action again causing the other parts to move as well. These machines can usually determine the filling level of materials that has a density between 0.5-2.0 ton/m³. These machines are usually located in the top-end and lower-end of the cement silo.

...more

concrete trailer pump

1,500,000 Per Piece

Power : Diesel & Electric

concrete recycling plant

1,500,000 Per Piece

Voltage : 440v

Type : Concrete Recycling Plant

Concrete Bucket

35,000 Per Piece

Material : Mild Steel

Concrete Batching Plant

150,000 Per Set

Frequency : 50 Hz

Material : Mild Steel

Voltage : 220 V

...more

cement silos

350,000 Per Piece

01 Piece (MOQ)

Material : Mild Steel

Capacity : 30mt to 500mt

Country of Origin : Made in India

...more

Cement Flyash And Microsilica Silo

Recently, Powerol has started a separate factory outlet for the production of Cement /Flyash /Microsilica Silo with silo capacity ranges from 20MT to 500MT. Powerol’s efficiency in producing quality products have dramatically increased the commercial value of these products. Silos can contain varying capacities of powder materials and are processed using drilling techniques and cnc cutting technology. The use of Silos mainly lies in holding and discharging construction materials such as Cement or Flyash. Some Silos can hold comparatively lower measurements and therefore, can be taken from place to place for their capacity to move.The silos which contain cement are usually layered with prime coating and final coating. The part of the silo that hangs on the automatic conveyor line is usually painted in specially made painting cabinets. Only after all this procedure can a silo be packed for transportation to the destined construction site. Cement silos have huge leg-stands to hold the weight of the heavy loads. Ladders and upper parapets are used to reach the topmost sections.A silo has a valve in the discharging section that can be controlled manually. The pipe that fills the silo with cement is constructed in the outer section. The transportation cost of these silos are very affordable.

...more

Butterfly Valve

A shutting-off valve that is simplified in its construction and use is known as a Butterfly Valve. This valve regulates or prevents the flow of water supply, waste water, oil or fuel in a variety of Industrial usage. The disc blocs in the valve can be opened or closed according to the Industrial need. The simple construction, lighter weight and affordable price of butterfly valves makes these an immensely popular choice.

...more

Bucket Elevator

Capacity : 4-5 ton

Material : Mild Steel

Aggregate Feeding Belt Conveyors

850,000 Per Piece

Brand Name : Powerol

Aeration Nozzle

The fluidizing system in silo requires distribution pipes and nozzles. These nozzles are mainly used in Industries that require pollution control such as Construction Sites and Water Treatment Sectors. Powerol has highly efficient team of professionals who are able to guide the customers regarding the nozzles that would work best for their business needs. The system in aeration nozzles are advantageous since it causes least possible damage to the interior wall of the cement silo like the vibrators do. Hence, aeration nozzles are technically a better choice to invest in.

...moreBe first to Rate

Rate ThisOpening Hours