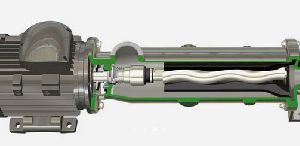

Wide Throat Pump

1 Set(s) (MOQ)

Features : \n \n Steady, low-pulsation pumping \n High self-priming rate \n Installation possibilities in all positions \n Direction of rotation and thus delivery flow reversible \n Non-clogging: handles solids in suspension or mixture containing high percentage of solids. \n Can work on Snore: inherently self-priming. \n High Suction Lift: low NPSH(R), effective in high vacuum conditions. \n Minimal Internal Wear: Gentle handling of shear sensitive and abrasive products because of low internal velocity. \n Reversible: suction and delivery ends can be interchanged by merely changing direction of rotation of the prime mover. \n \n Material Options :WETTABLE HOUSING COMPONENTS :• Fabricated Stainless Steel.STATOR :• Nitrile Black • Nitrile White • EPDM Black • EPDM White • Fluoroelastomer.ROTOR :• Stainless Steel.COUPLING ROD :• Stainless Steel.SHAFT :• Stainless Steel.OTHER EXOTIC MATERIALS :Duplex • Super Duplex • Alloy 20 • Haste alloy.

Type : Horizontal /diagonal Progressing Cavity Single Screw Pump

Power : Electric / Mechanical

Pressure : Up To 24 Bar

...more

Vertical Progressive Cavity Pump

1 Set(s) (MOQ)

Material Options :WETTABLE HOUSING COMPONENTS :• Fabricated Steel • Fabricated Stainless Steel.STATOR :• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBRROTOR :• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless SteelCOUPLING ROD :• Alloy Steel • Stainless SteelSHAFT :• Alloy Steel • Stainless SteelOTHER EXOTIC MATERIALS :• Duplex • Super Duplex • Alloy 20 • Haste alloyROTOR SURFACE COATINGS :• Ceramic Coatings • Tungsten Carbide • Hard Chrome PlatingPROTECTIVE COATINGS :• Rubber Lining • Epoxy Coatings

Type : Virtical Progressing Cavity Single Screw Pump

Power : Electric / Mechanical

Pressure : Up To 24 Bar

...more

Stator Spare Parts

Type : Bonded MS.Sleeve & S.S.Sleeve/ Free Fitting

Rotor Spare Parts

2 Piece(s) (MOQ)

Metering Pump

Features : \n \n Inherent Self-Priming Capability \n Non-clogging \n Low NPSH (R) \n Non-pulsating and smooth flow \n Low Operating costs \n High suction lift capability of up to 9.0 MWC \n Gentle Handling of shear sensitive & abrasive media due to low internal velocity \n \n Material Options :WETTABLE HOUSING COMPONENTS::• Cast Stainless SteelSTATOR :• Natural, • Nitrile, • High Nitrile, • EPDM, • Hypalon, .ROTOR :• Stainless Steel.COUPLING ROD :• Stainless Steel.SHAFT :• Stainless Steel.OTHER EXOTIC MATERIALS :Duplex • Super Duplex • Alloy 20 • Haste alloy.OTHER EXOTIC MATERIALS :• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

Type : Horizontal / Virtical Progressing Cavity Single Screw Pump

Power : Electric

Pressure : Up To 6 Bar

...more

Joint Spare Parts

2 Set(s) (MOQ)

Material : AISI316/AISI304/AISI410/TOOL STEEL/ALLOY STEEL/ GUNMETAL

Type : Universal/open Joit/head Joint/threded Joint/pin Bush Joint

Size : Standard

Surface Finishing : Polished

...more

Hygienic Food Grade Pump

1 Set(s) (MOQ)

Features : \n \n Contact parts in smooth finish stainless steel \n Stators are made of non-contaminating food grade polymers, resistant to oils, fats etc \n All internal contours are designed to be swept by the product flow or by a detergent when “in-line” cleaning \n Elimination of product retaining pockets avoids chemical or bacteriological contamination \n Simple construction allows quick dismantling along with easy mounting joints ensures service friendliness. \n CIP (Cleaning in place) design allows for residual-free and bacteria-free cleaning. \n SIP (Sterilization in place) can be done using Superheated steam for in-process equipment \n Can work against high vacuum. Ideal for lifting viscous fluids from the vacuum pan. \n Low fluid velocities ensures gentle handling of shear sensitive fluids without damage \n \n Material Options :WETTABLE HOUSING COMPONENTS :• Fabricated Stainless Steel.STATOR :• Nitrile Black • Nitrile White • EPDM Black • EPDM White • Fluoroelastomer.ROTOR :• Stainless Steel.COUPLING ROD :• Stainless Steel.SHAFT :• Stainless Steel.OTHER EXOTIC MATERIALS :Duplex • Super Duplex • Alloy 20 • Haste alloy.

Type : Horizontal / Virtical Progressing Cavity Single Screw Pump

Power : Electric / Mechanical

Pressure : Up To 24 Bar

...more

Dosing Wobble Pump

Features : \n \n Flow is directly proportional to the speed \n Suction lift capacity up to 8m \n Minimal pulsation avoids damage to shear sensitive products \n Can handle liquids with fine solids \n Minimum impacts with efficiencies with varying heads \n Simple in design and easy to dismantle \n Low maintenance cost \n \n Material Options :WETTABLE HOUSING COMPONENTS::• UV Resistant acetant co-polymer housing for pump sizes DC 11 & DC 31• C.I. Housing parts for pump sizes DC 41 & DC 51.STATOR :• Natural, • Nitrile, • High Nitrile, • Fluoroelastomer.ROTOR :• Stainless Steel.ROTOR SURFACE COATINGS :• Hard Chrome Plating.SHAFT :• Stainless Steel.

Type : Horizontal Progressing Cavity Single Screw Pump

Power : Electric

Pressure : Up To 6 Kg

...more

Chemical Progressive Cavity Pump

1 Set(s) (MOQ)

Features : \n \n Steady, low-pulsation pumping \n High self-priming rate, \n Installation possibilities in all positions \n Direction of rotation and thus delivery flow reversible \n Non-clogging: handles solids in suspension or mixture containing high percentage of solids. \n Can work on Snore: inherently self-priming. \n High Suction Lift: low NPSH(R), effective in high vacuum conditions. \n Minimal Internal Wear: Gentle handling of shear sensitive and abrasive products because of low internal velocity. \n Reversible: suction and delivery ends can be interchanged by merely changing direction of rotation of the prime mover. \n Versatility: handles abrasive, shear sensitive and viscous materials, solids in suspension and air-solid-liquid mixture. \n \n Material Options :WETTABLE HOUSING COMPONENTS :• Cast Iron • Cast Steel • Stainless Steel 304/316 • Duplex SS • Monel Alloy • Haste alloy B/CSTATOR POLYMERS :• Natural • Nitrile, • High Nitrile, • EPDM, • Chloro-Sulphonated Rubber(Hypalon), • Fluoroelastomer • Sillicone • HNBRROTOR :• Tool Steel • Case Hardened Steel, • Alloy Steel • Stainless Steel 410/304/316/316L.OTHER ROTATING ELEMENTS :• Alloy Steel • Stainless SteelEXOTIC MATERIALS AVAILABLE FOR SPECIAL APPLICATIONS :• Duplex Steel, • Super Duplex • Monel • Haste alloy B/CROTOR COATING FOR SPECIAL APPLICATIONS :• Ceramic Coatings • Hard Chrome Plating

Type : Horizontal Progressing Cavity Single Screw Pump

Power : Electric / Mechanical

Pressure : Up To 24 Bar

...more

Barrel Empty Pump

1 Set(s) (MOQ)

Features : \n \n Works on the unique progressive cavity principle \n Simple in design and easy to use \n Suitable for viscous media applications with high suction lifts \n Torsion-free metal-bonded stator for increased stator life and higher efficiency \n Simple and robust design to minimize wear of internal parts \n \n Material Options :WETTABLE HOUSING COMPONENTS :• Fabricated Steel • Fabricated Stainless Steel.STATOR POLYMERS :• Natural • Nitrile, • High • Nitrile,• EPDM, • Silicone HNBRROTOR :•Tool Steel • Case Hardened Steel, • Alloy Steel • Stainless Steel 410/304/316/316L.OTHER ROTATING ELEMENTS :• Alloy Steel • Stainless SteelEXOTIC MATERIALS AVAILABLE FOR SPECIAL APPLICATIONS :• Duplex Steel • Super Duplex • Haste alloy B/CROTOR COATING FOR SPECIAL APPLICATIONS :• Ceramic Coatings * • Hard Chrome Plating

Type : Virtical Progressing Cavity Single Screw Pump

Pressure : Up To 12 Bar

Power : Electric

...more

pumps Making Service

pumps Making Service

pump repairing services

Pump Repairing Services

Opening Hours

Deepa Engineering Works is an esteemed organization from Kanpur (Uttar Pradesh) that excels in the production and trade of industrial pumps and spare parts. The company is known as a successful manufacturer, exporter, and supplier of superior quality industrial pumps (chemical progressive cavity pump, hygienic food grade pump, vertical progressive cavity pump, barrel empty pump, wide throat pump, metering pump, dosing wobble pump) and spare parts (stator spare parts, joint spare parts, & rotor spare parts). We use high quality materials and components in the process to let users enjoy trouble-free operation of pumps and hassle-free installation of spare parts. We also use 100% cotton and canvas fabrics to produce good quality products. Our products are duly certified from the quality standardizing body, and we offer only QC okayed products in the market. Our products are highly admired and appreciated across the domestic and international markets.

Deepa Engineering Works was established in the year 2002 with a vision of serving clients with the best industrial pumps and spare parts, which comply with the laid quality standards and guidelines. We have been growing by leaps and bound under the astute leadership of Mr. Inderpal (Co. Founder), who is a veteran in the domain of manufacturing.

Quality Control

A team of proficient quality controllers keeps an eye over the raw material as well as finished goods’ quality so that even the minor imperfections could be removed prior to the final delivery. We also use advanced equipment in our quality control process so that no defective products could reach the buyers.