Wet Mixer

We are main supplier of this product.

Wet Grinder

Economic Products Introducing Wet & Dry Grinder. The Description of Wet & Dry grinder Machine Non Jacketed which is as Follows. Grinding of the material by hammering & material will discharge from the screen as per customer's requirement. It is based on heavy duty Angle / Channel Frame, heavy duty main shaft with bearing housing as per our std. fifty. It is available in 8 modles. The Description Of Wet & Dry Grinder Machine Non Jacketed Which Is As Follows: Ideal For Following Materials Rice Coconut Coriander Leaves Udad Dal Sugar Ground Nut Moong Dal Ginger-Garlic

...more

Vibrating Sieve

Shri Krishnaji Vibrating Sieve is the most Efficient Vibrating Screen or Vibrating Sieve for Dry Screening. Vibrating Screen is compiled of mainframe, eccentric bock, screen web, rub spring, electric motor, coupler and some more. Very much suitable for chemical and Pharmaceutical Industries. Depends on physical properties and particle size of the material. Application Ceramic Industry, Detergent Powder, Chemical Additives, Spices, Abrasives Ceramic Slip, Polymer Resin/Plastic, Preparation Plant Biscuit Glazed Section, Effluent, Pallets/Power, Paint Pharmaceuticals, Sodium Sulphate, Calcinede Foods Industry, a. Fiber Recovery, Refractory, Tea, Petroleum Coke, Chemicals & Pharmaceuticals, Gelatin Sand & Glass, Cattle Feed, Cellulose Powder, Metal Powder/Shot & Grits, Table Salt. How It works ? The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly, Rotation of the top eccentric weights creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery increasing the top eccentric mass. The bottom eccentric weight rotates below the centre of vibrating, mass creating till on the screen giving vibration in vertical & tangential planes increasing the vertical component of motion which promotes turn over of material on the screen surface helping maximum quantity of undersize material to pass through the screen. The effective vertical motion helps in minimizing blinding of screen by ‘near size' particles. The tangential component of motion is controlled by the angle of lead given to bottom weight with relation to top weight. Features Simple and dependable Eccentric type system. High screening capacity. High durability. No transmission of screen panels. Ready changing of screen plates. Rigid and vibrating resistance screen body.

...more

Vertical Bucket Elevators Centrifugal / positive Discharge

These are similar to the centrifugal discharge type, except that buckets are snubbed back under head sprockets to gain a more complete discharge at a slower chain speed. The elevators can handle light aerates, dusty and sticky materials that are not easily dischargeable from a centrifugal discharge elevator. The buckets are mounted at intervals on two strands of chain. Providing a capacity equal to the centrifugal discharge type requires larger buckets or closer spacing of buckets on the chain. This is a forced type of discharge and is thus effective in transferring maximum of the carried material over to the destination. Note: (1) It is available in various models depending upon production capacity & H. P. required.(2) Machine/Material can be changed as per customer's requirement.

...more

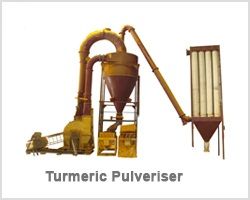

Turmeric pulveriser

For Turmeric, amchoor, & pepper- our pulveriser gives the best result in single time grinding. Fully cast iron body ensures lower temperature grinding for spices and production ranges from 15 kgs to 1500 kgs per hour of all powder.

...more

Turbo-Gyro Pulveriser

Our new invention in the form of Turbo Gyro Pulveriser ensures very high mesh powder grinding to mesh like 500 to 1500 mesh. One great feature includes regulatory mechanism- which ensures control of mesh of powder without opening any unit/ pulveriser. Its a modern era unit to suit mineral & chemical or any fine grinding industry.

...more

Tray Dryer

A tray or Compartment Dryer is an enclosed insulated chamber in which trays are placed on top of each other in trolleys. The material to be dried either wet or solids are placed in the tray. Heat transfer is done by circulation of hot air by electric heaters in radiator coils. Blower fans are installed inside to ensure proper circulation and transfer of heat. A control panel to control the temperature and other parameters is fixed outside the dryer. There is also arrangement of digital temperature controller. These dryers available in mild Steel, Stainless Steel or Al construction. Used for drying Pigments food Bakery Electrodes Chemical Plastic Powders

...more

Tablet Punching Machine

shri krishnaji tablet punching machine has following salient features gravity feeding system two piece turret upper roller with penetration adjustment system control panel with bypass switches control panel with separated display for tablet count and rpm fixed hopper with slide to control powder flow hand wheel provided re-designed variable speed pulley cam tracks and pressure rollers made out of alloy steel for maximum wear resistance and long life. Worm is made up of phosphor bronze machine is totally enclosed i.e. Top half of the machine (compression zone) with ss hood, acrylic covers in skp model. This reduce the noise level and to and fro flow of dust between compression zone and machine room. higher speed 15 to 35 rpm phosphorus bronze bush provided inside the turret hole ss guards lower punch cam can be removed without dismanting the lower roller assembly. optional features double layer attachment electro nickel including nickel die plate lower punch key way for break-line/ embossing alignment

...more

Sulpher Grinding

Sulphur Grinding Machinery- Sulphur being a typical chemical tbo grind & being explosive in nature, we recommend our 3 Roller Mill for grinding at low rpm to ensure better grinding & safety.

...more

Sugar Powder

Coase Sugar Powder For general purpose biscuit & dairy whitener purpose sugar- our Pin Mill is used. We are renowned globally as a leading pulverisers manufacturing company. We manufacture pulverising & grinding equipments for over 3 decades.

...more

Industrial Stirrer

Portable stand Shri Krishnaji Stirrers are versatile mixers used for mixing of liquid at slow speed. Any one fixed speed is provided. The units are available with various different types of impellers

...more

Screw Conveyors

These types of conveyors are basically for bulk materials with variable properties depending on the application. They can be sealed against dust or moisture, jacketed to act as dryer or cooler. Screw flights fabricated in an array of configurations perform different tasks or help to convey different types of materials. Ribbon flights density and viscous materials which may usually cause bridging at the centre tube. Screw conveyors are compact and easily adapted to suit any location. They can be manufactured in any type of orientation and direction either horizontally, inclined or vertical. These types of conveyors can be used to feed, distribute, collect or blend materials flow in processing or conveying operation. [1] Screw feeder / dozer [2] U- Trough / Tubular Screw[3] Inclined Screw [4] Bi-direction Screw The materials of construction may be mild steel or stainless steel depending on the requirement. Special materials like polymers have also proved to be an excellent alternative to steel.

...more

Screw Conveyor

These types of conveyors are basically for bulk materials with variable properties depending on the application. They can be sealed against dust or moisture, jacketed to act as dryer or cooler. Screw flights fabricated in an array of configurations perform different tasks or help to convey different types of materials. Ribbon flights density and viscous materials which may usually cause bridging at the centre tube. Screw conveyors are compact and easily adapted to suit any location. They can be manufactured in any type of orientation and direction either horizontally, inclined or vertical. These types of conveyors can be used to feed, distribute, collect or blend materials flow in processing or conveying operation. [1] Screw feeder dozer [2] U- Trough Tubular Screw [3] Inclined Screw [4] Bi-direction Screw

...more

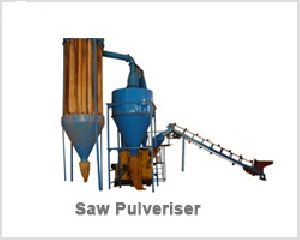

saw dust pulveriser

Our pulveriser is best suited for pulverizing of Brown Saw Dust mainly used for mosquito coil purpose. Our numerous machines on this application is being used at Pondicherry, Jammu, Guwahati, Assam, Meghalaya, Myanmar, etc. (Picture attached by name of Saw Dust Pulveriser - please clear the background)

...more

Rotatory Air Lock Valve

Our team makes every effort to present a qualitative and certified array of products. As a respected name in the industry, we make use of only high-grade packaging material for the safe packing of the products. Thus, we ensure zero damage at buyer's end.

...more

Rotary Valve (Air Lock Valve)

Shri Krishnaji Rotary Air Lock Valve is designed to efficiently transfer non-stringy materials from one air system component to another, ensuring maintenance of a required vacuum or to prevent pressurization. The air lock maintains a tight, positive air seal by keeping a maximum of the six flexible neoprene steel backed wipers in full contact with the interior housing at all times. The neoprene wipers are bolted to the vanes of the rotor tips for easy of maintenance. The rotors are open-ended. The rotor housing is heavy-duty steel construction with a removable side plate to provide easy access and maintenance of the rotor.

...more

Rolling Machine

Roll Cutting Machine

We are main supplier of this product.

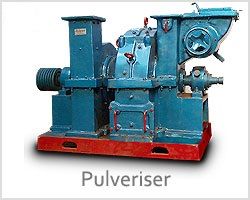

PULVERIZER

Shri Krishnaji Industries is an ideal unit for grinding non-abrasive soft medium and hard minerals and also Gram-dal tamarind seed. The pulveriser is manufactured from best raw materials. The main body of the grinding chamber whizzer chamber and the blower are made of heavy duty cast iron every portion which comes in contact with the materials is lined with heavy duty steel plates. The striking face of the grinding chamber is lined with hard iron replaceable plates. Thus protecting the machine from wear and ensuring it for long life. The grinding chamber is provided with a pocket in which small pieces of iron nuts and bolts are trapped. The main drive shaft is run on two double row self aligning heavy duty Ball or Roller Bearings.

...more

Pulverizers

Shri Krishnaji Industries is a high swing type grinding mill pulverisation is achieved by the impact of the grinding chamber. The fine Powder is swept by the blower suction from the grinding chamber via whizzer cone. The function of whizzer cone is to check the oversize particles and thus to regulate fineness SAND IS SEPARATED OUT from material from the grinding chamber by a special arrangement at an extra cost. The blower delivers the pulverised powder in the cyclone air separator. The powder is discharged from the cyclone spout. The separated air return to the grinding chamber to complete the air circle. The excess air is bled off through dust collector filter bags. The extra fines are collected there. Shri Krishnaji Industries is an ideal unit for grinding non-abrasive soft medium and hard minerals and also Gram-dal tamarind seed. The pulveriser is manufactured from best raw materials. The main body of the grinding chamber whizzer chamber and the blower are made of heavy duty cast iron every portion which comes in contact with the materials is lined with heavy duty steel plates. The striking face of the grinding chamber is lined with hard iron replaceable plates. Thus protecting the machine from wear and ensuring it for long life. The grinding chamber is provided with a pocket in which small pieces of iron nuts and bolts are trapped. The main drive shaft is run on two double row self aligning heavy duty Ball or Roller Bearings. Spare Parts: All the Spare Parts are standard and available Note: (1) It is available in various models depending upon production capacity & H. P. required.(2) Machine/Material can be changed as per customer's requirement.

...more

Pin Mill

shri krishnaji pin mill is specially designed to deal efficiently and economically with a wide range of materials and can be easily adjusted to give the fineness required from a coarse granulation to finely ground powder. pin mill grinding is gradually done from the centre to the periphery of the rotor, allowing heavy pieces of material to be reduced by stages to the fineness required. Constructional materials and operating components are manufactured out of the best applicable raw materials, so as to yield close particle size for a similar product. pin mill yields greater output in relation to the electrical energy consumed, since the material can be ground is fed automatically in the centre of the rotor by the feed hooper provided with an automatic vibrating tray / rotor feeder & gear box for automatic feed. pin mill is subjected to rigid final inspection and actual grinding tests at our experimental station before it is delivered to the stores for dispatch. Grinding tests with your materials can also be carried out without obligation, to testing the suitability of the pin mill for your satisfaction. industries pin mill is used in (1) dye stuff pigment and color (2) chemical (3) food stuff(4) spice (5) bakery(6) confectionary (7) agro (8) salt (9) ayurveda (10) pharmaceutical (11) dehydrated fruit fit and vegetable (12) tea (13) cosmetic (14) glass (15) plastic (16) bakelite fit resin (17) mineral (18) ceramic (19) rare earth metallic ore (20) explosive item (21) cattle feed (22)tobacco-snuff (23) wood chips (24) coke and other many applications [1] permissible feed size up to 6.00 mm [2] fineness achievable up to 40 mesh [3] permissible hardness up to 3 moh's scale [4] permissible brittleness medium to high [5] permissible moisture up to 3% standard supply pin mill fitted with feed hooper, set of fixed beater plate, set of rotor plate, screen drum with screen, & ‘v’ pulley for machine.

...more

mineral grinding machine

Our variety of machines aim to provide the best solution for different minerals- Pulveriser- For high production, high mesh 100- 350 mesh of mineral powder. 3 Roller Mill- For high production, high mesh 100- 350 mesh of mineral powder, with an advantage of low electrical consumption. Double Drive Pulveriser- For higher mesh like 300- 400 mesh production of minerals. Turbo Gyro Pulveriser- For very very high mesh like 400- 1500 mesh production on minerals.

...more

Micro Wave Dryer

Shri Krishnaji High Frequency Dryerwelcomes you to the intriguing world of High Frequency (HF) and Microwave dielectric heating. The technology of heating specific materials, based on the relationship and interaction of electromagnetic energy and the dielectric properties of the materials, is extraordinarily complex. At the molecular and atomic levels there are four different types of polarization that can be involved in the heating of a dielectric, depending on the dielectric material and the frequency of the electromagnetic field. These are electronic and atomic polarization, where the dipole moments are induced by the displacement of electrons and nuclei, respectively, Orientation caused by the rotation of permanent dipole moments. Interfacial polarization, a space charge, that is the result of a build up of migrating charge carriers, The heat developed in a dielectric by an alternating electromagnet (EM) field, is always, a result of one or more of these types of polarization being initialized. The types of polarization initialized are frequency and material dependent. SHRI KRISHNAJI has furnished Radio Frequency dielectric heating equipment to various industries, These include wood products, ceramics, textiles, foods, foundries and plastics. This multi-industry experience allows us to transfer technology to benefit all, Each project is a challenge to find the most cost effective, efficient and practical solution tailored to your specific situation. SKP has the experience, the staff and the technology to help solve your process heating problems.

...more

Jaw crusher

“Shri Krishnaji Jaw Crusher” is the product of long experience and skilled workmanship. The crusher is available mild steel body. The crushing is achieved between the fixed jaw held in the body and the swing jaw held in the jaw stock. The main driving shaft, which is eccentric gives elliptical to and fro motion to the jaw stock. The discharge opening is adjustable hence the size of the end product can be controlled by the control lever. The two heavy cast iron flywheels are provided to ensure steady running. Drive arranged either direct through the flywheels or through a suitable pulley. Shri Krishnaji Industries Jaw Crusher Features: (A) Jaw Stock made of heavy duty cast iron/mild steel with provision to held the swing – jaw. (B) Swing Jaw are made of manganese alloy iron or steel and are replaceable can be used both ends. (C) Fixed Jaw are made of manganese alloy or steel and are replaceable. They can be used both ends. (D) Check Plates have two fold purposes. First it holds the fixed jaw with the body and secondly it protects the sides of the body from the wear. (E) Tie Rod made of steel. Meant for hold the jaw stock. (F) Toggle Plate is made of cost iron. It impart the rolling motion to the jaw stock. (G) Fly Wheels: made of heavy duty cast iron for ensuring the smooth running and providing reserved power to jaw. (H) Bearing: All bearing are heavy duty ball Bearing and Roller Bearing. (I) Control Lever: To adjust the discharge opening of the crusher. >> More details on Jaw Crusher

...moreBe first to Rate

Rate This