Chilli Grinding Machine

Get Price Quote

The Chilli Grinding Machine is suitable for grinding chili, coriander, and mix masala. Quick suction and casted internals of Chilli Grinding Machine ensure output of low temperature masala powder. Chilli Grinding Machine can be availed from us in 2 varieties- single machine double grinding and online system. Production Range : 10 kgs to 1000 kgs per hour

Impact Pulveriser

Get Price Quote

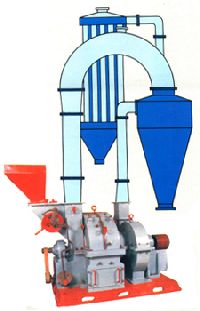

we are one of the preeminent manufacturers and exporters of impact pulverizers in the market. We are offering a wide range of impact pulverizer that can be used in various processing field. These are designed and developed in diverse sizes to ensure excellent crushing efficiency in diverse applications. Our range of hammer mill and impact pulverizer can be customized as per the specific requirement of our clients. properties low specific power consumption automatic feeding durable long life guaranteed grinding efficiency best capacity utilization minimum intermittent handling low maintenance\ applications food industry chemical and mineral industries paint and pigment industry mineral & ore industry coal processing industry spice industry sawdust and coconut shell industry tamrind seed industry pharmaceutical industry specifications swing hammer type grinding chamber lined with replaceable lining plates built-in whizer classifier strong suction blower all the wearing parts of the grinding chamber whizer classifier and the blower are lined with replaceable lining plates the main driving shaft (en-8) runs on a pair of heavy duty self aligning ball/roller bearing fitted in dust proof bearing housing the hammers are forged steel coated with very hard alloy cyclone air separator complete with connecting pipes and angle iron frame for cyclone a automatic feeder is provided for regular feed and static type dust collector with angle iron frame but without electric motor

Best Deals from Spices Processing Machinery

Double Drive Pulverizer

290,000 - 1,700,000 Per Piece

1 Piece (MOQ)

Introduction Shri Krishna Double Drive Pulverizer is a high speed swing hammer type grinding chamber lined with suitable lining plates. The machine works on the principle of grinding. The unit is driven by separate motor and Centrifugal Blower. Working The raw materials to be pulverized are entered in the grinding chamber through the feeding hopper and automatic rotary feeder. The grinding chamber comprises of swing-type hammers. This unit produces super fine final product by the impact of hammers on the feeded raw material against the lining plates with a greater force as compared to the impact pulverizer machine. The separately driven Centrifugal Blower sucks the super fine product from the grinding chamber via the Double Whizzer Clamp. Whizzer Classifier is responsible for fine regulation i.e. to check for over-sized particles and thereby allowing only the super fine powder to go through. The over-sized particles are sent back to the grinding chamber for re-grinding. The powdered material sucked by the Centrifugal Blower is finally thrown to the cyclone air separator. The final product is discharged from the cyclone spout for collection and bagging. The required air for the grinding process is sent back to the grinding chamber and excess air is rejected out through the tubular dust collector filter bags. The dust collector bags also hold the dust particles to provide clean final product. Application Shri Krishna Double Drive Pulverizer is the perfect machinery fit for grinding of soft, medium and hard minerals into super fine powder. This unit can also be used in Food Industry and Chemical Industry, and Mineral Industry. This unit is also used for grinding of Gram Dal, Tamarind Seed, Wooden items etc. Construction Shri Krishna Double Drive Pulverizer is made from best quality raw materials at our site. The main body of the grinding chamber, whizzer chamber and blower are made of heavy duty cast iron. Every contact part of the main machine is lined with suitable heavy duty lining plates. These lining plates are like a shield to the machine from wear and tear thus increasing the longevity of the machine. The iron nut bolts are provided additionally for wherever required in the machinery. The main shaft runs on Heavy Duty Ball or Roller Bearings. Features Low Power Consumption Automatic Feeding Provided Ideal for Dry Crushing Robust Construction Durable Easy to handle Low Maintenance Best Grinding Efficiency Dust Free Final Product Noise Free Functioning

Impact Pulverizer

Get Price Quote

Manufacturer of Impact Pulverisers are high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals up to the hardness of 3.5 – 4.0 Moh’s such as Minerals, Bentonite, Clays, Limestone, Neeru, Dolomite, Coal, Bauxite, Barytes, Gypsum, China Clay, Soap Stone, Calcite, Pyrophillite, Mehandi, Spices etc. The main mill is equipped with a hopper below which is the STAR-FEEDER actuated by Pawl & Ratchet mechanism. The fine grinding is achieved by compression, shear, abrasion, attrition and impact of hammers beaters on the materials against the replaceable serrated striking plates. The strong suction blower sucks the pulverized product and the air stream inside the mill carries the result product. In between the fan and the grinding chamber (having beaters hammers) is the Whizzer Classifier consisting of blades with tips tapered to conform the contour of whizzer classifier cone. Counter current is set up at the periphery indicated by arrows; it rejects the coarse material back to the grinding chamber for re-grinding. Clamping the whizzer clamp at a suitable position can control fineness. The entire wearing parts consisting of grinding chamber, whizzer classifier and blower are lined with replaceable lining plates.

Automatic Haldi Processing Plant

600,000 Per Piece

Chilli Grinder Machine

Get Price Quote

1 Set (MOQ)

Impact Pulverizers

Get Price Quote

1 Set(s) (MOQ)

We are offering impact pulverizers. singhasini manufacturer of impact pulverisers are high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals up to the hardness of 3.5 � 4.0 moh�s such as minerals, bentonite, clays, limestone, neeru, dolomite, coal, bauxite, barytes, gypsum, china clay, soap stone, calcite, pyrophillite, mehandi, spices etc. The main mill is equipped with a hopper below which is the star-feeder actuated by pawl & ratchet mechanism. The fine grinding is achieved by compression, shear, abrasion, attrition and impact of hammers beaters on the materials against the replaceable serrated striking plates. The strong suction blower sucks the pulverized product and the air stream inside the mill carries the result product. In between the fan and the grinding chamber (having beaters hammers) is the whizzer classifier consisting of blades with tips tapered to conform the contour of whizzer classifier cone. Counter current is set up at the periphery indicated by arrows; it rejects the coarse material back to the grinding chamber for re-grinding. Clamping the whizzer clamp at a suitable position can control fineness. The entire wearing parts consisting of grinding chamber, whizzer classifier and blower are lined with replaceable lining plates. star features: �lower power consumption. �fineness control. �automatic feeder. �low operation & maintenance cost. �high grinding efficiency. �whizzer classifier. �open circuit grinding. �trap iron pocket. �high efficiency cyclone separator. �tubular air bag filter. �continuous silica separator. �high reduction ratio. �heavy duty construction. �sixty year of experience.

impact pulverizer machine

Get Price Quote

Impact Pulveriser's are impact type, high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals upto the hardness of 2.5 - 3.0 Mohs. The Pulveriser is supplied with a hopper below which is a Star Feeder actuated by a Pawl & Ratchet Mechanism. Fine Grinding is achieved by compression, shear, abrasion, attrition and impact of Hammers on the materials against the replaceable Radial Liners. Heavy Duty Construction Low Power Consumption Better Fineness control Automatic Screw Feeder

Hammer Mill Pulverizers

Get Price Quote

Hammer type mill for grinding minerals, chemicals, food items, tamarind seed, saw dust, coconut shell, agarbatti raw material, fullers earth, plaster of paris (calcined gypsum), hydrated lime, herbs etc.

hammer mill pulverizer

Get Price Quote

The Sohanson Pulvmil is an air swept hammer Mill Sohanson Pulverisers are manufactured in various sizes from smallest having one row of hammers using 3 H.P. to the largest size, with four rows of hammers and requirieg 100 H.P. to drive it. Mills are equiped with hopper below which is star feeder, actuated by a pawl - and - ratchet mechanism. A blower is placed on one end of the hammer shaft, between the fan and the hammer, is whizzer, consisting of two are more thin blades with tops tapered to conform to the housing. Distance between blades and housing is regulated by moving the whizzer along the shaft. The classified product passes through the fan and is blown to a cyclone collector where it is discharged into bins or containers. The air goes back to the Pulveriser, completind the cycle. It proper care is used in feed and product handling, the operation can be dust free. Sohanson Pulverisers Units are excellent drying devices and are widely used for simultaneous drying, pulverising, blending, conveying and classifying.

Turmeric Grinding Machine

Get Price Quote

clilli powder

Chilly

Get Price Quote

dhaniya

Pin Mill Machine

Get Price Quote

Pin Mill Machine, industrial mills, Eccentric Sieve Machine