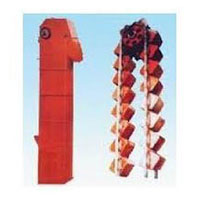

Chain Bucket Elevator

Get Price Quote

We are one of the leading Manufacturers, Exporters and Suppliers of Chain Bucket Elevator in India. We provide these Chain Bucket Elevators in single strand and double strand construction. Chain Bucket Elevator is vertically up conveyor equipped with buckets fitted on chain. The elevator moves in vertical paths between duplex sprockets. It is extensively used for heavy duty, large capacity, big height, nonabrasive material and large lumps. Capacity wise, these elevators are available in duty, medium duty, heavy duty or super capacity types. In fact, these elevators are classified as centrifugal discharge and continuous discharge.

Weigh Filler Machine

Get Price Quote

We are offering weigh filler machine tha machine use in manual filling granual products use for 50 grams to 1 kg., 500 grams to 5 kg., 10 kg. To 50 kg. Filling sisteam devlop as pre reqremetns. machine with weighing sistem plc base or machine use reqrements for air compressor..

Best Deals from Bucket Elevators

Bucket Elevator

Get Price Quote

Range : Automatic Bucket Elevator , Belt Bucket Elevator , Bucket Elevator , Grain Bucket Elevator , Vertical Bucket Elevator Leading Supplier

Bucket Elevator

Get Price Quote

1 Piece (MOQ)

Bucket Elevator

Get Price Quote

We are associated with a group of quality auditors who check the offered lot on several parameters for ensuring quality compliance of the products. Keeping in compliance with the international standards, we ensure that the raw materials used for varied products are 100% certified and quality approved. This helps us in maintaining a set standard of our products. Features : Top quality Very sturdy High strength Smooth functionality Cost efficient Specification : Load Capacity - Vary from different models Material Feature - Heat Resistant

Weigh Filler Machine

40,000 Per No

1 No (MOQ)

Bucket Elevator

Get Price Quote

We are offering bucket elevator. The bucket elevator offered by us is suitable for dusty light aerates, and sticky materials. The bucket elevator that we manufacture, export and supply is used for transferring a huge amount of material from one place to other. Moreover, we are one of the well-established manufacturers and exporters of bucket elevator

Bucket Elevator

Get Price Quote

1 Unit (MOQ)

We are amidst prominent Bucket Elevator Manufacturers and Exporters in Maharashtra. The Bucket Elevator which we are providing to the clients is of Belt & Chain type. Our Bucket Elevator is extensively used for serving the purpose of bulk material handling in various industries. The Bucket Elevator is appreciated in industries like Sugar, Fertilizer, Cement, Agro, Petrochemicals, and Food. The Bucket Elevator is easy to operate and requires low maintenance. Clients can avail the excellent quality Bucket Elevator from us at budget friendly price in the market. Industries Where This Product Is Used Sugar Fertilizer Cement Agro Petrochemicals Food Industries

Bucket Elevator

65,000 - 250,000 Per piece

5 Piece (MOQ)

Bucket Elevator

Get Price Quote

1 Piece (MOQ)

Bucket Elevator

8,000 - 125,000 Per Feet

Bucket Elevator

8,000 - 125,000 Per Feet

Our Bucket Elev4tor P4rts are demanded by numerous industries across the world for the reason that they are the efficient, dependable as well as hygienic for conveying application. Bucket elevator is used for taking the bulk material upward, Distributing. One elevator can feed to many systems requiring only one feed point. It has a Heavy Duty Stainless steel structure and Heavy Duty food grade bucket. The bucket elevator is the enabling technology that permitted the construction of grain elevators.Our team of quality checkers inspects the every batch of the product before supplying to the clients so as to ensure their faultlessness. They have good permanence because of their high abrasion and corrosion resistance, impact resistance and excellent finishing. We offer these at reasonable rates. We are the leading Bucket Elev4tor P4rts Suppliers in India.Technic4l Specifications "Centrifugal” Bucket Elevators operate at higher speeds to discharge the material by centrifugal action out of the buckets into thedischarge spout as the buckets pass over the head pulley/sprocket. Continuous” Bucket Elevators are designed to handle friable,fragile materials to minimize product degradation and damage or to handle sluggish or abrasive material. They are also used to convey light free-flowing matter where aeration of the material must be avoided. Continuous style elevators operate at a lower speed to minimize breakage of friable materials. Buckets are closely spaced on the belt or chain to allow the material to flow over the backside of the proceeding bucket, whose extended sides form a chute to guide the material into the discharge spout. Standard bucket elevators are made out of carbon steel. Elevators for handling material of temperature upto 300°C can be supplied. Close bucket arrangement ensures homogeneous material flow with minimal spillage. Self-supporting design for elevator heights upto 25 meters and external support provided for taller elevators. Chain design is based on the DIN / IS standards. Design for dust and vapor-tight requirements. Application Area : Cement Industry : Clinker , Coal, Fly Ash & Cement Food Industry : Salt Cake, Soda Ash, Soya bean cakes & seeds, Malt, Rice, Wheat. Chemic4l Industry : Stable Bleaching Powder, Hydrated Lime. Power Industry : Fuel Feeders, Coal. Steel Industry : Co-generation Plant & Ash Disposal Plant. P4per Industry: Fly Ash

Bucket Elevator

Get Price Quote

1 Piece (MOQ)

MATECH Bucket Elevators feature heavy duty components, jig welded for easy assembly. All pieces are Mild steel for a durable finish and long, maintenance free life. The Matech design provides the ideal Material discharge for the based on the rated capacities.

Vertical Bucket Elevator

6,800 Per Feet

1 Piece (MOQ)

Bucket Elevator

Get Price Quote

Bucket Elevator

Get Price Quote

We are one of the renowned manufacturers, offering a wide array of Bucket Elevator for sugar industry. Due to their high productivity rate and modernistic features, these Bucket Elevators are highly appreciated and demanded in sugar mills. We use the finest materials and components to manufacture our Bucket Elevators. Our Bucket Elevators are quite sturdy and economical.

Rice Mill Bucket Elevator

15,000 Per Meter

1 Set(s) (MOQ)

As Per Requirement of industries and plant we develop and manufacture Rice Mill Bucket Elevator which can be used as vertical or inclined. This conveyor is Cost effective solution for breakable soft products. It’s an open design, easy to clean and maintain. It has low maintenance and cost. These types of conveyors are ideal for high capacity at low cost.

Bucket Elevators

Get Price Quote

1 piece (MOQ)

Bucket Elevators are the material transfer machines that lifts the material to certain height so that it can be transferred to a further machinery in the production plant.

Rice Mill Bucket Elevator

Get Price Quote

Rice Mill Bucket Elevator that we offer is manufactured using quality approved components and the latest techniques at our well-equipped production unit. It is stringently tests on various quality parameters so as to ensure its smooth functioning and durability. By bringing forth well-tested product, we have become the sought after Manufacturers and Suppliers of Rice Mill Bucket Elevator. One can obtain Rice Mill Bucket Elevator from us in small as well as bulk quantities.

CNC BUCKET ELEVATOR

3,000 Per Feet

10 Feet (MOQ)

Bucket Elevator

27,000 - 100,000 Per piece

1 piece (MOQ)

Bucket Elevator System

300,000 Per Unit

1 Unit (MOQ)

Bucket Elevator

Get Price Quote

1 piece (MOQ)

Bucket Elevator

Get Price Quote

1 piece (MOQ)

Bajaj Bucket Elevators are ideally suited to elevate bulk materials from sluggish to free flowing vertically. These bucket elevators are manufactured for capacities up to 15000 Kg/hr. depending upon the material requirements. Bajaj Bucket Elevators consists of rectangular rigid mild steel housing with a tangential inlet in the bottom section and an inclined outlet in the top section. Bajaj Bucket Elevators are of centrifugal type with rigid seamless mild steel buckets mounted on open ended belts. These are anti static oil repellent in nature. The drive unit comprises of an electrical motor coupled to reduction gear box mounted on the maintenance platforms attached to the top section. Robust construction Completely enclosed for dust free operation Low maintenance Made with superior technical know how Simple Operations BENEFITS Considerable saving in labour cost. Available in different models for specific requirements like bagging, transferring to conveyors etc. Bucket design ensures maximum fill in buckets and prevent discharge interface with proceeding buckets while in operation. Effective inspection windows on intermediate sections. Easy installation facilitated due to quick connection between components. Precise machined head and tail pulleys to facilitate belt movement. Easily operated adjustment devices.

Bucket Elevator

80,000 - 125,000 Per Feet

1 Piece(s) (MOQ)

Bucket Elevator

10,000 - 250,000 Per piece

1 Set(s) (MOQ)

Bucket Elevator

Get Price Quote

1 Piece (MOQ)

mild steel bucket elevator

575,000 Per piece

1 piece (MOQ)

mild steel bucket elevator

100,000 - 200,000 Per piece

1 piece (MOQ)

Continuous Discharge Bucket Elevators

Get Price Quote

We, as preeminent Manufacturer & Exporter, are engaged in making available Continuous Discharge Bucket Elevators in the global market. Our Continuous Discharge Bucket Elevators come with all the safety features and widely preferred. Our Continuous Discharge Bucket Elevators are competitively priced for the ease of the buyers. More about Continuous Discharge Bucket Elevators : The Continuous Discharge Bucket Elevators are often used to handle sluggish, aerated materials having a lumpy texture. These elevators are designed in such a manner that the buckets are continuously spaced (traveling at speed slower than the centrifugal type), so that, the fronts and extended sides form a chute as they pass around the head terminal, gravity causes the material to gently flow out of the buckets and down the chute formed by the preceding.