Stainless Steel Storage Tank

Get Price Quote

1 Piece (MOQ)

Sodium Hypochlorite Plant

Get Price Quote

1 Pieces (MOQ)

Best Deals from Chemical Plants

Stainless Steel Storage Tank

20,000 Per Piece

1 Piece(s) (MOQ)

Activated Carbon Making Plant

20,000,000 Per Unit

1 Unit (MOQ)

Hydrated Lime Plant

1,000,000 Per Set

1 Set(s) (MOQ)

Features: Used for grinding applications Finished in the perfect manner Reliable and easy to install

Chemical Dosing Plant

Get Price Quote

1 Unit (MOQ)

Chemical Industry Effluent Treatment Plant

2,350,000 Per Set

1 Set (MOQ)

Stainless Steel Tank

49,000 Per Piece

1 Piece (MOQ)

Sulphuric Acid Manufacturing Plant

Get Price Quote

1 Set (MOQ)

BVR Provides complete turnkey solutions for the manufacturing plant projects of Sulphuric acid from Sulphur & allied products, for commercial and laboratory grades. Our services include preparation of preliminary estimation, pre-feasibility reports, DPR, Plant technology, know-how, basic & detail engineering, project execution, procurement, fabrication, erection supervision and plant commissioning.

Bitumen Derivatives Plant

Get Price Quote

1 Piece (MOQ)

Stripping Column

800,000 Per piece

A Stripping Column is a chemical equipment used for physical separation, where one or more components are removed from a liquid stream by a vapor stream. In industrial applications, the liquid and vapor streams can have co-current or countercurrent flows. Stripping works on the basis of mass transfer.

Chemical Processing Machines

Get Price Quote

Reckoned for our extensive array of products, we efficiently serve our customers from Uttar Pradesh(India). Our organization has all the essential logistic resources and links to ensure on schedule delivery of order(s).

Nitric Acid Concentration Plant

Get Price Quote

Stainless Steel Storage Tank

Get Price Quote

1 Piece (MOQ)

Stainless Steel Storage Tanks

250,000 Per

10 Metric Ton (MOQ)

Steam Activated Carbon Plant

Get Price Quote

1 Piece (MOQ)

We are manufacturing all types Steam Activated Carbon Plant. Steam activated carbon plant applied for manufacturing Wood charcoal based activated carbon & Coconut shell based Activated carbon. With our excellence in this field, we share forefront for supplying world-class array of products from Rajkot(India). Feel free to approach us, if seeking for top-of-the-line quality Steam Activated Carbon Plant!

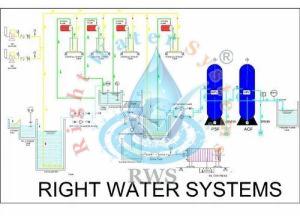

Chemical Water Treatment Plant

Get Price Quote

1 Piece (MOQ)

Stainless Steel Tank

Get Price Quote

5 Piece (MOQ)

Mineral Processing Plant

1,500,000 Per Piece

1 Piece (MOQ)

We are the Leading Manufacturer and Supplier Mineral Processing Plants in Chennai, Tamilnadu, India.These products find application in various iron ores, copper ores, manganese ores, and tin ores. The plants offered are manufactured using the latest technology and sophisticated plant machinery, to ensure high standards of quality. These products can be custom designed as per the requirements of our valuable customers.Features: Highly reliable Easy to install and operate Reasonable Price Compact design

Stainless Steel Storage Tank

5,000 Per Piece

1 Piece (MOQ)