Injection Molds

Get Price Quote

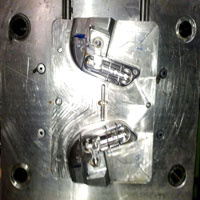

We offer Injection Moulds that are designed as per the set standards by using high-grade raw material. Injection Mould is a 2 cavity loose core metal insert injection Mould for recliner seat actuator handle totally designed and manufactured by us. Core and cavities are made of vacuum heat-treated P20 material and the die set is of C45 material. Specialties : Excellent quality Sturdy make Durable Reliable

Plastic Injection Moulds for Irrigation Parts

Get Price Quote

10 Kg (MOQ)

Backed with immense experience, we are able to offer accurately dimensioned Plastic Injection Moulds for Irrigation Parts. We are reckoned for manufacturing and supplying durable & high quality Plastic Injection Moulds for Irrigation Parts. For the fabrication of our Injection Moulds, we make use of superior grade plastic and hi-tech machines. Buyers can obtain bulk quantities of Injection Moulds at reasonable rates from us.

Best Deals from Injection Molding

Plastic Injection Mold

25,000 Per piece

1 piece (MOQ)

products are manufactured using high quality raw metals and cutting edge technology as per the set industry standards

Textile Plastic Bobbin Injection Mold

65,000 Per nos

1 Piece (MOQ)

Vertical Injection Molding (Single Slide)

Get Price Quote

Salient Features Micro processor based Techmation / Porcheson controller. Nitrided steel screw & barrel directly driven by high torque hyd. motor Multi stage speed pressure & position for injection & clamping Screw cold start prevention Close loop barrel temperature control Molding condition monitoring with alarm Low pressure mold protection device Hydraulic RAM type clamping system Safety sensor for machine & operator safety Automatic purge system Emergency stop Proportional pressure & flow control valves Barrel cover Set of easy damage parts Level Pads / Tool kit set Steel Hopper

Injection Molding

Get Price Quote

We manufacture plastic injection molded objects that are used in a wide range of products, including medical devices, electronics, aerospace, transportation, packaging, construction, and many other industries and consumer products.

Plastic Injection Mould

Get Price Quote

Matching up with the ever increasing requirements of the customers, our company is engaged in providing plastic Injuction Mould Features: Corrosion resistant Accurate results High tensile strength

Plastic Cap Injection Mould

Get Price Quote

1 Piece (MOQ)

Injection Moulds

Get Price Quote

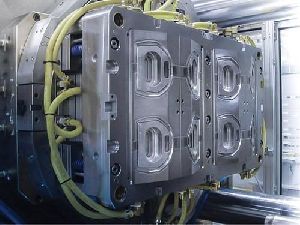

We offer Injection Molds in materials, sizes, and shapes as desired by our clients. The Injection Moulds we offer are dimensionally accurate and can be used repeatedly in the manufacturer of whatever product you chose to use it for. The Injection moulds we offer ensure that your finished product turns out impeccably and has a professional and uniform finish. We are a leading manufacturer and supplier from Mumbai, Maharashtra, India.

Injection Moulds

Get Price Quote

The company is a highly acclaimed Manufacturer, Exporter, and Supplier of Injection Moulds. Offering high quality Plastic Injection Moulds for tool rooms, the company comes up with a range that is highly durable and packed in carton boxes and plastic bags. The Injection Moulds are used extensively in automotive, electrical, and medical sectors as well as many other industries. The Injection Moulds are made using the high-quality plastic grades like PP and PVC.

Injection Moulding

19,000 - 20,000 Per Pair

5000 Pack (MOQ)

100 Unit Allergan Botox Injection 19,680 - 20,500 / Pack Get Latest Price MOQ20 Pack Country of OriginIndia 100 Unit Allergan Botox Injection100 Unit Allergan Botox Injection 100 Unit Allergan Botox Injection100 Unit Allergan Botox Injection 100 Unit Allergan Botox Injection100 Unit Allergan Botox Injection Supply TypeExporter, Retailer, Distributor, Trader

Metal Injection Molding

Get Price Quote

We are offering metal injection molding—mim—offers a manufacturing capability for producing complex shapes in large quantities. The process utilizes fine metal powders (typically less than 20 micrometers) which are custom formulated with a binder (various thermoplastics, waxes, and other materials) into a feedstock which is granulated and then fed into a cavity (or multiple cavities) of a conventional injection molding machine. After the “green” component is removed, most of the binder is extracted by thermal or solvent processing and the rest is removed as the component is sintered (solid-state diffused) in a controlled-atmosphere furnace. The mim process is very similar to plastic injection molding and high-pressure die casting, and it can produce much the same shapes and configuration features. However, it is limited to relatively small, highly complex parts that otherwise would require extensive finish machining or assembly operations if made by any other metal-forming process. Advantages: the advantages of the metal injection molding process lie in its capability to produce mechanical properties nearly equivalent to wrought materials, while being a net-shape process technology with good dimensional tolerance control. Metal injection molded parts offer a nearly unlimited shape and geometric-feature capability, with high production rates possible through the use of multi-cavity tooling. Materials range the metal injection molding industry can manufacture an extremely wide variety of metal alloy compositions for use in your application. The alloy families shown below make up a broad representation of the spectrum of alloys which can behave been produced for various applications. If you do not see the exact alloy or alloy family shown on our extensive list in which you have interest, please contact your supplier in order to see if the alloy or a substitute alloy is available. Working closely with your supplier will enable you to find the best solution for your application. The most common alloy families are: iron, low-alloy steels, stainless steels other alloys: aluminum alloys, bio-compatible alloys, carbides, ceramics, cobalt-based alloys, controlled-expansion alloys, copper and copper alloys, hardmetals, heavy-metal alloys, magnetic alloys (soft and hard), nickel-based alloys, precious metals, reactive metals, shape-memory alloys, specialty alloys, titanium and titanium alloys, tool steels.

HDPE grinding injection molding

50 Per Kilogram

2 Metric Ton (MOQ)

we have HDPE regrind injection molding to sell. We have imported regrind, as well as industrial scrap for selling in bulk.

Single USB Cable Injection Mould

3,000 Per piece

5000 piece (MOQ)

Injection Molds

80,000 - 200,000 Per piece

"At our forefront in the industry, our Injection Mold Die Manufacturing Service distinguishes itself by delivering precision-engineered, custom mold dies across a spectrum of sectors like automotive, healthcare, and consumer products. Harnessing advanced CAD/CAM technology, cutting-edge machinery, and a deep commitment to quality, we tailor our solutions to meet the unique demands of each project."

Plastic Injection Mould

800,000 Per Piece

Plastic Injection Mould

50,000 Per Piece

washing machine Injection Mould

Get Price Quote

500 piece (MOQ)

Plastic Injection Molds

32,000 Per piece

1 piece (MOQ)

Plastic Injection Spoon Mould

Get Price Quote

Plastic Injection Mold

Get Price Quote

1 Set(s) (MOQ)

We are offering plastic injection mold. To give life to a mould along with professional ability of the staff, huge expenditure on human resource and technology are required. The user can gain from superior productivity and stable quality if high level of operation is maintained with the support of innovation and construction technology which supple a mould of the highest accuracy and dependability.

eva injection moulds

Get Price Quote

Specifications 1. hot and cold pressing outsole 2. sport outsole 3.pvc shoe 4.eva shoe mould 5.rb tpr sole mould

plastic injection blow mould

70,000 Per Piece

Reaction Injection Mold

Get Price Quote

Reaction Injection Molding (RIM) injects a rapid-cure resin and a catalyst into the mold in two separate streams. Mixing, and the resulting chemical reaction, occur in the mold instead of in a dispensing head. Automotive industry suppliers have combined structural RIM (SRIM) with rapid preforming methods to fabricate structural parts that don’t require a Class A finish. Programmable robots have become a common means to spray a chopped fiberglass/binder combination onto a vacuum-equipped preform screen or mold. Robotic sprayup can be directed to control fiber orientation. A related technology, dry fiber placement, combines stitched preforms and RTM. Fiber volumes of up to 68% are possible, and automated controls ensure low voids and consistent preform reproduction, without the need for trimming.

Plastic Tray Injection Mould

Get Price Quote

Plastic Coat Hanger Injection Mold

Get Price Quote

The organization is supported by systematized packaging system which assists us in meeting the specific packaging requirements of the clients with ease. Also, we ensure zero damage to the products. We stringently make complete arrangements for the vigil examination of the inputs used for the products. By this, we are capable of bringing forth reliable products that are presented after complete inspection and examination by the experts.

Plastic Injection Moulds

Get Price Quote

Can manufacture any plastic injection mould material : ms, en, wps, ohns, starwex etc single or multi cavities suitable to hand moulding machine, vertical hydraulic injection moulding machine or horizontal hydraulic injection moulding machine.

Injection Moulds

20,000 Per Piece

Plastic Injection Mould

99,000 - 100,000 Per Piece

Plastic Injection Moulds

100 Per piece

1000 piece (MOQ)

Sir We are Plastic Mold Manufacturer and Plastic Part manufacturer, we will do customized service