air shower controller

13,500 Per Piece

1 Piece (MOQ)

The Air Shower Controller is a supporting device for the clean workshops & the assembly clean room , is use to blow the dusts attached to the surface of the people & objects entering the clean work shop, & also functions as an air brake to prevent non purified air from entering the clean area. The Air Shower Controller Systems the sequential locking & release of the doors, & controls the blower. The two door are interlocked such that doors cannot be open at the same time, to prevent pressure losses & cross contamination. INSTEC INDIA Air Shower interlocking systems achieve this by preventing simultaneous access of door, also havingset able showertime & manyfeatures. Features: Advanced Micro controller based. Easy to installation & user friendly wiring. Supports Emergency & fire alarm Stations. Softtouch Membrane keypad. Door status indication with LED as well as LCD Display. System can also be connect to Building Management. Delay between door openings 10 Sec System (BMS). Auto close time is 10 Sec. Air Shower Controller. Facility available to read feed back from Magnetic Read Sensors. Timer facility for shower(Blower on time). Supports entryfrom Exitdoors. OPTIONAL FEATURES Supports Access control module interface. Available Doors Real Time Event Logging and output to PC Connectivity. DoorAccess Panel Inputs & Outputs Inputs : 2 Nos. switches per door. Outputs :2Nos. led indicator per switch. Control Card Digital Inputs & Outputs Inputs : 1Nos. per door. Outputs : 4Nos. relay output 230V/ 5 A. Keys & Programming 4 Soft touch Programming keys Programmable Delay between each door 0 to 99 Sec. Programmable various Timer for controlling action. Non-Volatile Flash Memory.

Stem Type Thermostat

Get Price Quote

100 Piece (MOQ)

Best Deals from Industrial Refrigeration Systems

Thermal Printers

5,000 - 7,500 Per piece

All kind of print sale Ane service

Evaporative Condenser

300,000 Per Set

1 Set (MOQ)

An evaporative condenser is a condenser integrated into a cooling tower which rejects the latent heat of condensation of refrigerant (Ammonia/Freon) through a coil to the surroundings by means of evaporation. Water sprayed onto the coil exchanges heat with the refrigerant. A small quantity of water is evaporated into the air thereby cooling the remaining water cascading to the basin at the bottom. Post evaporation the saturated air passes through the drift eliminators and then forced out using a fan. Construction And Working Of Evaporative Condenser : In evaporative condensers, both air and water are used to extract heat from the condensing refrigerant. Figure shows the schematic of an evaporative condenser. Evaporative condensers combine the features of a cooling tower and water-cooled condenser in a single unit. In these condensers, the water is sprayed from top part on a bank of tubes carrying the refrigerant and air is induced upwards. There is a thin water film around the condenser tubes from which evaporative cooling takes place. The heat transfer coefficient for evaporative cooling is very large. Hence, the refrigeration system can be operated at low condensing temperatures (about 11 to 13 K above the wet bulb temperature of air). The water spray counter current to the airflow acts as cooling tower. The role of air is primarily to increase the rate of evaporation of water. The required air flow rates are in the range of 350 to 500 m3/h per TR of refrigeration capacity.

Industrial Condenser

Get Price Quote

1 Piece (MOQ)

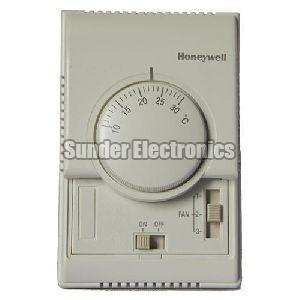

HONEYWELL Thermostat

Get Price Quote

Refrigeration System

Get Price Quote

Shell and Tube Condenser

Get Price Quote

1 Piece (MOQ)

Shell and Tube Condenser, Heat Exchanger used for industrial, Herbal Extraction Plants, Pharmaceutical Plants and Chemical Plants. Condenser used in Herbal Extraction Plant, Phyto Extraction Plant for cooling vapors of product.How it worksA shell and tube exchanger consists of a number of tubes mounted inside a cylindrical shell. Vapor runs through the tubes, and water flows over the tubes (through the shell) to transfer heat between the two.These Shell and Tube Condensers are manufactured from high-grade quality material and are easily available at affordable prices. Various Sizes Stainless Steel Options Custom Configurations Highly efficient Easy to install. Leak-Proof. Highly durable. Low maintenance. Operate trouble-free.

Mens Knitted Thermals

Get Price Quote

500 Piece (MOQ)

water cooled condenser

50,000 - 120,000 Per Piece

1 Piece (MOQ)

Premier offers cleanable Shell & Tube Integrally Finned Water Cooled Condensers from 3TR to 200TR capacity. These Condensers are built in a wide variety of sizes from 6 inch to 24 inch in diameter. Length vary from 3 feet to 20 feet over the tube heads.The Condensers are designed for a pressure of 20 Kg per sq.cm gauge on shellside and 7 Kg per sq.cm gauge on water side. They are tested upto 28 Kg per sq.cm gauge on the shell side & 10 Kg. per sq.cm gauge on water side. The Condensers are fabricated as per TEMA / ASME unfired pressure vessels codes & ASHRAE standards requirements. Condensers for sea water marine application or with steels shells are also offered & designed as per customer specific requirements.

Industrial Condensers

7,500 - 3,000,000 Per Piece

1 Piece (MOQ)

Industrial Condensers are devices or units used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Industrial Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Our Industrial Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many Industrial Condensers. Used In Industries Like : Petrochemicals Refineries Dairy products Chemicals Paper Fertilizers Food

Ice Bank Tank

Get Price Quote

1 Piece (MOQ)

Digital Touch Screen Programmable Thermostat with Heat Pump Control

Get Price Quote

Steam Condenser

Get Price Quote

1 Piece (MOQ)

We are a trustworthy Manufacturer, Exporter & Supplier of Steam Condenser. Steam Condenser is used in power plants helping the turbine to condense the steam. The Steam Condenser recycles the steam as boiler feed water to Boilers. Based on thermal and mechanical designing, we manufacture Steam Condenser in various sizes and specifications as per the requirements of the clients. Generally the tubes used in Steam Condenser are of Admiralty Brass/Cupro-Nickel (90:10)/SS 304 quality depending upon the type of cooling water available, while rest of the material is of Carbon Steel. We provide Steam Condenser with water boxes and also do re-tubing of the Steam Condenser at the site.

Dual Enclosure Thermostat

1,000 Per Piece

1000 Piece (MOQ)

Features: Two thermostats in one unit one Normally Closed (NC) & one Normally Open (NO) Each with wide adjustable temperature range DIN rail mountable ZSR-011 Dual Thermostat houses two separate thermostats, allowing the independent control of heating and cooling or other equipment. Both thermostats offer wide adjustment ranges and are color coded for easy function recognition.

Cold Storage Refrigeration System

200,000 Per Piece

1 Piece (MOQ)

Dump Condenser

Get Price Quote

Dump Condensers are used to recover large amounts of steam that may otherwise be vented to the atmosphere. During fluctuating steam loads, turbine trip off, turbine start-up,or bypass, the excess steam that would ordinarily be vented can be diverted to a dump condenser. Dump Condensers may also be used for process plants when upset demand conditions occur.A dump condenser is required when the steam consumption needs to be drastically reduced in a very short period of time and when the boiler cannot follow this variation.Features : Water-cooled Dump Condensers Fabrication and design typically to Heat Exchange Institute Standard (HEI), ASME Code, and can include TEMA, Seismic Codes, and other specifications. Designs to eliminate excessive vibrations and water hammer Standard materials are carbon steel with stainless steel tubes. Special materials are available for severe duty or other applications.Dump Condenser can be furnished as a system which may consist of Steam Pressure/Temperature Reducing Station and Condensate Recovery System which includes Level Controls, Condensate Pumps, and Electrical Control Panel for automaticoperation.

Steam Iron Covers

Get Price Quote

Being one of the leading names in the industry, we are instrumental in offering Steam Iron Covers to the clients. We are based in Haryana, India. Our clients can avail them in various specifications. Owing to their brilliant features like seamless finish, dimensional accuracy, durability, and long life, these are highly appreciated by our clients. We have enough capacity to deliver them in bulk quantities, within the promised time frame.

Condensing Unit

Get Price Quote

We stand amidst the notable Manufacturers & Suppliers of Condensing Unit. Reliability and low energy costs are a crucial requirement in the Food service industry. With the proven reliability and efficiency, we bring forth a wide range of Condensing Unit in various models. The Condensing Unit we supply is attributed with rigid construction, long working life, excellent performance and high functionality. Application Areas Cold rooms Bulk milk coolers Chillers Pharmaceutical industry

Marine Refrigeration and Air Conditioning Condenser

Get Price Quote

1 Piece (MOQ)