Polyester Reinforced Rubber Flat Belts

2,000 - 10,000 Per piece

1 Piece (MOQ)

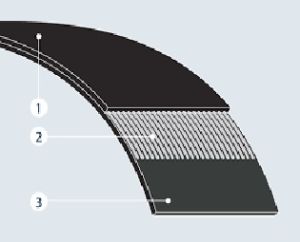

VSI ENTERPRISES is one of the leading Manufacturers and suppliers of flat belts, Power Transmition flat belts are manufactured with Rubber - Polyester Fabric and Rubber, which is more flexible and 25 % higher Strength as compare to classical Nylon sand with flat belts. For this type Low tensioning arrangement required because of high strength of load carrying member. Our flat belts are work flawlessly during their life span. Power Transmition flat belts Construction: 1) Top Cover for covering or Friction ( Rubber) 2) Core Member is for load carrying ( High Strength Polyester) 3) Bottom cover is for Friction ( Rubber) Belt Types : GG : both side rubber coating We are also manufacturing and supplying truly endless flat belt for very high RPM and temperature. Application Area: Textile industries, Pulp & paper industries, Iron & steel industries, Machine tools Automotive Stamping Industries, Paper & printing industries

Heavy Duty Rubber Conveyor Belt

Get Price Quote

With our fast delivery network, we can easily meet expected delivery deadline of the clients. So, what are you waiting for, place orders now! Located in Pallipalayam(India), we ensure safe and secure deliveries, throughout the country, within the agreed time frame.

Best Deals from Rubber Timing Belts

Black Heat Resistant Rubber Conveyor Belt

720 - 2,400 Per Meter

50 Meter (MOQ)

Rubber Belt Unit.

Get Price Quote

1 Piece (MOQ)

Rubber Belt Shrinking Unit for giving mechanical shrinkage to the fabric. Stainless Steel Plate fabricated main roller and Stainless Steel cladded planket guiding and squeezing rollers for longer service life. Pneumatic squeezing device doesnot allow the water to carry over on the blanket surface. Blanket cooling arrangement on both inside and outside surface of blanket and one more in the inner side after the squeezing for lubricaton eliminates the possibilities of frequent cuts on both sides. Motorised blanket pressing and tensioning attachment can be supplied optionally. The machine is suitable for Synthetic Sarees, Dress Materials, PV Suitings & Shirting. Machines are available from 1500 mm to 3400 mm working width.

Timing Belt HTD800-8M (Thin Blade Scorer Machine)

800 - 2,000 Per Piece

1 Piece(s) (MOQ)

HTD800-8M

Rubber Conveyor Belts

800 - 1,800 Per Meter

50 Meter (MOQ)

Sandhya Enterprises supplier of Rubber Conveyor Belts. size: 1.6mm Thickness 2Ply to 3ply 2.8.0mm Thickness 2ply to 3ply 3.10.mm Thickness 3 to 4ply 4.12.0mm Thickness 3 to 4ply Width 100mm to 1500mm. Use for RMC Plant , Cement Plant and Crusher Plant.Conveyor belts are mechanical devices used to transport materials or objects from one point to another in a continuous manner. They are widely used in various industries, including manufacturing, mining, agriculture, logistics, and more. Conveyor belts consist of a continuous loop of flexible material that is driven by pulleys or rollers, allowing for efficient movement of goods or materials. Here are some key features and components of conveyor belts: 1. Belt material: Conveyor belts are typically made from various materials depending on the specific application requirements. Common belt materials include rubber, PVC (polyvinyl chloride), polyester, nylon, metal, or a combination of these materials. The choice of material depends on factors such as the type of material being conveyed, its weight, abrasion resistance, temperature resistance, and environmental conditions. 2. Belt structure: Conveyor belts are constructed with layers of material that provide strength, flexibility, and durability. The most common belt structure consists of a carcass, which is the core layer that provides tensile strength, and one or more cover layers that protect the carcass from wear, abrasion, and external elements. 3. Drive system: Conveyor belts are driven by a motorized pulley, drum, or a set of rollers. The drive system applies power to the belt, causing it to move. The drive can be located at either end of the conveyor or at intermediate points, depending on the length and configuration of the conveyor system. 4. Rollers and idlers: Conveyor belts run on rollers or idlers, which support and guide the belt along the conveyor path. These rollers can be made of steel, rubber, or other materials, and are designed to minimize friction and facilitate smooth movement of the belt. 5. Belt tracking system: To ensure proper alignment and tracking of the belt, conveyor systems may include a tracking mechanism. This can be in the form of adjustable idlers or automated systems that help keep the belt centered and aligned on the conveyor. 6. Accessories: Various accessories can be added to conveyor belts to enhance their functionality and safety. These may include belt cleaners to remove debris and material buildup, belt fasteners for joining belt ends, skirt boards to contain material on the belt, and safety devices such as emergency stop switches and belt misalignment sensors. 7. Specialized belts: There are specialized conveyor belts designed for specific applications, such as heat-resistant belts for high-temperature environments, food-grade belts for the food industry, oil-resistant belts for the mining industry, and more. These belts are formulated with specific materials and features to meet the unique requirements of their respective industries. Proper maintenance and regular inspection of conveyor belts are crucial to ensure their efficient and safe operation. This includes monitoring belt tension, checking for wear or damage, and performing routine cleaning and lubrication. When selecting a conveyor belt, it is important to consider factors such as the type and weight of the material being conveyed, the operating conditions (including temperature, humidity, and presence of chemicals), the required speed and capacity, and any specific industry regulations or standards. Consulting with experienced conveyor belt suppliers or manufacturers can help in choosing the appropriate belt type and configuration for your specific application needs.

Rubber Conveyor Belt

Get Price Quote

50 Meter (MOQ)

Rubber Conveyor Belt

650 - 3,500 Per Meter

5 meter (MOQ)

Chevron Rubber Conveyor Belt

Get Price Quote

100 Meter (MOQ)

Rubber Fitness Machine Belts

Get Price Quote

We can produce high quality jointless belts to be used in various fitness machines. We work with the client to achieve the correct tension to suit their machine requirements.

Rubber Conveyor Belt

Get Price Quote

20000 Meter (MOQ)

Rubber Transmission Belts

60 - 300 Per Feet

rubber belt

Get Price Quote

We make certain that the offered array of products is sternly packed and delivered safely to the customers' stated address and that too in the committed time span. We understand that the superior grade raw material is essential for the development of high quality products. And, for maintaining these standards, we have adopted several quality measures for ensuring the quality.

Rubber Conveyor Belt

Get Price Quote

We make Conveyor Rubber belts from 400mm until 1600mm widths in plies ranging from 3 to 10. Our belts are also exported world-wide in Covers quality ranging from N17 , M24, OR , SHR etc. We also make Rough Top belts as well as Wavy top belts for packaging industry

Rubber Chevron Conveyor Belt

1,200 - 3,800 Per Meter

500 Meter (MOQ)

APPLICATION Patterned conveyor belt is an inclination conveyor belt composed of Patterned work surface, flat non working surface and core. It is suitable for conveying powder, granular, small pieces materials with the inclination of 0 ~ 40 ° to prevent the material from falling. We often apply it in: conveying bulk material in stone crushing plant, waste recycling plant, sand and gravel aggregate manufacturing plant, thermal power station, concrete mixer plant, mine mining plant, metallurgy plant, port / terminals/ dockside, etc FEATURES 1. There is no joint in belt carcass 2. Long service life 3. Cleats and top cover rubber are vulcanized integrally 3. Cleat pattern, angle and pitch are designed elaborately 4. There are open type and closed type, suitable for bulk or bagged materials such as powder and granule with incline less than 45°. Type Cleat Size (mm) Belt Width (mm) CV, full width Cleat Height=5; 10 Cleat Width= full width Cleat Pitch=100 300-1200 CV, closed Cleat Height=15 Cleat Width=300; 450 Cleat Pitch=250; 300 400-1200 CV, open Cleat Height=15 Cleat Width=385; 600; 750 Cleat Pitch=250 450-1200 CP, open Cleat Height=17 Cleat Width=300; 440; 550; 630; 750; 950 Cleat Pitch=330 400-1400 CP, open & closed Cleat Height=25 Cleat Width=450; 550; 750 Cleat Pitch=330 500-1200 CP, open Cleat Height=32 Cleat Width=580; 630; 750 Cleat Pitch=330 700-1400 U, closed Cleat Height=15; 32 Cleat Width=550; 700 Cleat Pitch=350; 400 650-1200 Multi-V, full width Cleat Height=6 Cleat Width= full belt width Cleat Pitch= 76 500-2000

Rubber Conveyor Belt

35,000 Per Piece

5 Piece (MOQ)

GIMPEX SUPRIME Rubber v belt

500 - 20,000 Per pcs

full range of gimpex suprime v belt

rubber cogged belts

Get Price Quote

50 Piece (MOQ)

Premier Rubber Mills is actively engaged in the manufacturing of superior quality Cogged Belts in the international market. The Raw Edge Cogged Belts that we offer are designed and developed for efficient transmission of the materials from one place to another with low stretch on the belt. Rubber Cogged Belts are fabricated from high quality rubber components and imported raw material ensuring maximum resistance to heat and wear-and- tear. Besides, we are one of the prime Cogged Belts Manufacturer and Exporter in India.

Rubber Conveyor Belt

Get Price Quote

Rubber V Belt

50 Per piece

This is the Continental branded v-belts.