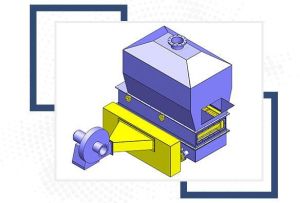

Noback and Co2 Process Sand Cooler

Get Price Quote

1 Piece (MOQ)

Features: Various types of coolers like water-spray type, fluidised bed type, vertical counter blow type are available. Water-spray type: Fastest cooling method available. Ideal in case, where additional moisture is desirable. No need for any additional airflow. Fluidised bed type: Ideal for fine grain and powder material for cooling. Cool air covers most of the grain surface for rapid cooling. Available for No-Bake and Lost Foam Process. Fluidization is done with a controlled amount of airflow help to remove dust and fines from the sand. Provision of a temperature sensing system for output sand. Vertical counter blow type: Gives counterflow to the vertically falling sand (or any grainy material). Consumes less power and airflow compared to Fluidised bed type sand cooler. Ideal for good availability of height.

Sand Cooler

Get Price Quote

Best Deals from Sand Cooler

Sand Cooler

Get Price Quote

We are offering sand cooler.we bring forth superior quality sand coolers to our clients. Our sand cooler has many striking features which makes it highly demanded in the market. Our sand coolers are manufactured from the best quality components and are highly efficient. These sand coolers can be obtained at market leading prices. comprises of induced draft blowerfluidized bed chamberdust extraction and collection system with cyclone separatorforced draft blowerbag type dust collector

Sand Cooler

Get Price Quote

We offer Sand Coolers that are widely used in the construction industry. Our precisely engineered coolers are robust and are offered in varied specifications.

Sand Cooler

Get Price Quote

Sand Cooler

Get Price Quote

Feature : Low moisture level Reduce the rejection of casting Increase productivity Excellent surface finish

Sand Cooler

Get Price Quote

Return Sand Temperature, after the vibratory shake out in a mechanized green sand foundry is around ZOOGC. The sand temperature is highest arbacent to the metal surface and lowest away job it. The quantity of heat to be removed depends on the sand to metal ratio and the holding time of metal in the mould. The return sand temperature at the inlet of the cooled after passing through conveyor is around 1 OOOC. Mould of good quality and clean casting surface require well cooled sand,Sand Cooling requires a continuous and uniform flow to achieve the uniform flow and compensate for irregular Sand supply the sieved hot return sand is stored in a surge hopper from there; a belt transports the hot sand to the cooling conveyor which is designed with a perforated bottom plate. Fresh air is blown through the preparation holes and at the same time water is sprayed on to the sand from nozzles located above the conveyor vibrations of the conveyor and turbulence caused by the air blown through ensure that sand water mix well so that The water evaporates and the sand is cooled. The belt, the cooling conveyor and the sand spraying unit are controlled by level indicators located in the surge hopper the plant operates only if the sand in the surge hopper is between the maximum and minimum level.

FOUNDRY VIBRO SAND COOLER

18,000 Per Piece

1 Piece (MOQ)

Sand Cooler

600,000 - 1,000,000 Per Piece

Vibro Sand Cooler

Get Price Quote

Foundry Sand Cooler

10,000 Per Piece

Sand Cooler

Get Price Quote

Sand Cooler

Get Price Quote

Abirami fluidized bed sand cooler ensures effective cooling of sand by double effect of water and air, during the process the sand is also conditioned.

Sand Cooler

Get Price Quote

Specially designed for hot conditions like Asian and African continentals. Fluid bed can effectively cool and classify reclaimed sand. Low maintenance and effective design Fluidization is done with controlled amount of air flow helps to remove dust and fines from sand. Temperature difference of 40 - 60 ° can be archived in normal conditions.

Rotary Sand Cooler

Get Price Quote

ROTARY Drum Sand Cooler

Get Price Quote

The almost ZERO maintenance equipment for cooling HOT return sand after Shake-out for small-medium-large foundries. BMM make ROTARY Drum Sand Cooler is the most efficient & serving successfully to the foundry industry from many decades. Its robust & durable construction helps the foundries to go on using for years to come without any break down. It also helps in homogenous the sand during the transit inside the drum chamber.

Fluidized Sand Cooler

Get Price Quote

Ganesh fluidized sand cooler is specially designed to have a dust free return sand at constant temperature ensuring good mould quality.• Ganesh fluidized sand cooler gives rapid and efficient cooling of sand.• Capacity 1Ton per hour to 20 ton per hour.

Sand Cooler

Get Price Quote

The sand final temperature and moisture, accurately controlled, improves the quality and surface of castings, decreasing the rate of rejects. • Fluidized Sand Coolers cool and homogenize the sand in continuous operation and provide, independently of sand inlet temperature, an evenly cooled and dampened material of uniform quality. The +/- 0,3% tolerance is so little that the intensive mixer will be considerably relieved. • They are equipped with a special fluid bed stainless steel screen deck which allows the air to pass through the sand layer. The automatic moisture control system has the task to ensure the optimum water addition and to avoid over or lower moistening. • The biggest model in the range is 2500 mm wide and 10000 mm long and can handle 200 ton/h sand reducing the temperature from 140°C down to 40°C with a range of moisture in between 1.8 – 2.5 %. Product ranges from capacity of 10 tons/hr to 80 tons/hr.

Sand Cooler

Get Price Quote

sand cooler is specially designed to have a dust free return sand at constant temperature ensuring good mould quality. Quick cooling by double effect of water & air cooling. Size Information: Capacity 1 Ton per hour to 20 ton per hour.

Sand Coolers

Get Price Quote