Vickers Hardness Tester

1 Piece (MOQ)

Wide Testing Range from Soft metal to medium hardness Steel. Motorized loading/unloading. Built in Projection Screen to get accurate Result Features : Testing range is very wide, from soft metal such as lead, upto the hardest, like hard steel. Same hardness number is obtained on the same specimen, regardless of the load applied. The indication is tiny and allows testing of a precision finished part. Loading and unloading cycle is motorized. Thin sheet metal is perfectly tested because the load applied very small. Built-in projection screen to get accurate results. Application Our Vickers Hardness Tester is a simple and accurate means to produce and measure the diamond indentation. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard and their accurate results are widely acclaimed. These testers strictly confirm to IS: 1501-2 and ISO 6507-2. Construction The robust machine frame is designed to accommodate the high precision loading system and an optical projection screen. Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond indenter by means of a lever and weights. After a specific laps of time, the load is removed automatically. The objective is indexed with the test piece and the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer thimble of the projection screen.

...more

Universal Testing Machine

342,000 - 866,000 Per Piece

1 Piece (MOQ)

FEATURES Loading accuracy as high as ±1%. Straining at variable speeds to suit wide range of materials. Printer & PC graphs enable study the behavior of the material. Motor Driven threaded columns for quick effortless adjustment rapid fixing of test specimen. Simply in reading because of digital readouts. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standard specimens as well as structures. RS 232 serial port to transfer data to computer for analysis/storage evaluation etc. Manual Control & release valve Operation. Safe operation ensured by means of safety devices. APPLICATIONS Universal Testing Machine is designed for testing metals and other materials under Tension, Compression, Bending, Transverse and shearloads. Hardness test on metals can also be conducted ACCURACY & CALIBRATION All Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS: 1828-1975. Universal Testing Machines Comply with grade "A" of BS: 1610: 1964 and grade 1.0 of IS -1828-1975 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the Maximum permissible error is 0.2% of the full reading. PRINCIPLE OF OPERATION Operation of the machine is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The system is ideal since it replaces transmission of load: through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self - lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through leverage to the pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of the specimen. MACHINE CONSISTS OF Straining Unit This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured be reveling the cylinder and ram of any possible side loading by the provision of ball seating. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads, Compression, transverse, bending, shear and hardness tests are conducted between the lower cross head and the table. The lower cross-head can be raised or lowered rapidly by operating the screwed columns thus facilitating ease of fixing of the test specimen Control Panel The control Panel consists of a power pack complete with drive motor and an oil tank, control valves. A pressure transducers is connected for load indicator and a rotary encoder for elongation with resolution of 0.1 mm, is provided to measure the deformation of the specimen Power Pack The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump Provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls Hand operates wheels are used to control the flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken. Load Deflection Indicator It is microprocessor based electronic control panel connected with machine using Pressure Transducer, Rotary Encoder and Electronic Extensometer. Using RS-232 serial communication port our s/w communicates with machine and get real time Load, Deflection and Extension and shows on computer. Electronic digital displays Load Elongation and extension. Facility to hold peak - load and tare facility to make load zero. Elongation display can be set to zero. Optional printer facility. All other facilities maintained under Model UTN. Printer and PC interface. Electronic Control Panel The electronic control panel is built using 8085 microprocessor which incorporates state of the art technology with following features Front panel membrane type key board for test setup. Seven segment digital display of load displacement/extension. Serial Port for communication with PC. Optional add-on facility for electronic extensometer & electronic load pacer. Software Package on PC The control panel can be hooked to any PC using RS-232 communication port. Offers different exhaustive application. Widows based software packages with real time graph On PC to enable the user to effectively evaluated different parameters the features include: NEW Electronic Control Panel Real time graph, user friendly software. Extensive graphics on screen for curve plotting, magnification and zooming. Software Features includes graph comparison, point tracing facility. Different units selection for load & Displacement. Statistical evolution with water fall digs. Mean deviation, frequency distribution, Skew digs Histogram. Also calculates Max. Value, Min. value, Mean Value, variance, Standard deviation. Selectable batch & statistical printouts. Evolution of wide range of user selectable parameters such as % elongation, % reduction in area, young’s modulus, yield stress, proof stress etc. Software packages for shear, Bend, Torsion, Rubber, Tensile testing etc.

Application : Testing

Voltage : 440V

Automatic Grade : Automatic

Warranty : 2 Years

...more

Front Open Universal Testing Machine

1 Piece (MOQ)

FEATURES Loading accuracy as high as ±1%. Straining at variable speeds to suit wide range of materials. Printer & PC graphs enable study the behavior of the material. Motor Driven threaded columns for quick effortless adjustment rapid fixing of test specimen. Simply in reading because of digital readouts. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standard specimens as well as structures. RS 232 serial port to transfer data to computer for analysis/storage evaluation etc. Manual Control & release valve Operation. Safe operation ensured by means of safety devices. APPLICATIONS Universal Testing Machine is designed for testing metals and other materials under Tension, Compression, Bending, Transverse and shear loads. Hardness test on metals can also be conducted ACCURACY & CALIBRATION All Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS: 1828-1975. Universal Testing Machines Comply with grade "A" of BS: 1610: 1964 and grade 1.0 of IS -1828-1975 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the Maximum permissible error is 0.2% of the full reading. PRINCIPLE OF OPERATION Operation of the machine is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The system is ideal since it replaces transmission of load: through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self - lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through leverage to the pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of the specimen. MACHINE CONSISTS OF Straining Unit This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured be reveling the cylinder and ram of any possible side loading by the provision of ball seating. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads, Compression, transverse, bending, shear and hardness tests are conducted between the lower cross head and the table. The lower cross-head can be raised or lowered rapidly by operating the screwed columns thus facilitating ease of fixing of the test specimen Control Panel The control Panel consists of a power pack complete with drive motor and an oil tank, control valves. A pressure transducers is connected for load indicator and a rotary encoder for elongation with resolution of 0.1 mm, is provided to measure the deformation of the specimen Power Pack The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump Provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls Hand operates wheels are used to control the flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken. Load Deflection Indicator It is microprocessor based electronic control panel connected with machine using Pressure Transducer, Rotary Encoder and Electronic Extensometer. Using RS-232 serial communication port our s/w communicates with machine and get real time Load, Deflection and Extension and shows on computer. Electronic digital displays Load Elongation and extension. Facility to hold peak - load and tare facility to make load zero. Elongation display can be set to zero. Optional printer facility. All other facilities maintained under Model UTN. Printer and PC interface. Electronic Control Panel The electronic control panel is built using 8085 microprocessor which incorporates state of the art technology with following features Front panel membrane type key board for test setup. Seven segment digital display of load displacement/extension. Serial Port for communication with PC. Optional add-on facility for electronic extensometer & electronic load pacer. Software Package on PC The control panel can be hooked to any PC using RS-232 communication port. Offers different exhaustive application. Widows based software packages with real time graph On PC to enable the user to effectively evaluated different parameters the features include: NEW Electronic Control Panel Real time graph, user friendly software. Extensive graphics on screen for curve plotting, magnification and zooming. Software Features includes graph comparison, point tracing facility. Different units selection for load & Displacement. Statistical evolution with water fall digs. Mean deviation, frequency distribution, Skew digs Histogram. Also calculates Max. Value, Min. value, Mean Value, variance, Standard deviation. Selectable batch & statistical printouts. Evolution of wide range of user selectable parameters such as % elongation, % reduction in area, young’s modulus, yield stress, proof stress etc. Software packages for shear, Bend, Torsion, Rubber, Tensile testing etc.

Application : Testing

Voltage : 440V

Automatic Grade : Automatic

Warranty : 1 Year

...more

Torsion Testing Machine

1 Piece (MOQ)

FEATURES Torsion Testing Machine is designed for conducting Torsion and Twist on various metal wires, tubes, sheet materials, torque measurement is by pendulum dynamometer system. Torque ranges can be adjusted by Auto Torque Selector. Torque can be applied to specimen by geared motor through gear box. Autographic recorder gives the relation between torque and angle of twist. The accuracy of torque indication is +1% of the true torque.

Automatic Grade : Automatic

...more

Spring Testing Machine

45,000 - 560,000 Per Piece

1 Piece (MOQ)

INTRODUCTION Our range of Spring Testing Machines is widely used for quick and accurate testing of compression & tension test of springs. The machine comprise of two hard chrome plated columns with fine cut single screw with hand wheel for manual loading and unloading arrangement. The machine uses a high precision Load Cell for measurement of force. For displacement measurement Mechanical Linear Scale or Digital Vernier Caliper or Rotary Encoder is used. Measuring System is based on latest microcontroller / microprocessor based electronic panels with all facilities. FEATURES Microprocessor / Microcontroller Based Unit Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick And Accurate Measurement Interchangeable Load Cells Modulus Data For Load & Displacement (For Selectable Models With Software) Optional Dot Matrix Printer Interface Optional Windows Xp Based Software With Rs-232 Interface Simple Controls for Ease of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation With Drive & Motor Available OPTIONS Hydraulic Pump Operated Machine Digital Vernier Scale with 0.01 mm resolution for displacement measurement (6” or 12”) Rotary Encoder with separate digital unit with resolution 0.1 mm or 0.01mm 9 /24 pin Dot Matrix printer interface Serial RS-232 interface with windows

Weight : 100-500kg

Voltage : 440V

Driven Type : Electric

...more

Pendulum Impact Tester (Model - IT30(D) )

1 Piece (MOQ)

The pendulum Impact Tester, Model IT-30 is designed for conducting Izod, Charpy test. The test methods confirm to BS:131:PART 4-1972 (Amended 15 Aug. 1993) BSEN:10045-2:1993. The pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy the lower one for Izod testing. On release, the pendulum swings down to break the specimen & the energy absorbed in doing so is measured as the difference between the height of drop before rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on digital readout in case of electronic machines). There are two strikers and one combined support anvil available for fitting in to the pendulum and on the base of machine for the Izod, Charpy test respectively. Changing from one striker to another is achieved simply by fixing the new striker into it’s position. CHARPY TEST The Charpy test piece rests on alloy steel support anvils, fitted on the base of the machine rigidly held in position by Allen screws. End stopper is provided for quickly and accurately locating the test piece centrally between the supports. IZOD TEST The Izod Test piece is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the test piece in correct height with the help of Izod setting gauge supplied. Optional accessories Self centering tong for quick and accurate setting of Charpy test specimen ‘V’ notch milling cutter. Caliper gauge checking V notch for Izod & Charpy. ‘U’ notch milling cutter. Templates for checking 10x10mm. Cross section of Izod/Charpy test specimen. Depth notch gauge including V & U notch gauges for checking depth below V/U notch, angle and radius. Standard Accessories Izod Striker Charpy Striker Anvil Spanner Set Manual

...more

Pendulum Impact Tester ( Model - IT ASTM )

1 Piece (MOQ)

MODEL : IT ASTM The Impact Tester offered with 300 & 400 J energy exclusively for Charpy test confirming to ASTM E-23. This machine is geometrically checked in the works to the more stringent requirements of the American standard. The accuracy of the machine is then verified by PROOF TEST by testing standard test specimens supplied by the NIST, USA. Two sets (Low & high energy-1 Set (4 Nos.) each.) must agree with the normal values within certain tolerance specified. Standard Accessories Charpy Striker Anvil Spanner Set Manual

...more

Pendulum Impact Tester (Model - IT 30 )

1 Piece (MOQ)

The pendulum Impact Tester, Model IT-30 is designed for conducting Izod, Charpy test. The test methods confirm to BS:131:PART 4-1972 (Amended 15 Aug. 1993) BSEN:10045-2:1993. The pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy the lower one for Izod testing. On release, the pendulum swings down to break the specimen & the energy absorbed in doing so is measured as the difference between the height of drop before rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on digital readout in case of electronic machines). There are two strikers and one combined support anvil available for fitting in to the pendulum and on the base of machine for the Izod, Charpy test respectively. Changing from one striker to another is achieved simply by fixing the new striker into it’s position. CHARPY TEST The Charpy test piece rests on alloy steel support anvils, fitted on the base of the machine rigidly held in position by Allen screws. End stopper is provided for quickly and accurately locating the test piece centrally between the supports. IZOD TEST The Izod Test piece is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the test piece in correct height with the help of Izod setting gauge supplied. Optional accessories Self centering tong for quick and accurate setting of Charpy test specimen ‘V’ notch milling cutter. Caliper gauge checking V notch for Izod & Charpy. ‘U’ notch milling cutter. Templates for checking 10x10mm. Cross section of Izod/Charpy test specimen. Depth notch gauge including V & U notch gauges for checking depth below V/U notch, angle and radius. Standard Accessories Izod Striker Charpy Striker Anvil Spanner Set Manual

...more

Optical Brinell Hardness Tester

196,000 Per Piece

1 Piece (MOQ)

Machine designed with a hydraulic power pack and control circuit for effortless loading unloading operation. A dial gauge in front measure depth of ball penetration. This facilities production testing within tolerance limits by compression method. Basic machine design & operation similar to B 3000 (H). in addition, ‘Optical Device’ with 14 x magnification provided in front of project dia of ball impression on glass screen with a micrometer measuring system with 0.01mm accuracy. The indenter swivels & projects dia of ball impression immediately after unloading operation which avoids additional time for measurement of ball impression.

...more

Notch Broaching Machine

1 Piece (MOQ)

Highly Precision Consistency in all specimen Simple clamping for specimen Tool guide for proper alignment Bottom System for easy operation Notch as per Indian / International Standards

Application : Broaching Machines

Weight : 500-1000kg

Feature : Precise Design

Automatic Grade : Automatic

Driven Type : Electric

Warranty : 2 Years

...more

Mechanical Extensometer

1 Piece (MOQ)

It is essential to measure the elongation of test specimen under load, to have it’s mechanical properties. Our Extensometer, Model EM-1 is intended to serve the above purpose. Construction & Application : This consists of two long knife edges at top, two dial indicators and lower knife edges to actuate the dials. The bards are pressed against the specimen by means of clamp. So that the knife edges bite the specimen to avoid any slip. The upper edges are adjustable to provide different gauge lengths for measurement. As deformation takes place the lower knife edges transfer the movement to the dial gauges and the deformation of specimen is shown on dials, so that the change in length of specimen by 1/100 mm, equals to one division of the graduation on dial.

...more

Manual Brinell Hardness Tester

96,000 Per Piece

1 Piece (MOQ)

Machine designed with a hydraulic power pack and control circuit for effortless loading unloading operation. A dial gauge in front measure depth of ball penetration. This facilities production testing within tolerance limits by compression method. Basic machine design & operation similar to B 3000 (H). in addition, ‘Optical Device’ with 14 x magnification provided in front of project dia of ball impression on glass screen with a micrometer measuring system with 0.01mm accuracy. The indenter swivels & projects dia of ball impression immediately after unloading operation which avoids additional time for measurement of ball impression.

...more

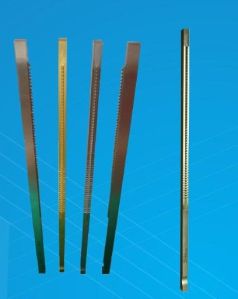

Industrial Broaches

8,600 - 32,000 Per Piece

1 Piece (MOQ)

Thickness : 20-40mm

Application : Industrial Use

Feature : Accuracy, Easy Fitting, Sharp Edge

Surface Finishing : Coated

...more

Hydraulic Brinell Hardness Tester

123,000 Per Piece

1 Piece (MOQ)

Machine designed with a hydraulic power pack and control circuit for effortless loading unloading operation. A dial gauge in front measure depth of ball penetration. This facilities production testing within tolerance limits by compression method. Basic machine design & operation similar to B 3000 (H). in addition, ‘Optical Device’ with 14 x magnification provided in front of project dia of ball impression on glass screen with a micrometer measuring system with 0.01mm accuracy. The indenter swivels & projects dia of ball impression immediately after unloading operation which avoids additional time for measurement of ball impression.

...more

Hardness Testing Machine

1 Piece (MOQ)

ELECTROMECH ENGINERS Hardness Testers Models RAS SE, RABI SE, TWIN SE are Manually operated. All these models are suitable for testing Hardness of metals & alloys of all kinds hard & soft, whether flat, round or irregular in shape Theses testers are simple in design & easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for Engineering colleges, Testing laboratories, Inspection departments, Manufacturing Companies, Research Center etc. These testers strictly conform to IS:1586 – 2000, BS:891 parts 1&2, ASTM: E18 for Rockwell Test, IS:2281-1983, BS:240, ASTM: E10 for Brinell Test & IS: 1586 – 2000, ASTM: E18 for Rockwell Superficial Test

Voltage : 440V

Display Type : Both

Driven Type : Electric

Warranty : 1 Year

Material : Mild Steel

Packaging Type : Carton Box

...more

Fatigue Testing Machine

126,400 Per Piece

1 Piece (MOQ)

APPLICATION & OPERATIONS This machine is used to test the fatigue strength of materials and to draw S-N diagram by research institute, laboratories, material manufacturers and various industries. This is rotating beam type machine in which load is applied in reversed bending fashion. The standard 8mm dia specimen is held in special holders at its ends and located such that it experiences a uniform bending moment. The specimen is rotated at 4200rpm by a motor. A complete cycle of reversed stresses in all fibers of the specimen is produced during each revolution. The bending moment is applied with the lever system and can be easily changed by moving a weight over the lever. Total number of revolution at which the specimen fails are recorded by a mechanical counter. An interlocking system puts off the motor at specimen failure. Machine meets requirement of IS 5075-1969. 6-digit electronic counter instead of mechanical counter can be supplied at additional price. Machine with maximum bending moment up to 400 Kg. cm can be offered on request. FEATURES User Friendly. Test as per IS 5075 Table model, no need of foundation. Simple lever system for changing load Calibration in Nm available on request. Light weight, Simple design, Compact Size.

...more

Erichsen Cupping Testing Machine

42,300 Per Piece

1 Piece (MOQ)

Electromech Engineers Erichsen Tester is designed to carry out Erichsen Cupping Test on metals. Quick clamping and manual operation facilitates faster and trouble-free working of the machine. FEATURES User Friendly. Table model, no need of foundation. Simple lever system for changing load Light weight, Simple design, Compact Size.

...more

Electronic Extensometer

96,000 Per Piece

1 Piece (MOQ)

The Electronic Extensometer, Model EE-2 is manufactured as per IS:12872:1990 & ISO 9513:1989 in class 1 accuracy. This equipment is basically used with Universal Testing Machines for Tension Test. It is used for measuring young’s modules, proof stress or yield stress. Ee2 Extensometer requires electronic signal conditioning PCB to interface it with UTM electronic panel. Optional Accessories EE-2 with gauge length 25.4, 62.5,70 & 80 mm Specimen thickness or dia 4 to 40 mm & 4 to 50 mm.

...more

Digital Torsion Testing Machine

1 Piece (MOQ)

FEATURES Torsion Testing Machine is designed for conducting torsion and twist on various metal wires, tubes, sheet materials. Torque measurement is by torque transducer system. Torque can be applied to specimen by geared motor through gear box. Autographic recorder gives the relation between torque and angle of twist. The accuracy of torque indication is + 1% of the true torque. The electronic control panel is built using 8085 microprocessor which incorporates state of the art technology with following features – Front panel membrane type key board for test setup. 7 seg digital display of load displacement/extension. Printer port interface. Serial port for communication with PC. Storage of important parameters such as peak load & maximum displacement after test. Preload selection to take care of initial slippage. Optional real time graph & PC software.

Weight : 100-500kg

Voltage : 380V

Driven Type : Electric

...more

Computerized Vickers Hardness Tester

1 Piece (MOQ)

Wide Testing Range from Soft metal to medium hardness Steel. Motorized loading/unloading. High Accuracy & Repeatability of measurement at all loads. Features : Computerized (PC based) Vickers Hardness Machine. Direct & accurate measurement of Vickers hardness number using "State of the art" image processing technology. Wide testing range: from soft metal up to hardest. High accuracy & repeatability of measurement at all loads. Faster measurement yielding to higher productivity. Small size of indentation makes it a non destructive testing on finished components. Motorized loading and unloading cycle. Small loads allow testing on thin sheet metals.

...more

Brinell Image Analysis System

38,000 Per Piece

1 Piece (MOQ)

It is found that measuring Brinell indentations can result in measurement errors between operators. This B.I.A.S. can virtually eliminate operator influence on test result. - The B.I.A.S virtually eliminates operator influence With this handy instrument entire test sequence is simple. Place the scan hand on the work piece on 'Auto' in tool bar on computer screen. The B.I.A.S. automatically measures the diameter of indentation with resolution of 0.01mm and display Brinell value with diameter measurement. All data storage functions are automatically performed according to batch parameters. - Just place and click! Operating B.I.A.S is easy An unlimited number of batches can be created each with its own test parameters and certificates. The operator can select test load and indenter size with arty name, address, certificate no. date batch no. and description, high and low limits for readings etc. The previous batches can be reopened for viewing and address change etc. - The B.I.A.S. can be configured to meet your needs The B.I.A.S. has built in statistical capabilities with graph and certificate for report generation and printing. It includes frequency distribution and variation graphs. The systems includes calibration and check facilities to calibrate the systems and for checking of calibration. This eliminates any systems error in measurement. THE SOFTWARE Facility for Auto / semi Auto / Manual modes of operation. Well managed database saves readings with respect to batch and certificate. Report generation in the form of certificate and graph as per customer requirements. Facility for calibration and check of calibration. Specification: The range of Measurement is from 1mm to 6 mm of diameter with Resolution of 0.01mm. Applications: To measure Brinell Hardness directly on machine where presently Brinell-Microscope is used. This avoids eye straining of operator on producing testing. In addition, it gives far better repeated accuracy. High-low limits selections enables operator easy acceptance / rejection of components. Easy to transport anywhere and handy for use with easy setup.

Application : Medical Use

Warranty : 1yr

Automation Grade : Manual

...more

hardness dial

1,900 Per Nos

Microscope

3,500 Per no

Opening Hours