VICKY'S Computerised Vickers Hardness Tester

Features : • Fully Computerised (PC Based) Vickers Hardness Machine.• Direct and accurate measurement of Vickers Hardness number using "State of the Art" image processing technology.• Wide testing range : from soft metal up to hardest.• High accuracy and repeatability of measurement at all loads.• Faster measurement yielding to higher productivity.• Small size of indentation makes it a non destructive testing on finished components.• Motorised loading and unloading cycle.• Small loads allow testing of thin sheet metals. • Advanced Window XP based software : Latest GUI Features : • User friendly software with Windows Features.• Online indentation setting and focusing on PC monitor.• Advance image processing : Algorithms implemented for precise calculation of hardness numbers with various options to cover all ranges of specimen. Batch file Processing : Option for Data, storage and reports generation. Statistical Evaluation : Software forcalculating standard deviation, mean, medium, histogram etc. • Wide options in calibration mode.- Calibration / Verification on PC monitor makes easier to operate. 'FIE' Computerised Hardness Tester is a simple and accurate means to produce automatically measure the diamond indentation to give Vickers hardness numbers. • Intel Pentium IV 2.00 GHz or above processor is recommended. • Microsoft Windows 98SE or above (Recommended XP)• System Ram : 128 MB or above (Recommended 256 MB)• One RS 232 (serial) port. (PC not included in standard scope of supply) These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard and their accurate results are widely acclaimed. These testers strictly confirm to IS 1754 - 2002.

...more

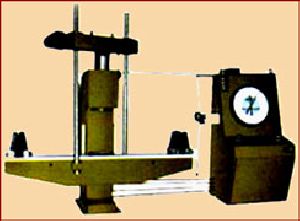

Vickers Hardness Testing Machine

The robust machine frame is designed to accommodate the high precision loading system and an optical projection screen.Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond penetrator by means of a lever and weights. After a specific lapse of time, the load is removed automatically.Testing range is very wide, from soft metal such as lead, upto the hardest, like hardeness steel.

...more

Vickers hardness testing

Vickers Hardness Tester is a simple and accurate means to produce and measure the diamond indentation. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range from soft to hard and their accurate results are widely acclaimed. Testing range is very wide, from soft metal such as lead, upto the hardest, like hardened steel.

...more

Vickers Hardness Tester

Testing range is very wide, from soft metal such as lead, upto the hardest, like hardeness steel.Same hardness number is obtained on the same specimen, regardless of the load applied.Thin sheet metal is perfectly tested because the load applied is very small.'FIE' Vickers Hardness Tester is a simple and accurate means to produce and measure the diamond indentation.

...more

Vertical Balancing Machine

Machines Model HDVTm are Vertical type single plane hard bearing Balancing machine provided with Microprocessor based measuring panel HDVM-8500 for balancing Disc shaped rotors such as Clutch plates.

...more

Universal Testing Machines

• Loading accuracy as high as + 1%.• Straining at variable speeds to suit a wide range of materials.• Printer & PC graphs enable study the behavior of the materials.• Motor driven threaded columns for quick effortless adjustment of middle crosshead to facilitate rapid fixing of test specimen.• Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials• Simplicity in reading because of digital readouts.• Wide range of standard and special accessories, including load stabilizer.• Easy change from plain to threaded and screwed specimens.• Large effective clearance between columns enables testing of standard specimens as well as structures.• Simple controls for easy of operation.• Robust straining frame of an extremely rigid construction.• Safe operation ensured be means of safety devices.• Fully enclosed and protected pressure transducer. • RS 232 serial port to transfer data to computer for analysis/storage evaluation etc. • Manual control & release valve operation. Application : FIE Electronic Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also conducted. 0 Principal of Operation : Operation of the machine is by hydraulic transmission of load from the test specimen through pressure transducer to a separately house load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the pressure transducer housed in the control panel. The transducer gives the signal to the electronic display unit corresponding to the load exerted by the main ram.Simultaneously the digital electronic fitted on the straining unit gives the mechanical displacement to the electronic display unit. Both the signals are processed by the microprocessor and load and displacement is displayed on the digital readouts simultaneously.

...more

Universal Tensile Testing Machine

Electronic Universal Testing Machines - Model : UTE Features : Loading accuracy as high as + 1%. Straining at variable speeds to suit a wide range of materials. Printer & PC graphs enable study the behavior of the materials. Motor driven threaded columns for quick effortless adjustment of middle crosshead to facilitate rapid fixing of test specimen. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Simplicity in reading because of digital readouts. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standard specimens as well as structures. Simple controls for easy of operation. Robust straining frame of an extremely rigid construction. Safe operation ensured be means of safety devices.

...more

Stainless Steel Clamps

Our Company offers high quality Stainless Steel Clamps which are manufactured, using superior quality raw material SS 304, procured, from the reliable and reputed vendors of the industry. S.S. Clamps are available in various sizes as per the customers specifications.

...more

Spring Load Testing Machine

Operation of the machine is by hydraulic transmission of load from the test specimen through pressure transducer to a separately house load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage.

...more

Saroj Make Rockwell Hardness Testing Machine

Features : Rockwell, Rockwell Brinell Combined, Rockwell/Rockwell Superficial Combined System Hardness Testers. SAROJ Hardness Testers, Model RAS, RAB-1, RAB-250, TWIN are manually operated. All these models are suitable for testing hardness of metals sand alloys of all kinds hard or soft, whether flat, round, or irregular shape. These testers are simple in design and easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for schools, laboratories, tool-rooms, inspection, heat treatment departments, factories etc.These testers strictly confirms to IS : 1586-2000, ASTM : E 18 for Rockwell Superficial Test and IS : 2281 -2005, ASTM : E 10 for Brinell test. Model RAS : Model RAB-1 Model TWIN Automatic load selection with automatic zero setting dial gauge. Automatic load selection & automatic zero setting dial gauge. Facility for Brinell tests with 187.5 kgf. load with 2.5 mm Ball indicator, additional load 250 kgf. with 5mm Ball indentor for testing hardness of non- ferrous metals. Automatic load selection with automatic zero setting dial gauge. Manual operation. Manual operation. Diamond holder is guided in a ball cage, which enables testing of small pins having dia. Less than 6 mm (up to 3mm dia.) Model RASM (Motorised) : Model RAB 250 Similar to 'RAS' but motorised model. Semiautomatic operation for production testing. Drive motor single phase 230 V 50 Cycles. Similar to 'RAB-1' but of bigger capacity. Diamond holder is guided in a ball cage, which enables testing of small pins having dia less than 6 mm ( up to 3 mm dia.)

...more

Rockwell Hardness Testing Machines

Principal : Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value.Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell hardness number. Operation : For Rockwell & Rockwell Superficial Test : In case of 'RASN' series machines for Rockwell & Rockwell superficial tests a preliminary test force in first applied and then indicator is automatically set for zero. Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator. For Brinell Test : The operation is exactly same as above. However, the diameter of impression is measured outside of machine by Brinell microscope. Brinell hardness number is found out by referring corresponding hardness tables showing hardness number against dia. of indentation for specified ball diameter and test force. • Suitable for Rockwell Tests.• Manually Operated.• Preliminary Test Force - 98.07 N (10kgf).• Additional Test Force - 490.3, 882.6, 1373N (50.90, 140 kgf).• Total Test Force - 588.4, 980.7, 1471N (60, 100, 150 kgf).• Test Force Selection by external dialing.• Auto zero setting dial gauge.Rockwell cum Brinell Tester, Model RASN (B)• Same as RASN above in additional• Additional Test Force - 1471, 2354N (177.5, 240 kgf) • Total Test Force - 1839, 2452N (187.5, 250 kgf)

...more

Rockwell Hardness Tester

Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. Test Force Selection by external dialing.

...more

Rockwell Cum Rockwell Superficial Hardness Tester

• Suitable for Rockwell & Rockwell Superficial Tests.• Manually Operated.• Preliminary Test Force - 29.42, 98.07N (3, 10kgf).• Additional Test Force - 177.7, 264.8, 411.9, 490.3, 882.6, 1373N (12, 27, 42, 50, 90 & 140 kgf).• Total Test Force - 147.1, 294.2, 441.3, 588.4, 980.7, 1471N (15, 30, 45, 60,100,150 kgf).• Test Force Selection by external dialing.• Auto zero setting dial gauge. FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes. 1) The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. 2) The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. 3) A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. 4) An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. 5) All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. 6) All four models confirm to respective standard as under. IS : 3804, BS 10109-2 & ASTM E-18 for Rockwell Test. IS : 5073, BS 10189-2 & ASTM E-18 for Rockwell Superficial Test. IS : 2281, BS 10003-2 & ASTM E-10 for Brinell Test.

...more

Real Time Graph Electro-Mechanical Universal Testing Machines

Electro Mechanical Universal Testing Machines UNITEK 9700 Series with Interface & Real Time Graph ( Panel / PC Controlled ) Electro Mechanical Universal Testing Machines UNITEK 9700 Series with Interface & Real Time Graph ( Panel / PC Controlled ) Technical Description : FIE Universal Testing Series Unitek 9700 are microprocessor based Electromechanical machines with Servo drive designed for testing & Studying mechanical behavior of various materials like metals, polymers Etc. These machines offer good built-in features to offer excellent stand alone performance for standard tests & great flexibility for complex analysis. These machines confirm to IS, BS & ASTM standards. Main Features : • Precision DC Servo motor & drive with ball lead screw gives an advanced drive system with 1 to 1000 standard speed range. • Computerised Microprocessor based instrumentation to measure display & store load & displacement value. • Provision for load cell interchangeability & thereby automatic selection of load full scale. • Speed selection through Data entry or variable speed selector through potentiometer. • Facility for mounting different load cells & clamping devices to suit different tests & materials such as thin wires, metalsheets, fiberglass, leathers, springs, cardboards etc. • Built-in parallel interface to connect printer for data & curve print-out. • Safety interlock for overload & limit switch sensing to ensure protection during test. • Universal applications in R & D, education, quality control & production for test like tensile, compression, bending etc. Electronic Control Panel : (Series Universal 2001) • Microprocessor based panel incorporating state of art technology with following features. • Front Panel membrane type key board for machine operation with numeric keys for data entry. • 7segment display. • Auto load cell identification. • Data entry with numeric keyboard of test parameters including speeds, rupture % peak, preload, modulus data , test data & specimen data etc. • 20input data set storage, 50 results storage, maintains data & results during power off. • Batch test facility for generating batch & statistics result using same data set. • optional remote to ease specimen loading/unloading. • RS 232C serial port, Optional windows based software available for..... • On line graph on PC. Data analysis, statistics, point tracing superimposing graphs to compare with standard, zooming graph etc. Printer port for printer interface with ..... • Graph & result printout. • Test certificate printout.• Batch certificate printout. • Simple statistic printout. Optional Accessories : FIE offers a wide range of optional accessories along with unitek 9700 Machines to cover almost every material test requirement. Load Cells : FIE offers Strain gauge type Universal load cells in different capacities in the following nominal ranges : 100N, 250N, 1kN, 2.5kN. Load cells of different capacity can be offered as per customers requirements. Grip & Clamping Devices : A wide range of grips are available from FIE such as : • Vise type grips.• Single threaded grips. • Compression Plates. • Bending Fixtures. • Shearing Attachments. Extenso meters : Electronic analog extensometers are offered along with interface card on the control panel to measure with a resolution of 1 micron. • Model : EE2-STRAIN GAUGE • Serial Communication & Software Package on PC The Universal 2001 series control panel can be hooked to any PC using RS-232 communication port. FIE offers different windows based software packages with real time graph on PC to enable the user to effectively evaluate different parameters. The features include : • Real time graph, User friendly software.• Extensive graphics on screen for curve plotting, magnification and zooming. • Software features includes Graph comparison, point tracing facility. Different units selection for load & displacement. • Statistical evaluation with water fall dig., Mean deviation, frequency distribution, Skew dig., Historigram. Also calculates max. value, min. value, mean value, Variance, Standard Deviation.(Other statistical parameters on request). Selectable batch & statistical printouts. • Evaluation of wide range of user selectable parameters such as % elongation, % reduction in area, young's modulus, yield stress, proof stress etc. • Software packages for Shear, Bend, Torsion, Rubber, Textile etc. • Custom built application software to suit customer requirements.

...more

Portable Hardness Tester

'DT' Portable Rockwell Hardness Tester is developed to meet the demands of a light weight instrument which can be used to carry out tests by a universally recognised method of Hardness testing. The machine is designed for carrying out Rockwell tests comparable to table model hardness tester because, the basic things, such as shape of penetrator, method of penetration, measurement and loads are same in both systems.

...more

Pendulum Impact Testing Machine

The Pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy & the lower one for Izod testing. On release, the pendulum swings down to brake the specimen and the energy absorbed in doing so is measured as the difference between the height of drop before rupture of the test specimen and is read from the maximum pointer position on the dial scale.

...more

micro vickers hardness testing machine

'FIE' Computerised Microvickers Hardness Tester is a simple and accurate means to produce and automatically measure the diamond indentation to give micro hardness numbers directly. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS:1754:2002 and ISO 6507-2:1997.

...more

Micro Hardness Tester

The machine frame is designed to accommodate the high precision loading system. Specimen is clamped by vice or supported by proper fixtures. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of dead weights. After a lapse of time, the load is removed automatically. The image id digitallized using a CCD Camera fitted on the machine and is captured by the PC. The diagonals of the indentation are measured by the PC and the Micro Hardness number is displayed directly on monitor. Batch File Processing : Option for data storage and reports generation for case depth analysis etc. Direct and accurate measurement of micro hardness number using "State of the art" image processing technology. Statistical Evaluation : Software for calculating standard deviation, mean, medium, frequency distribution graph, variation graph etc.

...more

Mechanical Universal Testing Machines

FIE introduces its new model of Universal Testing Machine with design flexibility, a modern appearance and high performance electronics. Some of the features include - Features : • Open type crosshead. • Hydraulic wedge action grips.• Load cell technology.• Long test stroke and test space.• Straining at variable speeds to suit a wide range of materials.• Touch screen Control Panel Black and White or colour with printing & computer connectivity.• Tension, Compression and Transverse test facility.

...more

Mechanical Universal Testing Machine

Loading Accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for easy of operation. Robust staining frame of an extremely rigid construction. Safe operation ensured be means of safety devices. Fully enclosed and protected pendulum.

...more

Mechanical Extensometer

It is essential to measure the elongation of test specimen under load, to have it's mechanical properties. FIE Extensometer Model EM-1 is intended to serve the above purpose. So that the knife edges bite the specimen to avoid any slip. The upper edges are adjustable to provide different guages lengths for measurement.

...more

Material Testing Machines

Material Testing Equipment

With the complete help and support of our team members, we deliver product that is certified and in compliance with the standards. Notable name in this field, we successfully cater to the demands of our clientele from Maharashtra(India) to every nook and corner.

...more

Laminated Spring Testing Machine

The FIE Spring Testing Machine, Models St and CST, incorporates design features to enable high accuracy testing with economy, speed and versatility • Loading Accuracy as high as + 1%• Four standard measuring ranges available with auto load-selector.• Deflection is read directly on electronic Electronic Digital Display.• Straining at variable speeds to suit a wide range of applications.• Autographic recorder supplied as standard to enable study of behavior of springs • Motorised drive for rapid adjustment of the height • High reading accuracy due to large size of dial.• Large effective test space enables testing of wide range of springs.• Robust staining frame of an extremely rigid construction.• Safe operation ensured be means of safety devices.• Fully enclosed and protected pendulum. Application : FIE Laminated Spring Testing Machine is designed to test Laminated Springs and Coil Springs under compression and bending loads. Principal of Operation : Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces.Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen.Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen. Machine consists of : Straining Unit : This consists of a "C" type rigid frame with hydraulic cylinder at its top and adjustable main testing tale is connected to an upper cross-head through two screwed columns can be rapidly adjusted to test height by means of motor. A pair of trolleys is provided on the table to take the horizontal deflection of the spring under loading. Laminated springs are tested by placing them on trolleys provided on the table. Coil Springs are tested by placing them between the compression plates. Hardness test can also be conducted with a suitable attachment. Control Panel : The control Panel consists of a power pack complete with drive motor and an oil tank, control valve a pendulum dynamometer a load and deflection indicating system and an autographic recorder. Power Pack : The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls : Hand operated wheels are used to control the flow to and from the hydraulic cylinder. The regulation in the oil is infinitely variable. Incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of table movement. Load and Deflection Indicator System : The load Indicator System consists of a large dial and a pointer. A dummy pointer is provided to register the maximum load reached during the test. Different measuring ranges can be selected by operating the range selection knob. An overload trip switch is incorporated which automatically cuts out the pump motor when the load range in use is exceeded.The deflection indicator system operates electronically and deflection is read directly on the digital display with least count of 0.1 mm. The encoder is mechanically coupled to the main hydraulic ram for getting signal of deflection. Pendulum Dynamometer : This unit permits selection of favorable hydraulic ratios producing relatively small frictional forces. Pressurised oil in the loading cylinder pushes up the measuring piston proportionately and actuates the special dynamometer system. The piston is constantly rotated to eliminate friction. The dynamometer system is also provided with special damper and ensures high reliability of operation. The load transmitted to the dynamometer is transferred through a pendulum to the load indicator. Autographic Elongation Recorder : This unit is of the pen and drum type and is supplied as standard. The horizontal motion of the pen produces the load ordinate of the diagram and the drum rotation produces the extension ordinates in the ratio of either 1:1 or 1:2. Accuracy & Calibration : AII FIE Laminated Spring Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in BS : 1610 : 1964FIE Spring Testing Machines comply with Grade "A" of BS : 1610 : 1964 and Grade 1.0 of IS 1828 : 1975 An accuracy of + 1.0% is guaranteed from 20% of the load range selected to full load. Helical Coil Spring Testing Machine Model CST : FIE's range also includes Helical Coil Spring Testing Machine, Model CST for testing coil springs under compression loads. the principle of operation, details on control panel, except deflection indicator system, accuracy and calibration are the same as the laminated Spring Testing Machine. Model ST described alongside. The straining unit is designed for coil Springs. It consists of a Hydraulic Cylinder and a table coupled with the ram of the hydraulic cylinder mounted on a robust base. The cylinder and the ram are individually lapped to eliminated friction. The cross-head is connected to two screwed columns and is driven by a motor for rapid adjustment of test height.

...more

Dynamic Balancing Machine

These machines features a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, measures and stores the unbalance values on DPMs for two planes simultaneously and stops machine ( with brake if machine is provided with electrical breaking facility.) The measuring cycle general is less than 10 seconds for normal rotors, which can be accelerated within 5 seconds.

...more

Dynamic Balancing

The machines features a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, Measures and stores the unbalance values on DPMs for two Plane simultaneously and stops machine. Key board facility provided in measuring panel for correct data deeding of rotor with l digit accuracy for its dimensions like A.B. C, R1 & R2. Tolerance limits of both correction planes i.e.t 11 & t12 can be feed so that when rotor is balanced within the limits respective LEDs glow up, indicating no further correction necessary. For other details please refer “ features of measuring panel HDCM-8500", These machines are very simple in design. No. drive coupling adaptor etc.

...moreBe first to Rate

Rate ThisOpening Hours