Vibratory Feeder Machine

Get Price Quote

Industrial Tensile Testing Machine

163,000 Per piece

1 piece (MOQ)

We are offering the high-quality collection of Industrial Tensile Testing Machine to our valuable customers. Our offered products are made with following set industry standards under the direction of experts. These are used for conducting tensile & compression test on wires, tubes, sheet material, cables, conductors, leather, asbestos paper, and much more.

Best Deals from Industrial Machine

rotary transfer special purpose machine

2,300,000 Per Piece

Shrink Tunnel Machine

Get Price Quote

01 Piece(s) (MOQ)

Shrink tunnel adopts hot-wind down-cyclone structure, intelligence temperature control and PMDC variable speed regulation. There are two optional conveyors, including Teflon belt type and roller type. Variable Speed, Low Power Consumption, Efficient Heating Chamber.

Board Cutting Machine

Get Price Quote

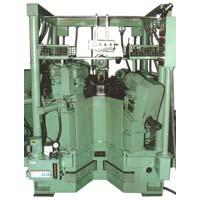

rotary transfer machines

Get Price Quote

Rotary transfer SPM’S are useful & economical for mass production of automobile components, agriculture components, & components required for Petro-Chemical industry in mass quantity. Drilling, tapping, boring, milling, operation are done on the rotary transfer SPM. Machine can be build in 4 station, 6 station, 8 station & 12 station type depending upon the requirement of No. of operations to be done. All the operations are carried out at the same time simultaneously. Loading & unloading of the job can be perform while running the machine, hence loading & unloading time required in Rotary transfer SPM is nil & Cycle time required is reduces.

HYDRAULIC LEATHER SHAVING MACHINE

Get Price Quote

INTRODUCTION : Bharat Udyog is manufacturing the Shaving machines in the working widths of 500 mm to 1500 mm. After studying carefully the requirements of the various tanners Bharat Udyog has developed BUKE 1000 mm Shaving Machine for shaving of all types leathers in wet, dry and also blue chrome condition. Its simplicity of operation with extremely rigid construction enables the machine to give high production output with desired quality levels. Decades of experience backed by sound technology and prompt after sales service ensures trouble-free operation and highly productive machine with superior performance, quality and longer life. SALIENT FEATURES : MACHINE CONSTRUCTION : The complete frame structure of the machine is made of graded cast iron with sufficiently thick and well ribbed section. This assures extreme rigidly of construction which eliminates any chance of vibration mark on leather even under heaviest cut. KNIFE CYLINDER : The Knife Cylinder is made from high strength forged steel and rotates in a heavy duty ball bearings with grease lubrication and dynamically balanced to ensure chatter free operation. The standard cylinder is fitted with 10 LH and 10 RH blades. FEED ROLLER : The feed roller is driven by a hydraulic motor with reduction gear box and feed speed can vary from 0 to 20 meters/min. The opening and closing of feed roller is accomplished by precision cam operated mechanism driven by hydraulic cylinder which enables accurate leather thickness even under heaviest cut load. All the links and mechanisms involved are having ball bearings / roller bearings at the joints ensuring friction free movements reducing wear & tear resulting in prolonged machine life.b) Due to the flywheel effect of the main shaft at high speed, the power required is less than equivalent machines. This leads to low power consumption at the same output. GRIP ROLLER : The facility of grip roller enables easy feeding of leather and avoid'wastage of leathers because of cutting at folds. Also it reduces the operator fatigue to a great extent resulting in more output. The machine is provided with taper setting attachment to take care of any uneven thickness after shaving the leathers to its full span. ELECTRONIC FINE THICKNESS ADJUSTMENTS DEVICE : The machine is fitted an electronic fine thickness adjustments device which enables the initial, setting to be varied in steps of 0.1 mm. GRINDING MECHANISM FOR KNIVES : The grinder travels on a heavy duty slide with an electromechanical drive. This enables perfect grinding of knives. The feeding of grinding wheel in knives is automatic and no human intervention is required, reducing time required for grinding. SAFETY : All electric motors are provided with overload relays. Grinding feed can not start until the grinding motor is ON. A safety device is provided near the Knife Cylinder which will stop the machine if the operator touches the same accidently. Sheet metal guards are provided whenever necessary.

Rotary Ironing Machines

Get Price Quote

bi axial rotomoulding machine

Get Price Quote

we are renowned for offering the premium bi-axial rotomoulding machine. our bi-axial rotomoulding machine is precision engineered to offer high efficiency. our bi-axial rotomoulding machine is used in the manufacturing of many items in different industries. we offer these bi-axial rotomoulding machine as per the international standards for quality. bi-axial machine control panel : a.c. variable speed drive for major and minor axis for all armsuser-friendly inexpensive drive system capability to monitor each operation while doling out with auto and semi auto programmable process control systemsafety and alarm strategy provided for burners provided required inter locking system for affecting arms, oven and doors remote control panel for controlling process parameter and monitor the method technical specifications : biaxial machine is fully prepared with the following outstanding featuresdesign of biaxial machine made-up from mild steel which is sturdy reliable designdesign of biaxial machine made-up from mild steel which is sturdy reliable designchoice of three arm and four arm optionschoice of carry type machineschoice of fix oven or portable ovenoptions of straight-arm, offset arm, four mould carrier armsreverse / forward machinery for correct positioning of stationsheating oven with stipulation of two side doorsstraight arm with two roomy spiders to put up different size moulds for expedient workingstraight arm with unique four-mould carrier base plats to utilize the maximum oven space in order to put up four moulds for inexpensive working with zero refusaloffset arm with enough balancing weights for large size moulds and contented functioning designinspection windows to observe the mould rotation and polymer melting situation without opening the oven doorsstipulation for extra second and third layer charging manholes on the top of oven panel without opening the oven doorenergy competent world-class environment welcoming italian burners for lpg/oil and duel fuelefficient hot air scheming blower fans for fast heating of the moulds, implementing state. of the art knowledge and achieving unique wadding design with new generation energy economy insulation material for better working situationsolid oven design and oven shape for finest oven volume and reasonable working with less fuel utilizationexclusive blower design for capable air movementelective cooling station with high efficient air conniving fan or with water mist and water cover process of machine : load the powder foam polymer resin (material) in the mould, which mounted on the armsthe mounted mould arm goes inside the oven and heat started and circulating by blower the polymer resin start meltingthe melted resin sticks in all side of mouldwhen process completed, arm move to the cooling area and cooling process startswhen process completed, arm move to the cooling area and cooling process startswhen mould becomes cool the melted polymer resin convert into solid foam and shrinkafter completion of process, open the mould and take out finished product control : machine operated by control panelthere is a.c. variable speed for major and minor axis of the armsprovided limits for the oven and door while forward/reverse and open/close respectivelyinter locking system available for moving arm, door and ovenautomatic on/off system available for the burner to maintain required temperature

Bag Filling Machine

Get Price Quote

Bag Filling Machine, Bag Handling System, bag stitching machine

compact cnc machines

Get Price Quote

compact cnc machines, CNC Machine, leadwell cnc machines

woven sack tape plant

Get Price Quote

woven sack tape plant, Woven Bed Covers, Woven Interlining

Food Packaging Machineries

Get Price Quote

Food Packaging Machineries, bakery machine, Food Processing Machinery

Chemical Process Equipment

Get Price Quote

Chemical Process Equipment, Engineering machines

Hydraulic Paper Plate Making Machine

Get Price Quote

Hydraulic Paper Plate Making Machine

Industrial Universal Testing Machines

Get Price Quote

Industrial Universal Testing Machines, Torsion Testing Machine - Mech.CS.TT

sub assemblies for printing machine

Get Price Quote

sub assemblies for printing machine, oil engine, Textile Machine

Industrial Equipment

Get Price Quote

Industrial Equipment, three phase solid state relay, d ac contactor

CNC THERMOCOL PATTERN MAKING MACHINE

Get Price Quote

CNC THERMOCOL PATTERN MAKING MACHINE

Paper Plates Making Machines

Get Price Quote

Paper Plates Making Machines, lamination cutting machine

tube end facing machines

Get Price Quote

tube end facing machines, Four Spindle Drilling Cum Reaming Unit For Yoke

Battery Grid Casting Machine

Get Price Quote

Battery Grid Casting Machine

cylindrical gas filled

Get Price Quote

cylindrical gas filled, Power Factor Controller, AC Capacitors

Industrial Washing Machine

Get Price Quote

Storage Racks, Manipulators, Material Storage, Material Handling Equipments