Board Cutting Machine

Get Price Quote

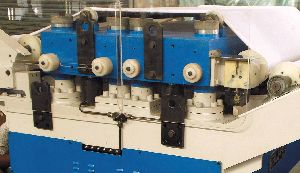

THROUGHFEED STACKING MACHINE

Get Price Quote

INTRODUCTION : The new BUKE Through Feed Staking machines are designed to meet the requirements of the present tanning industry, the machine are suitable for staking of all types of leather. MACHINE CONSTRUCTION : The frame unit is extremely rigid & single piece fabricated structure which can take the load of heavy staking operation. STAKING EFFECT The Machines are designed to give better staking effect on the all the parts of leather from belly to butt.

Best Deals from Industrial Machine

Rotary Ironing Machines

Get Price Quote

bi axial rotomoulding machine

Get Price Quote

we are renowned for offering the premium bi-axial rotomoulding machine. our bi-axial rotomoulding machine is precision engineered to offer high efficiency. our bi-axial rotomoulding machine is used in the manufacturing of many items in different industries. we offer these bi-axial rotomoulding machine as per the international standards for quality. bi-axial machine control panel : a.c. variable speed drive for major and minor axis for all armsuser-friendly inexpensive drive system capability to monitor each operation while doling out with auto and semi auto programmable process control systemsafety and alarm strategy provided for burners provided required inter locking system for affecting arms, oven and doors remote control panel for controlling process parameter and monitor the method technical specifications : biaxial machine is fully prepared with the following outstanding featuresdesign of biaxial machine made-up from mild steel which is sturdy reliable designdesign of biaxial machine made-up from mild steel which is sturdy reliable designchoice of three arm and four arm optionschoice of carry type machineschoice of fix oven or portable ovenoptions of straight-arm, offset arm, four mould carrier armsreverse / forward machinery for correct positioning of stationsheating oven with stipulation of two side doorsstraight arm with two roomy spiders to put up different size moulds for expedient workingstraight arm with unique four-mould carrier base plats to utilize the maximum oven space in order to put up four moulds for inexpensive working with zero refusaloffset arm with enough balancing weights for large size moulds and contented functioning designinspection windows to observe the mould rotation and polymer melting situation without opening the oven doorsstipulation for extra second and third layer charging manholes on the top of oven panel without opening the oven doorenergy competent world-class environment welcoming italian burners for lpg/oil and duel fuelefficient hot air scheming blower fans for fast heating of the moulds, implementing state. of the art knowledge and achieving unique wadding design with new generation energy economy insulation material for better working situationsolid oven design and oven shape for finest oven volume and reasonable working with less fuel utilizationexclusive blower design for capable air movementelective cooling station with high efficient air conniving fan or with water mist and water cover process of machine : load the powder foam polymer resin (material) in the mould, which mounted on the armsthe mounted mould arm goes inside the oven and heat started and circulating by blower the polymer resin start meltingthe melted resin sticks in all side of mouldwhen process completed, arm move to the cooling area and cooling process startswhen process completed, arm move to the cooling area and cooling process startswhen mould becomes cool the melted polymer resin convert into solid foam and shrinkafter completion of process, open the mould and take out finished product control : machine operated by control panelthere is a.c. variable speed for major and minor axis of the armsprovided limits for the oven and door while forward/reverse and open/close respectivelyinter locking system available for moving arm, door and ovenautomatic on/off system available for the burner to maintain required temperature

Borewell Line Machine

Get Price Quote

Borewell Line Machine

Bag Filling Machine

Get Price Quote

Bag Handling System, bag stitching machine, Bagging Machine

tube end facing machines

Get Price Quote

tube end facing machines, Four Spindle Drilling Cum Reaming Unit For Yoke

machine automation

Get Price Quote

machine automation, Generator, Truck, Cnc Plasma Profile Cutting Machine

Vertical Cylinder Honing Machine

Get Price Quote

Vertical Cylinder Honing Machine

sub assemblies for printing machine

Get Price Quote

sub assemblies for printing machine, oil engine, Textile Machine

CNC THERMOCOL PATTERN MAKING MACHINE

Get Price Quote

CNC THERMOCOL PATTERN MAKING MACHINE

cylindrical gas filled

Get Price Quote

cylindrical gas filled, AC Capacitors