Mech CS VM50 Vickers Testing Machine

Mechatronic Control System’s Vickers Hardness Tester is simple & accurate in design. It is suitable for measuring the hardness of precision metallic parts with wide testing range from soft to hard & their accurate results are widely acclaimed. These testers strictly conform to 15:1754-1968. Features Tiny indentation allows testing of a precision finished parts. Thin sheet metal are perfectly tested. Because applied load is very small. Motorized loading and unloading cycle. Built-in projection screen to get accurate results. Same hardness number is obtained on the same specimen, regardless of the load applied. Wide testing range, from soft metal such as lead, Upto the hardest, like hardened steel. Example Applied objective with 70x magnification Length of diagonal of indentation 742 micron = 0.742 Technical Data Test Loads 5,10,20,30,50kg. Magnification of optical projection 70X Max. Test Height (mm.) 200 Scale least count(mm.) 0.001 Depth of throat (mm. 133 Dimensions of Machine (mm.) L585xW290xH860 Weight (Approx) 73kg. Power Supply 220V AC, 50 Hz, 1-Phase Standard Accessories 01 Standard Test Block 1 pc. 02 Diamond Penetrator 1 pc. 03 Weights 1 set. 04 Flat Anvil 1 pc. 05 Vee-type Anvil (Small and Big) 1 pc. each 06 Spanners 1 pc. 07 Electric cord 1 pc. 08 Instruction Manual 1 book Construction To accommodate the high precision loading system & an optical projection screen, the machine frame is designed sturdy. Specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied on a diamond penetrator by means of a lever & weights. The load is removed automatically after a specific lapse of time. The objective is indexed with the test piece & the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

...more

Computerised - VM 50 Vickers Testing Machine

Features Fully Computerised (PC Based) Vickers Hardness Machine. Direct and accurate measurement of Vickers Hardness Number using "State of Art" image processing technology. High accuracy and repeatability of measurement at all loads. Faster measurement yielding to higher productivity. Motorised loading and unloading cycle. Small loads allow testing of thin sheet metals. 'Wide testing range': from soft metal such as lead up to medium hardened steels. Small size of indentation makes it a non-destructive testing on finished components. Advanced Window 95/NT based software. Latest GUI Features Online indentation setting and focusing on PC monitor. User-friendly software with all help file and Window Features. Advance image processing: Algorithms implemented for precise calculation of hardness numbers with various options to cover all ranges of specimen PC requirements Can be connected to Laptop or Desktop PC. Easy to carry anywhere and handy for use with easy setup. Minimum Petnium-II with 64 MB RAM. Windows 98 Operating System. (PC not included in standard scope of supply.) One USB 2.0 and one RS232 (serial) interface (9 pin) is required and it is recommended for Laptop to use external USB to serial converter for RS232 interface SPECIFICATIONS UNIT Mech.CS.VM50PC Total Lands kg. 5,10,20,30 & 50 Max. Testing Height mm 200 Scale least count mm 0.001 Throat Depth mm 135 Machine Dimensions (Approx.) mm L 585 x W 290 x H 860 Net Weight (Approx.) kg. 70 Power Supply 220 V,50 Hz, 1 Phase Batch file Processing Option for data/storage and reports generation. Statistical Evaluation Software for calculating standard deviation, mode medium, histogram etc.

...more

Vickers Standard (Mech.CS.VM-50)

Our Vickers Standard Hardness Testing Machine is made using the advanced technology that ensures its premium quality. In our product, the machine frame is designed sturdy in order to accommodate the high precision loading system. Click Here For more Details

...more

Vickers Hardness Testing Machine

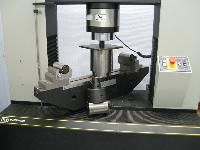

Universal Testing Machine - Mechanical - Mech.CS.UTM

Features Mechatronic Control System's range of Universal Testing Machines are widely appreciated in different industries for the following features: Loading accuracy as high as ±1%. Training roll autographic recorder supplied as standard to enable study of the behavior of materials. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Motorised loading and unloading cycle. Large effective clearance between columns enables testing of standard specimens as well as structures. Simple controls for ease of operation. Safe operation ensured by means of safety devices. Fully enclosed and protected pendulum. Principle of Operations Operation of the machine is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The system is ideal since it replaces transmission of load : through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self - lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a leverage to the pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of the specimen. Machine consists of: • Straining Unit • Control Panel Power Pack • Hydraulic Controls • Load Indicator System • Automatic Continuous Roll Load - Elongation Recorder Technical Data

...more

Universal Testing Machine - Computerised - Mech.CS.UTE

Application Mechatronic Control System is a prominent manufacturer of Universal Testing Machine which is available in electronic and computerized functioning. This machine is used to test the tensile and compressive properties of material. The reason Universal Testing machine is named so because it can perform all the tests right from compression, bending to tension and examine the material in all mechanical properties. We offer these in grade of 10T, 20T, 40T, 60T and 100T. Accuracy & Calibration All Mechatronic Control System's Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS: 1828-1975. Mechatronic Control System's Universal Testing Machines Comply with grade "A" of BS : 1610 : 1964 and grade 1.0 of IS -1828-1975 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the maximum permissible error is 0.2% of the full reading. Principle of Operations Operation of the universal testing machine is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The system is ideal since it replaces transmission of load : through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self - lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a leverage to the pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of the specimen. Machine consists of: • Straining Unit • Control Panel Power Pack • Hydraulic Controls • Load Indicator System • Automatic Continuous Roll Load - Elongation Recorder Electronic Extensometer Mechatronic Control System offers electronic extensometer EE 1 to measure material extension with a resolution of one micron. Strain gauge type extensometer to be used up to elastic limit to determine important parameters like 0.1%, 0.2% proof stress and Young's Modulus. Technical Data

...more

universal tester

The load transmitted to the cylinder of the dynamometer is transferred through a leverage to the pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen.

...more

Universal Tensile Testing Machine

Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS: 1828-1975. An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the maximum permissible error is 0.2% of the full reading.

...more

Torsion Testing Machine - Mech.CS.TT

FEATURES Suitable for Torsion and Twist test on various metal rods and flats. Torque Measurement by pendulum dynamometer system. Auto torque selector to adjust torque ranges. Geared motor to apply torque to specimen through gearbox. Autographic recorder for relation between torque and angle of twist. Accuracy + 1 % of the true torque TECHNICAL DATA SPECIFICATIONS Mech.CS - TT 10 Mech.CS - TT 20 Mech.CS - TT 50 Max. Torque Capacity (Nm) 100 200 500 Torque Range (Nm) 20,50, 100 50, 100,200 50,100,250,500 Nos. of Division on dial 500 500 500 Test speed and direction 1.5 RPM Reverse 1.5 RPM Reverse 1.5 RPM Reverse Clearance between grips (mm) 0-400 0-450 0-500 Grips for square bar (mm) 3-6 6-9 9- 12 7- 10 10- 15 15-20 10- 17 17-24 24-30

...more

Torsion Testing Machine

Mechatronic Control System is one of the leading companies, which is involved in the manufacturing and supplying of Torsion Testing Machines. These Torsion Testing Machines are designed with precision under the supervision of experts. Model : Mech.CS.TT Features : Auto torque selector to adjust torque rangesGeared motor to apply torque to specimen through gearboxAutographic recorder for relation between torque and angle of twistAccuracy + 1 % of the true torqueSuitable for Torsion and Twist test on various metal rods and flatsTorque Measurement by pendulum dynamometer system Attributes : Offer reliable resultsAnti-corrosiveHassle free operationsLess time consuming

...more

Tensile Testing Machine - Computerised

Mechatronic Control System is engaged in manufacturing Tensile Testing Machines in the range of 2T, 2.5T and 5T. Tensile testing machines are available in mechanical, electronic & computerized format and are suited for studying mechanical behavior of different material such as metals, polymers and elastomers. Mechatronic Control System manufacture TNE series machines tat are electro mechanical screw driven machines with precision screw and column construction. Tensile testing machine can be availed in variable speed drives and tow options. The model most preferred by our clients is the acme-threaded screw with DC motor drive and ball lead screw with servo drive. TNE SERIES TNEseries machines are available with following options Depending upon test requirements and budget, best combination can be selected. DRIVE - SD: Drive dd is with DC motor with thyrister drive to give speed ratio As per sample std. Requirement. DRIVE - SD: Drive SD is with servo motor & PWM transister drive to give speed ratio As per sample std. Requirement.

...more

tensile testing equipment

Proving our dominance in material testing machines domain, we have formed tie-ups with reputed and prestigious organizations, defense labs, research institutes, metallurgical labs, engineering colleges and steel industries in India and abroad.

...more

Spring Testing Machine

Mechatronic Control System’s range of Spring Testing Machines is widely used for quick and accurate testing of compression & tension test of springs. The machine comprise of two hard chrome plated columns with fine cut single screw with hand wheel for manual loading and unloading arrangement. The machine uses a high precision Load Cell for measurement of force. For displacement measurement Mechanical Linear Scale or Digital Vernier Caliper or Rotary Encoder is used. Measuring System is based on latest microcontroller / microprocessor based electronic panels with all facilities. Options Digital Vernier Scale with 0.01 mm resolution for displacement measurement (6” or 12”) Rotary Encoder with separate digital unit with resolution 0.1 mm or 0.01mm 9 /24 pin Dot Matrix printer interface Serial RS-232 interface with windows Xp based advanced software for real-time graph and automatic result calculations Motorized Loading Operations Features Microprocessor / Microcontroller Based Unit Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick And Accurate Measurement Interchangeable Load Cells Modulus Data For Load & Displacement (For Selectable Models With Software) Optional Dot Matrix Printer Interface Optional Windows Xp Based Software With Rs-232 Interface Simple Controls For Ease Of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation With Drive & Motor Available Technical Specifications Model Mech.CS.STM-20 Mech.CS.STM-200 Mech.CS.STM-500 Maximum Capacity 20 / 10 / 5 Kg 200 / 100 / 50 Kg 500/ 300 Kg Width between Columns 160 mm 160 mm 250 mm Maximum Crosshead Travel 160 mm 160 mm 250 mm Force Measuring Resolution 1 gm 10 gm 0.1 kg Displacement Measurement Options Scale Type Mechanical Scale Digital Vernier Scale Rotary Encoder Range 0 – 150 mm 0 – 150 mm 0 – 150 mm Resolution 1.0 mm 0.01 mm 0.1 / 0.01 mm

...more

Spring Load Testing Machine

Microprocessor Microcontroller Based Unit Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick And Accurate Measurement Interchangeable Load Cells Modulus Data For Load & Displacement (For Selectable Models With Software) Optional Dot Matrix Printer Interface Optional Windows Xp Based Software With Rs-232 Interface Simple Controls For Ease Of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation With Drive & Motor Available

...more

Rockwell Hardness Testing Machine - Mech.CS.RAS

Features Mechatronic Control System Hardness Testers Models SE RAS, SE RASM, SE RAB-1, SE RAB-250, SE TWIN are manually operated. All these models are suitable for testing hardness of metals & alloys of all kinds hard or soft, whether flat, round or irregular in shape. These testers are simple in design & easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for Engg. Colleges, laboratories, toolroom, inspection departments, factories etc. These testers strictly conform to IS: 3804-1988, BS: 891 parts 1&2, ASTM:E18 for Rockwell Test, IS: 2281-1983, BS: 240, ASTM:E10 for rockwell Test & IS: 5073-1988, ASTM:E18 for Rockwell Superficial Test. MODEL : Mech.CS.RAS : Automatic load selection with automatic zero setting dial gauge. Manual Operation. MODEL : Mech.CS.RASM : Similar to 'Mech.CS.RAS1 but motorised model. Semiautomatic operation for production testing. Drive motor single phase 230V 50 cycles. ROCKWELL/rockwell COMBINED SYSTEM MODEL Mech.CS. RAB-1 : Automatic load selection with automatic zero setting dial gauge. Facility for rockwell Tests with 187.5 kgf. load with 2.5 mm ball indentor, additional load 250 kgf. with 5 mm ball Indentor for testing hardness of non- ferrous metals. Manual Operation. MODEL : Mech.CS. RAB-250 : Similar to 'Mech.CS.RAB-11 but bigger capacity Diamond Holder is guided in a set of two bail cage, which enables testing of small pins having dia. less than 6 mm (upto 3mni dia) ROCKWELL/ROCKWELL SUPERFICIAL COMBINED SYSTEM MODEL : Mech.CS.TWIN : Manual load selection with automatic zero setting dial gauge. Manual Operation. Diamond Holder is guided in a set of two ball cage, which enables testing of small pins having dia. less than 6 mm. (upto 3 mm dia.) SERIES RASN: Rockwell & Rockwell superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force & the measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement or hardness value. OPERATION : For Rockwell & Rockwell Superficial OPERATION : For Rockwell & Rockwell Superficial Test : In case of 'RASN' series machines for Rockwell or Rockwell Superficial Test a preliminary test force in first applied & then indicator is automatically set for zero. Quickly thereafter & additional test force is applied without removing the preliminary test force. When the penetration is stabilized, the additional test force is removed & the hardness number is shown directly on the indicator. For rockwell Test The operation is exactly same as above. However, the diameter of impression is measured out side of machine by rockwell microscope. rockwell Hardness number is found out by referring corresponding hardness tables showing hardness number against di. of indentation for specified ball diameter and test force. MODEL RASN Suitable for Rockwell Tests. Manual operated. Priliminary Test Force - 98.7N (10 kgf.) Additional Test Force - 490.3, 882.6,1373N (50, 90,140 kgf.) Total Test Force - 588.4, 980.7,1471N (60,100,150 kgf.) Test Force selection by external dialing. Auto zero setting dial gauge. Rockwell cum rockwell Tester: Model RASN (B): Same as RASN above in additional Additional Test Force - 1471, 2354N (177.5, 240 kgf.) Total Test Force - 1839, 2452N (187.5, 250 kgf.) MODEL RASN (M) Suitable for Rockwell Tests. Motorised for automatic operation cycle (load / dwell / unload) Additional Test Force - 490.3, 882.6,1373N (50, 90,140 kgf.) Total Test Force - 588.4, 980.7,1471N (60,100,150 kgf.) Test Force selection by external dialing. Auto zero setting dial gauge. MODEL RASN (E) : (DIGITAL) Mechatronic Control System’s Hardness Testers Models RAS, This models is suitable for testing hardness of metals & alloys of all kinds hard or soft, whether flat, round or irregular in shape. These testers are simple in design & easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for Engg. Colleges, laboratories, tool room, inspection departments, factories etc. These testers strictly conform to IS: 3804-1988, BS: 891 parts 1&2, ASTM:E18 for Rockwell Test, IS: 2281-1983, BS: 240, ASTM:E10 for Rockwell Test & IS: 5073-1988, ASTM:E18 for Rockwell Superficial Test. MODEL : RAS Automatic load selection with automatic zero setting dial gauge. Manual Operation.

...more

Rockwell Digital (Mech.CS.RAS(D)

We are counted amongst the leading manufacturers and suppliers of Rockwell Digital Hardness Testing Machine. We offer the premium quality Rockwell Digital that is made by using the advanced technology which ensures better performance and more precise readings. Click Here For More Details

...more

Portable Hardness Testing Machine - Mech.CS.PHTM

Portable Rockwell Hardness Tester is developed to meet the demands of a light weight instrument which can be used to carry out by a universally recognized method of hardness testing. Rockwell Method This hardness tester can be used in variety of applications and is readily adjustable to a wide range of sizes and shapes which are difficult to test in a standard table model hardness tester.The machine as designed for carrying out Rockwell tests comparable to table model hardness tester because, the basic things, such as shape of penetration, measurement and loads are same in both systems. 01 Upper clamp 02 Lower clamp 03 Support anvil 04 Adjusting screws 05 Knurled Knob 06 Penetrator 07 Penetrator tightening screw 08 Weight bar 09 Loading Screw 10 Handle 11 Loading dial indicator 12 Indicator seat support 13 Indicator seat 14 Penetration measuring indict The above photograph gives the general arrangement of the hardness tester.The system carries a weight bar (8) pivoted at central point. When the load is applied by the loading screw (9), at one end of this weigh bar, it is deflected and the other end of this bar carrying penetrator forces down into the test specimen. This deflection of weight bar which is proportional to the applied load is indication of the loading dial indicator (11). Besides this loading dial indicator, there is one penetration measuring indicator(14) which measures the actual penetration of the penetrator into the test specimen. The hardness value of the specimen is read directly on this indicator.The frame carries two adjusting screws and gear train. By rotating the knurled knob the distance between the penetrator and the support-anvil can be adjusted. Method of Test Select proper penetrator (6) depending upon the material to be tested.Take precaution so thet the penetrator does not project beyond the Upper clamp (1). For this, the loading screw (9) should be sufficiently taken back.Place the test specimen securely on suitable anvil (3)Clamp test specimen firmly between upper clamp (1) and support anvil (3) by rotating the knurled knob (5) on the lower clamp (2). DO NOT APPLY EXTRA PRESSURE.CHECK ZERO SETTING LOAD INDICATOR (11). Rotate bezel to bring pointer over small black dot for zero load.. Apply 10 kgf (98.07 N). major load screw (9) in clockwise direction such that the pointer on the load indenter (11) comes on set position.Check zero setting of penetrator indicator (14). Rotate bezel to bring pointer to ‘O’ on the black scale. For ‘C’ scale use diamond penetrator against load of 150 kgf (1471 N) and for ‘A’ scale use same diamond penetrator against a load of 60 kgf (588.4 N). For ‘B’ scale use 1/16 ball penetrator against a load of 100 kgf (980.7 N). Take off major load by turning the loading screw in anticlockwise direction, such that only minor load of 10 kgf. (98.07) remains in action – (pointer back to ‘set’ position).Hardness value in Rockwell scale is directly indicated on the penetrator indicator (14). Read of number on black scale is diamond penetrator. Read off number on red scale is ball penetratorRelease load completely by taking back the loading screw (9)Turn the knurled knob (5) in anticlockwise direction to loosen clamp and thus the test specimen Specification Maximum test height 110 mm Throat capacity 55 mm Accessories: Flat Anvil 1 No. 'V' Anvil 1 No. Test Blocks 2 Nos. 1/16" Ball penetrator 1 No.

...more

Model Mech.CS.B3000(J)

Simplest model of rockwell Hardness Testing Machine with mechanical design. Loading, unloading manual, Best suitable for testing batch quantities. Mechatronic Control System Hardness Testers Model B-3000(H), (O) & (J) are precision engineered to IS:2281- 1968, BS:240 and ASTM:E10. However B-3000(H), (O), (J) are most suitable for production testing. These machines are designed to measure hardness of casting, forgings, other metals and alloys of all kinds, hard or soft, whether flat, round or irregular in shape. Technical Data SPECIFICATIONS UNIT Mech.CS.B3000(J) Loads 200 500 to 3000 in stages of 250 Initial Load kgf Nil Max. Testing Height mm 254 Depth of Throat mm 150 Max. Depth of elevating screw below base mm 0 Size of Base mm 255x495 Machine Height mm 860 Net Weight (Approx.) kg. 210 Drive Motor HP Nil Standard Accessories MODEL SE B-3000 J Testing table 200 mm 1 pc Testing table Y groove 70 mm Nil Ball Holder 5 mm 1 pc Ball Holder 10 mm 1 pc Test Block HB - 5/750 Nil Test Block HB - 10/3000 1 pc rockwell Microscope 1 pc Allen Spanner 4 pes Instruction Manual 1 book

...more

Mechanical Universal Testing Machine

Mechatronic Control System is well-known for the manufacturing and supplying of Mechanical Universal Testing Machines. The hassle free functioning of these Mechanical Universal Testing Machines has raised their demand among the clients. Model : Mech.CS.UTM Features : Loading accuracy as high as ±1%Motorized loading and unloading cycleSimple controls for ease of operationSafe operation ensured by means of safety devicesFully enclosed and protected pendulumHigh reading accuracy due to large size and design of dialEasy change from plain to threaded and screwed specimensTraining roll autographic recorder supplied as standard to enable study of the behavior of materialsLarge effective clearance between columns enables testing of standard specimens as well as structuresWide range of standard and special accessories, including load stabilizer Attributes : High performanceNon corrosiveEfficient resultsSaves timeEasy to operate Click Here For More Detail

...more

Mechanical Rockwell (Mech.CS.RAS)

We are counted amongst the leading manufacturers and suppliers of Mechanical Rockwell Hardness Testing Machine. We offer the premium quality Mechanical Rockwell that is made by using the advanced technology which ensures better performance and more precise readings. Click Here For More Details

...more

Mechanical Impact Testing Machine

Mechatronic Control System is the trusted Manufacturer and Supplier of Mechanical Impact Testing Machines. These Mechanical Impact Testing Machines are known for their high performance and efficient results in varied applications. Model : Mech.CS.IT-30 Used for : Testing the resistance of metal and its alloys to external impactsConducting IZOD & CHARPY Test Confirm to following standards : BS:131:PART 4-1972 (Amended 15 Aug. 1993)BSEN : 10045 - 2 : 1993 Featured with : Pendulum is mounted on antifriction bearingsTwo starting positions :Upper one for CHARPYLower one for IZOD TestingPendulum swing down to break the specimenEnergy absorbed in doing so is measured as the difference between the height of drop before rupture & height of raise after rapture of the test specimen and is read from the maximum pointer on the dial scaleCHARPY Testing Equipment :CHARPY test piece rests on alloy steel supports anvils fitted on the base of the machine rigidly held in position by alien screwsEnd stopper is provided for quickly & accurately locating the test piece centrally between the supportsIZOD Testing Equipment :IZOD test piece is clamped vertically in IZOD support anvils, fitted on the base of the machineSupport is provided with a machined vertical groove to suit the test piece sizeFront clamp piece & alien screw enable clamping of the test piece in correct height with the help of IZOD setting gauge suppliedControls of Pendulum :Pendulum supported in the starting positions is by a self resetting latchRelease mechanism is operated by leverPendulum release latch is operated only when this lever is operatedStrikers & Supporters :Strikers & one combined support available for fitting into the Pendulum & on to the base of the machine for IZOD, CHARPY testChanging from one striker to another is achieved simply by fixing the new striker into its position

...more

Mechanical Extensometer

Mechatronic Control System's range of Universal Testing Machines are widely appreciated in different industries for the following features:Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Motorised loading and unloading cycle. Large effective clearance between columns enables testing of standard specimens as well as structures. Simple controls for ease of operation.

...more

Material Testing Machine

Impact Testing Machine - Mechanical - Mech.CS.IT30

Mechatronic Control System is one of the leading manufacturer and exporter of Impact Testing Machines. We design and build different models of impact testing machines with utmost precision, with the help of state of the art technology. Impact testing machine is used to test the resistance of metal & alloys to external impacts. GENERAL DESCRIPTION The Pendulum Impact Tester Model MCS-IT 30 is designed for conduction Izod & Charpy Test. The test methods confirm to BS:131:PART 4-1972 (Amended 15 Aug. 1993) & BSEN: 10045 - 2 : 1993. The Pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy and the lower one for Izod testing. On release, the Pendulum swing down to break the specimen and the energy absorbed in doing so is measured as the difference between the height of drop before rupture & height of raise after repture of the test specimenn and is read from the maximum pointer on the dail scale. Charpy Test The Charpy test piece rests on alloy steel supports anvils fitted on the base of the machine rigidly held in position by alien screws. End stopper is provided for quickly & accurately locating the test piece centrally between the supports. Izod Test The Izod test piece is clamped vertically in Izod support anvils, fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece & alien screw enable clamping of the test piece in correct height with the help of Izod setting gauge supplied. Controls of Pendulum The Pendulum supported in the starting positions is by a self resetting latch. The release mechanism is operated by lever. The Pendulum release latch is operated only when this lever is operated. Strikers & Supporters There are strikers & one combined support available for fitting into the Pendulum & on to the base of the machine for Izod, Charpy test. Changing from one striker to another is achieved simply by fixing the new striker into its position. SPECIFICATIONS Mech.CS.IT30 Mech.CS.DIT30 Maximum Capacity 300 J/168 J 300 J / 170 J Minimum Scale Graduation 2J 0.5 J Overall Size (Approx.) 1.65 m (H) 1.65 m x 0.45 mx 1.1 m x 0.45 mx 1.65 m (H) Net Weight (Approx.) 375 Kg. 375 Kg. Optional Accessories: Caliper gauge for checking V notch for Izod & Charpy as per BS:131 :PART 1, 2, 3 Depth notch gauge including V & U notch, angle & radius. Self centering tong. V - notch milling cutter. U - notch milling cutter

...moreBe first to Rate

Rate ThisOpening Hours