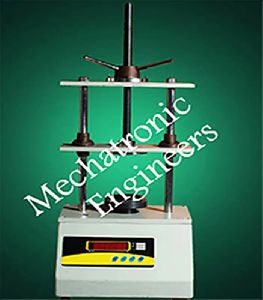

Spring Testing Machine

1 Piece (MOQ)

Features Microcontroller Based Advanced System Unit Force Measurement Accuracy ± 1% of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick and Accurate Measurement Interchangeable Load Cells Simple Controls for Ease of Operation. Modulus Data for Load & Displacement (For Selectable Models with Software) Safe Operation Ensured by Means of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation with Drive & Motor Available

Voltage : 220V

Automatic Grade : Automatic

Driven Type : Electric

Warrenty : 1 Year

...more

Rockwell Cum Brinell Hardness Testing Machine

1 Piece (MOQ)

MODEL : ME-RABI-250 Automatic load selection with automatic zero setting dial gauge. Manual Operation. Preliminary Test Force – 10 kgf Test Loads for Rockwell – 60, 100, 150 kgf Test Loads for Brinell – 187.5, 250 kgf Test Force selection by external dialing.

...more

Impact Testing Machine

1 Piece (MOQ)

The pendulum Impact Tester of all the above models are designed for conducting Izod, Charpy test. The test methods confirm to BS : 131 : part 4-1972 (amended 15 Aug. 1993)BSEN : 10045-2 : 1993 & ASTM : E-23-94a. The Pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy & the lower one for Izod testing. On release, the pendulum swings down to brake the specimen, and the energy absorbed in doing so is measured as the difference between the height of drop before rupture and the height of rise after rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on Digital Panel in case of digital models) Controls of Pendulum: The Pendulum supports in the starting positions are by a self-resetting latch. The release mechanism is operated by a lever. The pendulum release latch is operated only when this lever is operated Strikers & Supports: There are two strikers and one combined support available for lifting into the pendulum and on to the base of the machine for Izod., Charpy test, changing from one striker to another is achieved simply by fixing the new striker into its position. CHARPY TEST: The Charpy test piece rests on alloy support anvils, fitted on the base of the machine rigidly held in position by Allen screws. The end stopper is provided for quickly and accurately locating the test piece centrally between the supports. IZOD TEST: The Izod test is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the test piece at an incorrect height with the help of the Izod setting gauge supplied. MODEL ME-ASTM-E-23 This impact tester offered with 300J energy exclusively for the Charpy test confirming to ASTM- E-23. This machine is geometrically checked in the works to the more stringent requirements of the American standard. The accuracy of the machine is then verified by PROOF TEST by testing standard test specimens supplied by the NIST, USA. All two sets of the five specimens must agree with the normal values within certain tolerance specified. OPTIONAL ACCESSORIES Caliper gauge for checking V notch for Izod & Charpy. Templates for checking 10 x 10 mm cross-section of Izod / Charpy test specimen Depth notch gauge including V & U notch gauges for checking depth blow V/U notch, angle, and radius. Self-centering tong for quick and accurate setting of Charpy test specimen. ‘V’ notch milling cutter ‘U’ notch milling cutter

Driven Type : Electric

...more

Tensile Tetsing Machine

1 Piece (MOQ)

We are offering Three Types of Models Model: ME-TNE-SD: Double Ball Screw with Servo Motor Servo Drive Model: ME-TNE-DD: Acme Threaded Double Screw with AC Motor Drive Model ME-TNE: Single Screw with Induction Motor Machine Features Fully Computer Controlled Mechanism Advanced Software is compatible with Latest Windows Version. Variable Speed Drive Options available with DC / AC Servo Drive Advanced Digital Control Panel automatically identify Load Cell Capacity Various Clamping / Gripping options available as per specific Text requirement. Overload / Overtravel Safety guard installed Advanced Digital Control System with Digital Display of Load, Deflation & Extension Machine Operations like Test Speed, Direction are controlled from the Advanced Digital Control Panel. Manual Operation (Panel Control Mode) Sealed membrane keyboard with numeric keypad • Pre Determined Test Data • Load/Force Tare & Reset Deflection / Extension Buttons • Load / Force vs Deflection Graph is available on Dot-matrix Printer • Auto Scaling for Graph Plotting • Selection of Stop / Return of crosshead and direction • Results include Ultimate Load, Maximum Deflection, Ultimate Tensile Strength & Percentage Elongation Computerized Operation (Software Control Mode) Advanced Digital Control Panel is connected to the computer through RS – 232 port & Latest Windows-based Advanced Software. The control is transferred to computers and with the help of Windows-based Software, complete testing can be performed. Software Features Supports Windows XP / 7 / 10 User-friendly Windows Software for complete test control Real-Time Graph with an online display of Load / Force, Deflection & Extension Wide range of input test data Unit interchangeability for input data and output results as per Standard Extensive Graphics, Curve Fitting, Zooming Results include Ultimate Load, Ultimate Tensile Strength, Maximum Deflection. %Elongation, Area Under the Curve, % Reduction in Area, Yield Load, Yield Strength, Proof Load, Proof Stress Multi Graphs are available Load vs Deflection, Stress vs Strain, Load vs Elongation. Extensometer MECHATRONIC ENGINEERS’ digital extensometer Model ME-EE-2 is a Strain Gauge type digital extensometer to measure material’ extension while conduction Tensile Test with a resolution of one micron (0.001 mm). It is designed to be clamped directly on the test specimen. This is used to measure strain up to elastic limits to determine important parameters like 0.1% to 1% proof stress and young’s modulus. ME-EE-2 has two fixed gauge lengths of 25 mm & 50 mm. Change of gauge length is by means of replacing button knife-edge extender. ME-EE-2 is manufactured from high strength lightweight aluminum with a durable anodized finish. The knife – edges are made from oil hardened tool steel to withstand heavy, usage. It Supports a maximum Diameter / Thickness of 40 mm & a maximum extension of 2 mm suitable for Round, Flat, Pipe & Tor Steel / TMT Steel applications. MECHATRONIC ENGINEERS’ digital Long Travel Extensometer Model ME-LT- 600 is a balanced clip-on type extensometer used to measure strain accurately. In association with the Advanced Digital Control Panel, the true extension of the sample with a 0.01 mm resolution is directly displayed. The distance between two small clamps attached to the sample can be pre-set to any desired gauge length. Cords attached to each clamp transmit the movement to two sensors mounted at the top of the extensometer column. These produce pulses which drive the digital strain display thus detecting strain accurately. This is suitable for rubber & semi-rigid plastics. The maximum extension is 600 mm & gauge length continuously variable. Optional Accessories Digital Extensometer Model ME-EE-2 Digital Long Travel Extensometer Model ME-LT- 600 Vice Type Grips Bending Fixture Special Grips as per requirement Shear Test Attachment Additional Load Cells (50N, 100N, 250N, 500N, 1kN, 2.5kN, 5kN, 10kN, 25kN, 5

Type : Motorized

Voltage : 440V

Automatic Grade : Automatic

Power : 3-5kw

Application : Testing

...more

Motorized Broaching Machine

1 Piece (MOQ)

Country of Origin : India

Automatic Grade : Automatic

Motorized Impact Testing Machine

1 Piece (MOQ)

Features Capacity: Charpy 300J / Izod: 178J Motorized Lifting operation of pendulum Hammer so there is no strain & fatigue to the operator while lifting the pendulum hammer frequently. Only one operator can operate the machine easily & rapidly. To stop the pendulum swing solenoid Magnetic Brake is provided. To prevent accident large safety guard with openable doors & with an interlocking system is provided for complete safety. A transparent acrylic glass sheet is fitted to safeguard. Machine conforms to ASTM-E 23, BSEN ISO 148 & IS standards (for IZOD & Charpy scales). Total Maintenance-free Impact Machine. Higher capacity 500, 600,750 Joules impact machines are also available. The pendulum Impact Tester of all the above models are designed for conducting Izod, Charpy test. The test methods confirm to BS : 131 : part 4-1972 (amended 15 Aug. 1993)BSEN : 10045-2 : 1993 & ASTM : E-23-94a. The Pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy & the lower one for Izod testing. On release, the pendulum swings down to brake the specimen, and the energy absorbed in doing so is measured as the difference between the height of drop before rupture and the height of rise after rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on Digital Panel in case of digital models) Controls of Pendulum: The Pendulum supports in the starting positions is by a self-resetting latch. The release mechanism is operated by a lever. The pendulum release latch is operated only when this lever is operated Strikers & Supports: There are two strikers and one combined support available for lifting into the pendulum and on to the base of the machine for Izod., Charpy test, changing from one striker to another is achieved simply by fixing the new striker into its position. CHARPY TEST: The Charpy test piece rests on alloy support anvils, fitted on the base of the machine rigidly held in position by Allen screws. The end stopper is provided for quickly and accurately locating the test piece centrally between the supports. IZOD TEST: The Izod test is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the test piece incorrect height with the help of the Izod setting gauge supplied. MODEL ME-ASTM-E-23-M This impact tester offered with 300J energy exclusively for the Charpy test confirming to ASTM- E-23. This machine is geometrically checked in the works to the more stringent requirements of the American standard. The accuracy of the machine is then verified by PROOF TEST by testing standard test specimens supplied by the NIST, USA. All two sets of the five specimens must agree with the normal values within certain tolerance specified. OPTIONAL ACCESSORIES Caliper gauge for checking V notch for Izod & Charpy Templates for checking 10 x 10 mm cross-section of Izod / Charpy test specimen Depth notch gauge including V & U notch gauges for checking depth blow V/U notch, angle and radius Self-centering tong for quick and accurate setting of Charpy test specimen ‘V’ notch milling cutter ‘U’ notch milling cutter

Voltage : 220V

Driven Type : Electric

Display Type : Digital and Analog

...more

Mechanical Extensometer

1 Piece (MOQ)

Extensometer is essential to measure the elongation of the test specimen under load, to have its mechanical properties. Mechatronic Engineers’ Extensometer Model ME-EM 1 is intended to serve the above purpose.

Feature : Durable

...more

Vickers Hardness Testing Machine

1 Piece (MOQ)

Features Tiny indentation allows the testing of precision finished parts. The thin sheet metal is perfectly tested. Because the applied load is very small. Motorized loading and unloading cycle. Built-in projection screen to get accurate results. The same hardness number is obtained on the same specimen, regardless of the load applied. Wide testing range, from a soft metal such as lead, Upto the hardest, like hardened steel. Construction To accommodate the high precision loading system & an optical projection screen, the machine frame is designed sturdy. The specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied to a diamond penetrator by means of a lever & weights. The load is removed automatically after a specific lapse of time. The objective is indexed with the test piece & the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

...more

Vickers Hardness Testing Machine Computerized

1 Piece (MOQ)

Features Fully Computerized (PC Based) Vickers Hardness Machine. Direct and accurate measurement of Vickers Hardness Number using “State of Art” image processing technology. ‘Wide testing range: from soft metal such as the lead up to medium hardened steels. High accuracy and repeatability of measurement at all loads. Faster measurement yielding to higher productivity. The small size of indentation makes non-destructive testing on finished components. Motorized loading and unloading cycle. Small loads allow the testing of thin sheet metals. Advanced Window XP based software. Latest GUI Features: User-friendly software with all help files and Window Features. Online indentation setting and focusing on the PC monitor. Advance image processing Algorithms implemented for a precise calculation of hardness numbers with various options to cover all ranges of specimens. Batch file Processing : Option for data/storage and reports generation. Statistical Evaluation: Software for calculating standard deviation, mode medium, histogram, etc. Options in calibration mode: Calibration / Verification on PC monitor makes it easier to operate. Computerized Vickers Hardness Tester is a simple and accurate means to produce automatically measure the diamond indentation to give Vickers hardness numbers. These testers are suitable for measuring the hardness of precision metallic parts with a wide testing range – from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS 1754 – 2002. Construction To accommodate the high precision loading system & an optical projection screen, the machine frame is designed sturdy. The specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied to a diamond penetrator by means of a lever & weights. The load is removed automatically after a specific lapse of time. The objective is indexed with the test piece & the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

...more

Universal Testing Machine

1 Piece (MOQ)

Applications Mechatronic Engineers make Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted Accuracy & Calibration All Mechatronic Engineers make Universal Testing Machines are closely controlled for sensitivity, accuracy, and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS 1828-1975. Mechatronic Engineers Universal Testing Machines Comply with grade “A” of BS: 1610: 1964 and grade 1.0 of IS -1828-1975 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the maximum permissible error is 0.2% of the full reading. Principle of Operation The operation of the machine is by hydraulic transmission of load from the test specimen through DIGITAL PRESSURE TRANSDUCER to a separately housed load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on the rupture of test pieces. The load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the DIGITAL PRESSURE TRANSDUCER housed in the control panel. The DIGITAL PRESSURE TRANSDUCER gives a signal to the DIGITAL ELECTRONIC DISPLAY UNIT corresponding to the load exerted by the main ram. Simultaneously the digital Electronic Encoder fitted on the straining unit gives the mechanical displacement to the DIGITAL ELECTRONIC DISPLAY UNIT. Both the signals are processed by Microprocessor and LOAD and DISPLACEMENT is displayed on the to DIGITAL ELECTRONIC DISPLAY UNIT Machine consists of Machine consists of Straining Unit This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured by revealing the cylinder and ram of any possible side loading by the provision of ball seating. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads, Compression, transverse, bending, shear, and hardness tests are conducted between the lower crosshead and the table. The lower cross-head can be raised or lowered rapidly by operating the screwed columns thus facilitating ease of fixing of the test specimen. Control Panel The Control Panel consists of a power pack complete with drive motor and an oil tank, control valves with to DIGITAL ELECTRONIC DISPLAY UNIT. A pressure transducer is connected for load indicator and a rotary encoder for elongation with a resolution of 0.1 mm, is provided to measure the deformation of the specimen Power Pack The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls Hand operates wheels are used to control the flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken. Load Deflection Indicator It is a microprocessor-based electronic control panel connected with a machine using a Pressure Transducer, Rotary Encoder, and Electronic Extensometer. Using the RS-232 serial communication port our s/w communicates with the machine and gets real-time Load, Deflection, and Extension, and shows on the computer. Electronic digital displays Load Elongation and extension. Facility to hold peak – load and tare facility to make load zero. El

Country of Origin : India

Application : Testing

Voltage : 440V

Power : 5-10kw

...more

Rockwell Hardness Testing Machine

1 Piece (MOQ)

Model ME-RAS Digital Digital Hardness Tester for Rockwell tests. Motorized for automatic operation cycle i.e. load / dwell / unload. Preliminary Test Force – 98.07N (10 kgf.) Additional Test Force – 490.3, 882.6, 1373N (50, 90, 140 kgf.) Total Test Force – 588.4, 980.7, 1471N (60, 100, 150 kgf.) Test Force selection by external dialing. Set position with LED bar indicator for easy operation. Keyboard entry through reliable membrane switches for scale / GO-NOGO / dwell time selection. Large size scale display for easy reading with 0.1 Rockwell resolution. Parallel output for connecting dot matrix printer to get results indicating a serial number of tests, hardness scales, hardness value, and high/good / low indication.

...more

Universal Testing Machine

1 Piece (MOQ)

Highlighted Features Front Open Type Cross Head Hydraulic Wedge Action Grips Fully Customized Advance Software Long test stroke and dual test space Loading accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials Motor-driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of the test specimen. Simplicity in reading because of digital readouts Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for ease of operation Robust straining frame of an extremely rigid construction Safe operation ensured by means of safety devices. Fully enclosed and protected pressure transducer RS 232 serial port to transfer data to a computer for analysis/storage evaluation etc. Manual control & release valve operation Machine Capacity: 100 kN, 200 kN, 400 kN, 600 kN, 1000 kN, 1200 kN, 1500 kN, and 2000 kN Servo Controlled Models are Available Applications Mechatronic Engineers make Universal Testing Machine Model range ME-FE-UTE is designed for testing metals and other materials under Tension, Compression, Bending, Re-Bending, Transverse and Shear Tests. A hardness test on metals can also be conducted. This Special model is designed as Front Open Crosshead for easy Specimen changing with Wedge Action Hydraulic Grips Accuracy & Calibration All Mechatronic Engineers make Universal Testing Machines that are closely controlled for sensitivity, accuracy, and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards BS-1610:Part1:1992 and IS-1828:Part1:1991. Mechatronic Engineers Universal Testing Machines Comply with grade “A” of BS-1610:Part1:1992 and grade IS-1828:Part1:1991 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the maximum permissible error is 0.2% of the full reading. Principle of Operation Operation of the machine is by hydraulic transmission of load from the test specimen through DIGITAL PRESSURE TRANSDUCER to a separately housed load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on the rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the DIGITAL PRESSURE TRANSDUCER housed in the control panel. The DIGITAL PRESSURE TRANSDUCER gives signal to DIGITAL ELECTRONIC DISPLAY UNIT corresponding to the load exerted by the main ram. Simultaneously the digital Electronic Encoder fitted on the straining unit gives the mechanical displacement to the DIGITAL ELECTRONIC DISPLAY UNIT. Both the signals are processed by Microprocessor and LOAD and DISPLACEMENT is displayed on the to DIGITAL ELECTRONIC DISPLAY UNIT Machine consists of Straining Unit This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured be reveling the cylinder and ram of any possible side loading by the provision of ball seating. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads, Compression, transverse, bending, shear, and hardness tests are conducted between the lower cross head and the table. The lower cross-head can be raised or lowered rapidly by operating the screwed columns thus facilitating ease of fixing of the test specimen Control Panel The Control Panel consists of a power pack complete with drive motor and an oil tank, control valves with to DIGITAL ELECTRONI

Country of Origin : India

Type : Universal Testing Machine, Front Open Hydraulic Gripping

Certification : Iso 9001:2008

Application : Testing

Weight : 5-10 Ton, 10000kg-1 Ton, 1000-10000kg, 100-1000kg, 100 Kg to 200 Ton (Up to 2000 kN))

Voltage : 440V

Automatic Grade : Fully Automatic, Automatic

Power : Hydraulic

Brand Name : Mechatronic Engineers

Warranty : 12 Months

...more

Brinell Hardness Testing Machine

1 Piece (MOQ)

Mechatronic Engineers make Hardness Testers Model B-3000(O) is precision-engineered to IS:2281- 1968, BS:240, and ASTM: E10. However, ME-B-3000 (O)PC is most suitable for production testing. This machine is designed to measure the hardness of casting, forgings, other metals, and alloys of all kinds, hard or soft, whether flat, round or irregular in shape. Available Models: Regular Computerized Machine Semi-automatic operation Fully Automatic Machine means loading/unloading and results will get automatically. The software: Facility for Auto/semi Auto / Manual modes of operation. Well managed database saves readings w.r.t. batch. Facility for calibration and check of calibration. Applications : To measure Rockwell Hardness directly on machine where presently Rockwell-Microscope is used. This avoids eye-straining of the operator on producing testing. In addition, it gives far better-repeated accuracy. High-low limits selections enables operator easy acceptance/rejection of components. Can be connected to a Laptop or Desktop PC. Easy to carry anywhere and handy for use with easy setup. Scope of Supply Machine containing CCD Camera, optics, and illumination systems with connecting cable. External Video capture with USB 2 connectivity and driver software. Rockwell Impression Measurement System (B.I.M.S.) software. PC or LAPTOP and windows XP operating systems is to be procured by the customer. One USB 2.0 and one RS232 (serial) interface (9 pins) is required and it is recommended for the Laptop to use an external USB to serial converter for the RS232 interface. Calibration Facility The systems include calibration and check facilities to calibrate the systems and for checking of calibration. This eliminates any system error in measurement. The range of Measurement is from 1 mm to 6 mm of diameter with a Resolution of 0.01 mm.

...more

Brinell Hardness Tester

1 Piece (MOQ)

Mechatronic Engineers make Hardness Testers Model ME-B-3000(O) is precision-engineered to IS:2281- 1968, BS:240, and ASTM: E10. However, ME-B-3000 (O) is most suitable for production testing. This machine is designed to measure the hardness of casting, forgings, other metals, and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

...more

Brinell Hardness Testing Machine

1 Piece (MOQ)

Mechatronic Engineers Testers Model ME-B-3000(J) is precision-engineered to IS:2281- 1968, BS:240 and ASTM: E10. However, ME-B-3000(J) is most suitable for production testing. These machines are designed to measure the hardness of casting, forgings, other metals and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

...more

Brinell Hardness Testing Machine

1 Piece (MOQ)

Mechatronic Engineers Testers Model ME-B-3000(H) is precision-engineered to IS:2281- 1968, BS:240 and ASTM: E10. However, ME-B-3000(H) is most suitable for production testing. These machines are designed to measure the hardness of casting, forgings, other metals and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

...more

Broaching Machine

1 Piece (MOQ)

U & V Notch : 2 mm, 3 mm, 5 mm || Simple Operation || Expensive Grinding Tools are not required

Automatic Grade : Automatic

...more

Long Travel Extensometer

1 Piece (MOQ)

Mechatronic Engineers’ Long Travel Extensometer Model ME-LT is used for testing high elongation material & stranded wires

Country of Origin : India

Application : Industrial Use

Feature : Durable

...more

Horizontal Chain and Rope Tensile Testing Machine

1 Piece (MOQ)

Features: The HorizontalTensile Chain and Rope Testing Machine incorporate design features to enable high accuracy testing with economy, speed, and versatility. Loading accuracy as high +/- 1 % as per Grade A of materials Fully customized Windows-based software for real-time graph & data processing with a wide range of data entry Motor-driven gear shaft for quick and effortless adjustment of test length to facilitate rapid fixing of test specimen High reading accuracy due to large size of the dial. Wide range of standard and special accessories, including load stabilizer. Large effective bed clearance enables testing of a wide range of specimens. Simple controls for ease of operation Robust straining frame of an extremely rigid construction. Safe operation ensured by means of safe devices. Fully automatic load & displacement digital panel Application: Horizontal Chain and Rope Tensile Testing Machine is designed to test chains and ropes under tension. Principle of Operation: Operation of the machine is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife-edges, which are prone to wear and damage due to shock on the rupture of test pieces. Load is applied by the hydrostatically lubricated piston. Main cylinder pressure is transmitted to the pressure cell housed in the control panel. The pressure transmitted to the pressure cell is directly convert pressure into load in kN shows absolute load applied on the test specimen digitally Rotary encoder is used to show displacement & it will display with load in the electronic panel. Machine consists of: Straining Unit: It consists of a hydraulic cylinder and a crosshead coupled to the piston rod of the hydraulic cylinder, mounted on to a robust base. The cylinder and the piston are individually lapped to eliminate friction. The crosshead is connected to two screwed columns and is driven by a motor for rapid adjustment of test length. The stationary crosshead is pinned to the loading frame. It can be pinned along the bed length in steps of 500 mm. All these crossheads are on wheels to reduce the friction while in motion. An elongation scale with a minimum of 1 mm is provided to measure the elongation of the specimen. CONTROL PANEL: The control panel consists of a power pack complete with drive motor and an oil tank, control valve, Pressure Transducer, Rotary Encoder, Digital indicator system Power Pack The unit generates a maximum pressure of 200 kgf/cm2. The hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulics Controls: Hand operated wheels are used to control flow to and from the hydraulic cylinder. The regulation of the oil is infinitely variable. Incorporated in the hydraulic system is a regulating valve. Which maintains a practically constant rate of crosshead movement. Load Displacement Indicator System: This is a microprocessor-based electronic panel which shows load & displacement digitally. It transfers all data to computer software with showing a real-time graph on our software… A overload trip switch is incorporated which automatically. Cuts out the pump motor when the load range in use in exceeded. Accuracy and Calibration: All Horizontal Tensile Chain and Rope Testing Machines are closely controlled for sensitivity accuracy and calibration during every stage of manufacture. Every Machine is than calibrated over of its chart ranges in accordance with the procedure laid down in British Standards 1610-1964 and IS: 1828-1975. Horizontal Chain and Rope Tensile Testing Machine comply with Grade “A” of BS: 1610-1964 and Grade 0.1 of IS: 1828-1975. An accuracy of + 1% is guaranteed from 20% of the load range selected to full load. Special Accessories: This includes load stabilizer, extra-long frames, and a wide range of accessories offered on request at additional cost. Installation: It is recommended that machines be erected on a foundation. Details on the foundation can be given on request. We reserve the rights of change in the above specifications due to constant improvement in design. The dimensions given are all approximate.

...more

Compression Testing Machine (Hand Operated / Manual)

1 Piece (MOQ)

Channel type Load Frame : In these load frames “C” channels are used, they are welded at the top as well as the bottom and withstand high loads. A hydraulic jack is fitted at the center of the base of the load frame, over which can be fitted lower platen and spacer block with help of centering pin. A lead screw passes through the top of the frame. To the lower end of this lead, the screw is fixed the upper platen with a spherical seat for self-alignment. The platens are accurately machined, hardened, and polished. The lower platen has concentric grooves to correctly place the specimen.

Country of Origin : India

Automatic Grade : Automatic

Warranty : 1year

...more

Fatigue Testing Machine

1 Piece (MOQ)

APPLICATION & OPERATIONS This machine is used to test the fatigue strength of materials and to draw an S-N diagram by the research institute, laboratories, material manufacturers, and various industries. This is a rotating beam type machine in which load is applied in a reversed bending fashion. The standard 8 mm dia specimen is held in special holders at its ends and located such that it experiences a uniform bending moment. The specimen is rotated at 4200 rpm by a motor. A complete cycle of reversed stresses in all fibers of the specimen is produced during each revolution. The bending moment is applied with the lever system and can be easily changed by moving a weight over the lever. Total number of revolutions at which the specimen fails is recorded by a mechanical counter. An interlocking system puts off the motor at specimen failure. The machine meets the requirement of IS 5075-1969. 6-digit electronic counter instead of the mechanical counter can be supplied at an additional price. Machine with maximum bending moment up to 400 Kg. cm can be offered on request. Features Table model, no need of foundation. Simple lever system for changing load. Calibration in Nm available on request. Lightweight, Simple design, Compact Size.

...more

Electronic Extensometer

1 Piece (MOQ)

Mechatronic Engineers offers electronic extensometer ME-EE 2 to measure material extension with a resolution of one micron. Strain gauge type extensometer is used up to the elastic limit to determine important parameters like 0.1%, 0.2% proof stress, and Young’s Modulus. This requires Mechatronic Engineer’s make Electronic Control Panel.

Feature : Durable

...more

Compression Testing Machine

1 Piece (MOQ)

Loading Frame The load frame is steel welded. It is designed to withstand a few million times of full cycles of loading without any sign of distortion or fatigue. These frames are light in weight. The base carries a fine finished hydraulic ram and the lower platen. The top plate has a spherical seating to take care of any irregularity of the specimen surface or slight misplacement of the specimen from the central axis. The front cover is made of an expanded sheet, which is provided as protection to the operator while at the same time giving an unobstructive view of the specimen under test. An additional frame is provided by the side of the main unit for testing of samples in flexure as per EN 196 is fixed on the left-hand side of the main loading unit Power Pack Powerpack is placed by the side of the loading unit and is connected to the main unit through quick-couplings. It is powered by a single-phase motor to load the unit to its maximum capacity. It has provision for fast lift and also for the selection between the compression unit or flexure unit. Specifications Digital Models Electrically Operated Analog Models Hand Operated The pumping unit is fitted with 1 Nos. of 20 cm dia Hydraulic Pressure Gauges Digital Display Unit for Digital Models Analog Dial for Analog Models With Calibration Certificate

Country of Origin : India

Application : Testing Material

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

Digital Torsion Testing Machine

1 Piece (MOQ)

Type : Torsion Testing Machines

Weight : 100-500kg

Color : Grey

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

...more

Retrofitting Services

onsite calibration services

Annual Maintenance Contract Services

Location : On-Site

Service Period : 1 Day

Opening Hours