Spring Testing Machine

Get Price Quote

1 Piece (MOQ)

Features Microcontroller Based Advanced System Unit Force Measurement Accuracy ± 1% of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick and Accurate Measurement Interchangeable Load Cells Simple Controls for Ease of Operation. Modulus Data for Load & Displacement (For Selectable Models with Software) Safe Operation Ensured by Means of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation with Drive & Motor Available

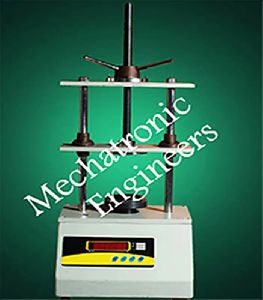

Digital Spring Testing Machine

35,000 - 900,000 Per Set

1 Set(s) (MOQ)

We are a reckoned Manufacturer and Supplier of Spring Testing Machine from Maharashtra, India. Our Testing Machine comprises of two hard chrome plated columns with fine cut single screw. Our Spring Testing Machine is widely used for quick and accurate testing of compression & tension test of springs. In order to meet bulk and immediate demands of the buyers, we maintain a huge stock in our spacious warehouse. One can purchase the Machine from us at nominal rates. Highlights : The machine comprise of two hard chrome plated columns with fine cut single screw with hand wheel for manual loading and unloading arrangement The machine uses a high precision Load Cell for measurement of force For displacement measurement Mechanical Linear Scale or Digital Vernier Caliper or Rotary Encoder is used Measuring System is based on latest microcontroller / microprocessor based electronic panels with all facilities Features : Microprocessor / Micro-controller Based Unit. Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher. Quick And Accurate Measurement. Interchangeable Load Cells. Modulus Data For Load & Displacement (For Selectable Models With Software). Simple Controls For Ease Of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional : Displacement Measuring Option : Mechanical Scale for Measuring Displacement. Digital Vernier with Resolution 0.01 Mm Encoder with Digital Readout 0.1 Mm Serial Interface On Demand. NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Best Deals from Spring Machine

Spring Testing Machine

45,000 - 560,000 Per Piece

1 Piece (MOQ)

INTRODUCTION Our range of Spring Testing Machines is widely used for quick and accurate testing of compression & tension test of springs. The machine comprise of two hard chrome plated columns with fine cut single screw with hand wheel for manual loading and unloading arrangement. The machine uses a high precision Load Cell for measurement of force. For displacement measurement Mechanical Linear Scale or Digital Vernier Caliper or Rotary Encoder is used. Measuring System is based on latest microcontroller / microprocessor based electronic panels with all facilities. FEATURES Microprocessor / Microcontroller Based Unit Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick And Accurate Measurement Interchangeable Load Cells Modulus Data For Load & Displacement (For Selectable Models With Software) Optional Dot Matrix Printer Interface Optional Windows Xp Based Software With Rs-232 Interface Simple Controls for Ease of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation With Drive & Motor Available OPTIONS Hydraulic Pump Operated Machine Digital Vernier Scale with 0.01 mm resolution for displacement measurement (6” or 12”) Rotary Encoder with separate digital unit with resolution 0.1 mm or 0.01mm 9 /24 pin Dot Matrix printer interface Serial RS-232 interface with windows

LSPM Leaf Spring Shot Blasting Machine

Get Price Quote

The first of its kind in the country with edge peening facility. The machine is equipped with auto sensing i.e., Whenever there is leaf on the conveyor the abrasive is ON Otherwise the abrasive is in OFF condition. The Leaf Spring Shot Peening Machine are so designed to give 90-100% coverage in a single pass. The machines have been designed to convey two springs in parallel. The machines are lined with hard cast material that are highly abrasive resistant.Special Features : Only loading / unloading manually. Rest all operation automatic with preset timer. Evenly peening operation within one pass with edge peening facility. Very high output. Low power consumption. Low operating cost. Low maintenance cost.

Spring Testing Machine

Get Price Quote

SHIVAMs Spring Testing Machines are used for quick and accurate testing of tension and compression springs. The Spring Testing Machine comprises of two hand-chrome plated columns with fine cut single screw and hand wheel for manual loading as well as unloading arrangement. Our Spring Testing Machine uses a high precision-load cell for measurement of force. For displacement measurement, mechanical linear scale or digital vernier caliper or rotary encoder is used. Measuring system of Spring Testing Machine is based on latest microprocessor based electronics with tare facility. We manufacture and supply Spring Testing Machine across the nation. Options Digital vernier scale with 0.01 mm resolution for displacement indication ( 6 to 12 ) Rotary encoder with separate digital unit 0.1 to 0.01 mm resolution 9 / 24 pin Dot Matrix printer interface Serial interface hardware with data transfer software to computer Motorized loading operation Features Microprocessor based unit. Force measurement accuracy + 1% of indicated load or 0.5% of full load value whichever is higher. Quick and accurate measurement Interchangeable load cells Modulus data for load and displacement Optional Dot Matrix Printer interface Optional RS 232 Computer interface with window based software

Spring Testing Machine

Get Price Quote

We are a reckoned Manufacturer and Supplier of Spring Testing Machine from Maharashtra, India. Our Testing Machine comprises of two hard chrome plated columns with fine cut single screw. Our Spring Testing Machine is widely used for quick and accurate testing of compression & tension test of springs. In order to meet bulk and immediate demands of the buyers, we maintain a huge stock in our spacious warehouse. One can purchase the Machine from us at nominal rates. Highlights : The machine comprise of two hard chrome plated columns with fine cut single screw with hand wheel for manual loading and unloading arrangement The machine uses a high precision Load Cell for measurement of force For displacement measurement Mechanical Linear Scale or Digital Vernier Caliper or Rotary Encoder is used Measuring System is based on latest microcontroller / microprocessor based electronic panels with all facilities Features : Microprocessor / Micro-controller Based Unit. Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher. Quick And Accurate Measurement. Interchangeable Load Cells. Modulus Data For Load & Displacement (For Selectable Models With Software). Simple Controls For Ease Of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Displacement Measuring Option : Mechanical Scale for Measuring Displacement. Digital Vernier with Resolution 0.01 Mm Encoder with Digital Readout 0.1 Mm Serial Interface On Demand.

spring testing machines

Get Price Quote

Digital Spring Testing Machine

Get Price Quote

Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick And Accurate Measurement Interchangeable Load Cells Modulus Data For Load & Displacement (For Selectable Models With Software) Optional Dot Matrix Printer Interface Optional Windows Xp Based Software With Rs-232 Interface Simple Controls For Ease Of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation With Drive & Motor Available

Leaf Spring Testing Machine

Get Price Quote

Precision accuracy, sturdy construction, cost effective, rust resistance are some of the key attributes that make our Spring Testing Machines special from other’s one. We are tagged as a prominent Manufacturer & Supplier of Spring Testing Machine based in Maharashtra, India. Assembled under the vigilance of professionals, offered product stands tall on the quality expectations. Spring Testing Machines are obtainable at the most reasonable prices.

Spring Testing Machine

Get Price Quote

We are one of the major Manufacturers, Exporters and Suppliers of Spring Testing Machines in Ichalkaranji (India). The Spring Testing Machines are used for quick and accurate testing of the various types of tension and compression springs. The Spring Testing Machines consist of two hard core plated columns that have a tine cut single screw. The Spring Testing Machines also have a hand wheel that is used for the manual loading and unloading of the components. The Spring Testing Machines make use of a high precision load. Apart from that, the mechanical linear scales, digital vernier calipers or rotary encoders are used in the Spring Testing Machines for the measurement of displacement. The Spring Testing Machines have a measuring system that is modeled on the modern microprocessor based electronics and comes with all kinds of facilities. Features Of Spring Testing Machines : Optional RS-232 Computer interface with window based softwareMicroprocessor based unitOptional dot matrix printer interfaceModulus data for load & displacementForce measurement accuracy W-1% of indicated load or 0.5% of full load value whichever is higherQuick and accurate measurementInterchangeable load cells Options For Spring Testing Machines : Motorized loading operationSerial interface hardware with data transfer software to computerRotary encoder with separate digital unit 0.1 or 0.01 mm resolution9/24 pin Dot-Matrix printer interfaceDigital vernier scale with 0.01 mm resolution for displacement Indication (6" or 12")

Spring Testing Machine

Get Price Quote

Precision accuracy, sturdy construction, cost effective, rust resistance are some of the key attributes that make our Spring Testing Machines special from other’s one. We are tagged as a prominent Manufacturer & Supplier of Spring Testing Machine based in Maharashtra, India. Assembled under the vigilance of professionals, offered product stands tall on the quality expectations. Spring Testing Machines are obtainable at the most reasonable prices.

spring testing machines

Get Price Quote

Good for testing laminated and coil springs. Load indication on large dial and deflection indication on electronic digital display with 0.1 mm least count. Autographic elongation recorder. Various models - Max load capacity from 6 to 50 Tone. Loading accuracy well within +- 1%

spring testing machines

Get Price Quote

Digital Spring Testing Machine

Get Price Quote

MCS range of spring testing machines are used for quick and accurate testing of tension and compression springs. The machine comprises of two hard crome plated cclomns with fine cut single screw with hand wheel for manual loading and unloading arrangement. The machine uses a high pricision load cell for measurement of force. For displacement measurement, mechanical linear scale or digital vernier caliper or rotary encoder is used. Measuring system of machine is based on latest microprocessor based electronics with tare facility.

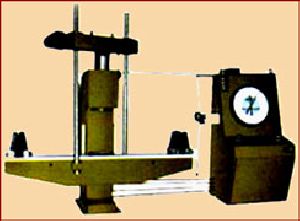

Laminated Spring Testing Machine

Get Price Quote

The FIE Spring Testing Machine, Models St and CST, incorporates design features to enable high accuracy testing with economy, speed and versatility • Loading Accuracy as high as + 1%• Four standard measuring ranges available with auto load-selector.• Deflection is read directly on electronic Electronic Digital Display.• Straining at variable speeds to suit a wide range of applications.• Autographic recorder supplied as standard to enable study of behavior of springs • Motorised drive for rapid adjustment of the height • High reading accuracy due to large size of dial.• Large effective test space enables testing of wide range of springs.• Robust staining frame of an extremely rigid construction.• Safe operation ensured be means of safety devices.• Fully enclosed and protected pendulum. Application : FIE Laminated Spring Testing Machine is designed to test Laminated Springs and Coil Springs under compression and bending loads. Principal of Operation : Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces.Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen.Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen. Machine consists of : Straining Unit : This consists of a "C" type rigid frame with hydraulic cylinder at its top and adjustable main testing tale is connected to an upper cross-head through two screwed columns can be rapidly adjusted to test height by means of motor. A pair of trolleys is provided on the table to take the horizontal deflection of the spring under loading. Laminated springs are tested by placing them on trolleys provided on the table. Coil Springs are tested by placing them between the compression plates. Hardness test can also be conducted with a suitable attachment. Control Panel : The control Panel consists of a power pack complete with drive motor and an oil tank, control valve a pendulum dynamometer a load and deflection indicating system and an autographic recorder. Power Pack : The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls : Hand operated wheels are used to control the flow to and from the hydraulic cylinder. The regulation in the oil is infinitely variable. Incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of table movement. Load and Deflection Indicator System : The load Indicator System consists of a large dial and a pointer. A dummy pointer is provided to register the maximum load reached during the test. Different measuring ranges can be selected by operating the range selection knob. An overload trip switch is incorporated which automatically cuts out the pump motor when the load range in use is exceeded.The deflection indicator system operates electronically and deflection is read directly on the digital display with least count of 0.1 mm. The encoder is mechanically coupled to the main hydraulic ram for getting signal of deflection. Pendulum Dynamometer : This unit permits selection of favorable hydraulic ratios producing relatively small frictional forces. Pressurised oil in the loading cylinder pushes up the measuring piston proportionately and actuates the special dynamometer system. The piston is constantly rotated to eliminate friction. The dynamometer system is also provided with special damper and ensures high reliability of operation. The load transmitted to the dynamometer is transferred through a pendulum to the load indicator. Autographic Elongation Recorder : This unit is of the pen and drum type and is supplied as standard. The horizontal motion of the pen produces the load ordinate of the diagram and the drum rotation produces the extension ordinates in the ratio of either 1:1 or 1:2. Accuracy & Calibration : AII FIE Laminated Spring Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in BS : 1610 : 1964FIE Spring Testing Machines comply with Grade "A" of BS : 1610 : 1964 and Grade 1.0 of IS 1828 : 1975 An accuracy of + 1.0% is guaranteed from 20% of the load range selected to full load. Helical Coil Spring Testing Machine Model CST : FIE's range also includes Helical Coil Spring Testing Machine, Model CST for testing coil springs under compression loads. the principle of operation, details on control panel, except deflection indicator system, accuracy and calibration are the same as the laminated Spring Testing Machine. Model ST described alongside. The straining unit is designed for coil Springs. It consists of a Hydraulic Cylinder and a table coupled with the ram of the hydraulic cylinder mounted on a robust base. The cylinder and the ram are individually lapped to eliminated friction. The cross-head is connected to two screwed columns and is driven by a motor for rapid adjustment of test height.

Spring Testing Machine

Get Price Quote

We are offering spring testing machine.