Brinell Hardness Testers - Fully Automatic Computerized

Get Price Quote

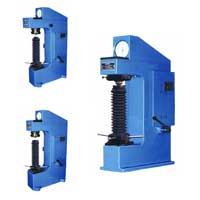

Digital Rockwell Hardness Tester

95,001 Per Piece

1 Piece (MOQ)

Being the foremost organization, we rule the market by offering an exclusive collection of Digital Rockwell Hardness Tester. The offered product is suitable for testing on Rockwell A, B, C scales. Apart from this, our hardness testers are ideal for test loads of 60, 100 and 150 KGS.

Best Deals from Testing Equipment

Vickers Hardness Tester

100,000 - 300,000 Per Piece

1 Piece (MOQ)

We offer vickers hardness tester. F e a t u r e s: testing range is very wide, from soft metal such as lead upto the hardest, like hardened steel. same hardness number is obtained on the same specimen, regardless of the load applied. the indentation is tiny and allows testing of precision finished parts loading and unloading cycle is motorised. built in projection screen to get accurate results. thin sheet metal can be perfectly tested as load applied is very small.

Vickers Hardness Tester

Get Price Quote

Pendulum Impact Tester (Model - IT 30 )

Get Price Quote

1 Piece (MOQ)

The pendulum Impact Tester, Model IT-30 is designed for conducting Izod, Charpy test. The test methods confirm to BS:131:PART 4-1972 (Amended 15 Aug. 1993) BSEN:10045-2:1993. The pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy the lower one for Izod testing. On release, the pendulum swings down to break the specimen & the energy absorbed in doing so is measured as the difference between the height of drop before rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on digital readout in case of electronic machines). There are two strikers and one combined support anvil available for fitting in to the pendulum and on the base of machine for the Izod, Charpy test respectively. Changing from one striker to another is achieved simply by fixing the new striker into it’s position. CHARPY TEST The Charpy test piece rests on alloy steel support anvils, fitted on the base of the machine rigidly held in position by Allen screws. End stopper is provided for quickly and accurately locating the test piece centrally between the supports. IZOD TEST The Izod Test piece is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the test piece in correct height with the help of Izod setting gauge supplied. Optional accessories Self centering tong for quick and accurate setting of Charpy test specimen ‘V’ notch milling cutter. Caliper gauge checking V notch for Izod & Charpy. ‘U’ notch milling cutter. Templates for checking 10x10mm. Cross section of Izod/Charpy test specimen. Depth notch gauge including V & U notch gauges for checking depth below V/U notch, angle and radius. Standard Accessories Izod Striker Charpy Striker Anvil Spanner Set Manual

Brinell Hardness Tester

Get Price Quote

1 Piece (MOQ)

Scratch Hardness Tester

Get Price Quote

Consists of Carbide tipped plough, dial indicator. Employees scratch type test to check bonding and hardness of cores. To find out the hardness of baked or dried cores made out of core sands, resin sands etc.

Aggregate Impact Testing Apparatus

Get Price Quote

We are a respected manufacturer, supplier and exporter of Aggregate Impact Testing Apparatus in Kolhapur, India. This is an important instrument in construction projects and fulfils many purposes of the industry. The apparatus offered by us is highly demanded due to its precise and effective working. We manufacture the testing apparatus in adherence to quality standards and norms of the industry. The apparatus is widely used in the ceramic industry and calibration laboratories or test houses. Specifications : Mechanical Properties of Aggregates RSI-185 Aggregate Impact Tester - IS 2386 (Part IV),BS812 Determining the aggregate impact value of coarse aggregate. Consists of a base weighing between 22-30 kg with a lower surface of not less than 30 cms and support columns to form a rigid frame work around quick release trigger mechanism to ensure an effective free fall of the hammer during test. The free fall can be adjusted through 380+-5.0 mm. The hammer is provided with a locking arrangement. A metal tup (hammer) weighing 13.5 to 14.0 kg, the lower end of in cylindrical shape, 100 mm in diameter and 5 cm long with a 2 mm chamfer I at the lower edge, and^ case hardened. Complete with a cylindrical cup, 102 mm dia x 50 mm depth, one measure 75mm dia x 50 mm deep and tamping rod of circular cross-section 10 mm in diameter and 230 mm long, rounded at one end. RSI-186 Aggregate Impact Tester with automatic blow counter, as per IS - 2386 (P-IV) Spares Automatic blow counter Tamping rod. RSI-187 Aggregate Crushing Value test apparatus : IS : 2386 (Part IV) Consists of a 15 cms diameter open-ended steel cylinder, with plunger and base plate. Complete with a tamping rod of circular cross-section 16 mm in diameter and 45 to 60 cms long, rounded at one end. RSI-18810% Fine Value apparatus as per IS: 2386 (p-iv) with tamping rod and measure. RSI-189 Aggregate Crushing Value test apparatus IS:2386(P-iv)BS812 Similar to RSI-187, but 75 mm dia cylinder. Accessories : Cylindrical metal measure 11.5 cms diameter and 18 cms height fitted with handles. Aggregate Abrasion Value RSI-190 Deval Abrasion Testing machine: IS: 2386 (P-IV) For the determination of resistance of aggregate to wear by abrasion. Two hollow cylinders, closed at one end and provided with tightly fitting covers at the other end. The inside diameter of the cylinder 20 cms and 34 cms depth. The cylinder are mounted on a shaft at an angle of 30 degrees with the axis of rotation. The shaft rotates at 30-33 r.p.m. through a reduction gear, coupled to a motor. Suitable for operation on 440 volts, three phase, 50 cycles,A.C. Supply. Supplied complete fitting with a counter and push button starter. Accessories Abrasive Charge - Consists of 12 Nos. cast iron spheres or steel spheres (steel balls) hardened, approximately 48 mm in diameter, each weighing between 390-445 gram.

RASN-M Hardness Testers

Get Price Quote

1 NOS Piece (MOQ)

In case of 'RASN' series machines for Rockwell & Rockwell superficial tests a preliminary test force in first applied and then indicator is automatically set for zero. Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator. Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell hardness number.

control panels instruments

Get Price Quote

We can supply Signal Isolators, DC Dc Convertors, Panel Accessories such as Fans, Filters, Thermostats, climate control units, Relay Modules , Cable and cable accessories

Brinell Hardness Tester

Get Price Quote

Vickers Hardness Tester

Get Price Quote

we offer vickers hardness tester that is suitable to be used for testing various products & raw materials. This computerised vickers hardness tester model: model vm 50 pc is reckoned for its state-of-the-art features, thus, has great market demand. We offer the vickers hardness tester to the clients at reasonable price. specifications vickers hardness tester model : vm – 50 pcbuilt in projection screen to get accurate resultstests loads : 5, 10, 20, 30 & 50 kgf.scale least count 0.001 mm features fully computerised (pc based) vickers hardness machinedirect and accurate measurement of vickers hardness number using "state of art" image processing technologywide testing range' : from soft metal such as lead up to medium hardened steelshigh accuracy and repeatability of measurement at all loadsfaster measurement yielding to higher productivitysmall size of indentation makes it a non destructive testing on finished components motorised loading and unloading cyclesmall loads allow testing of thin sheet metalsadvanced window xp based software latest gui features user friendly software with all help file and window features online indentation setting and focusing on pc monitoradvance image processing : algorithms implemented for precise calculation of hardness numbers with various options to cover all ranges of specimen

Electronic Extensometer Tester

Get Price Quote

We are offering our client an excellent quality range of Electronic Extensometer Tester. These Electronic Extensometer are made from very high quality raw material which ensures high durability at its user end. These Electronic Extensometer are in high demand in the market. Different sizes and designs are easily available in the market. Our Electronic Extensometer are available at industrial leading prices.

Optical Brinell Hardness Tester

126,000 - 180,000 Per Piece

Rockwell Hardness Tester

Get Price Quote

Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. Test Force Selection by external dialing.

Rockwell Hardness Tester

Get Price Quote

Digital Hardness Tester for Rockwell Tests has motorized automatic cycle operation i.e. loaddwellunload. The Preliminary Test Force is 98.07N (10kgf). Total Test Force is 588.4, 980.7, 1471N (60,100,150 kgf). Test Force Selection is by external mechanical dial. The system has bar indication on display for Preload. User can set Preload Dwell time, Dwell time for Total Load and Elastic recovery Dwell time. The operation is easy with keyboard entry through reliable membrane switches for scaleHI-GO-LODwell time selection. The scale display is with 0.1 Rockwell Resolution. The system has real time measurement with Digital Dial Indicator of 1 micron resolution. The machine has feature of data export to PC or serial printer. It gives results indicating serial number of tests, hardness scale, hardness value and high good low indication w.r.t limits entered. The Digital Rockwell Hardness Tester (MCS-RASNE) covers Rockwell scale A, B, C, D, E, F, G, H, K, L, M, P, R, S, V and confirms IS : 3804, BS 10109-2 & ASTM E-18. The Digital Rockwell Superficial Hardness Tester (MCS-RASNES) includes all Rockwell scales and 15T, 30T, 45T, 15N, 30N, 45N, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y and confirms IS : 5073, BS 10189-2 & ASTM E-18

Digital Rockwell Hardness Tester

150,000 Per Piece

1 Piece (MOQ)

ABT Meter

72,000 Per Piece

Computerized Brinell Hardness Tester

Get Price Quote

We are a proficient manufacturer, exporter and supplier of computerized brinell hardness tester model no. - kb-3000 (o) from mumbai, india. Our model 2 kb-3000 (0) is an electrically operated hardness testing machine, which is suitable for mass testing of components made of steel and other materials whether flat or round. Our computerized brinell hardness tester model no. - kb-3000 (o) is accessible at very reasonable prices.

tensile testing equipment

Get Price Quote

Proving our dominance in material testing machines domain, we have formed tie-ups with reputed and prestigious organizations, defense labs, research institutes, metallurgical labs, engineering colleges and steel industries in India and abroad.