Universal Tensile Testing Machine

500,000 - 1,000,000 Per Piece

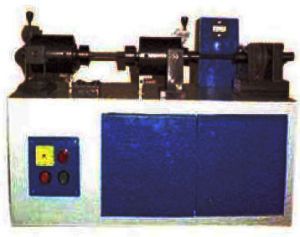

UTM-20 Mechanical Universal Testing Machine

Get Price Quote

1 piece (MOQ)

Best Deals from Testing Machines

Analogue Cum Computerized Universal Testing Machine

350,000 - 1,800,000 Per

1 Set(s) (MOQ)

SSS Make Analog Cum Computerised Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted.Principal of OperationOperation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen.Electronic Control Panel The electronic control panel is built using microprocessor which incorporates state of the art technology with following features : Front panel membrane type key board for test setup. 7 seg digital display of load displacement / extension. Printer port interface Serial port for communication with Pc. Optional add-on facility for electronic extensometers & electronic load pacer Storage of important parameters such as peak load, displacement at peak load & maximum displacement alter test. Period selection to take care of initial slippage Serial Communication & Software Package On PCThe SSS-UTM(M)(E) series control panel can be hooked to any PC using RS-232 communication port. offers different exhaustive application. Window based software packages on PC to enable the user to effectively evaluate different parameters.The features include : User friendly main menu with pop up menus prompt messages and help windows. Extensive graphics on screen for curve plotting, magnification and zooming. Evaluation of wide range of user selectable parameters such as young's modulus. yield stress. proof stress etc. Advanced file handling for data storage. Printout option for reports. data and graph etc. Optional software package for statistical evaluation. NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Fatigue Testing Machine

Get Price Quote

Fatigue Testing Machine we offer is extensively used in research institute, laboratories, and also supplied to material manufacturers and diverse industries. We make available the Fatigue Testing Machine which is Table model that does not require a foundation. The Fatigue Testing Machine we offer is light weight, simple in design and high performing. Components & Working Of Impact Testing Machine The rotating beam type machine in which load is applied in reversed bending fashion The standard 8 mm diameter specimen is held in special holders at its ends and located such that it experiences a uniform bending moment The specimen is rotated at 4200 rpm by a motor A complete cycle of reversed stresses in all fibers of the specimen is generated during each revolution The bending moment is applied with the lever system and can be easily changed by moving a weight over the lever Total number of revolution at which the specimen fails is recorded by a mechanical counter An interlocking system puts off the motor at specimen failure Machine meets requirement of IS 5075-1969 Standards 6 digit electronic counters instead of mechanical counter is offered Machine with maximum bending moment upto 400 Kg. cm is also available Fixed with simple lever system for changing load Calibration in Nm also offered Used To Test the fatigue strength of materials Draw S-N diagram

Spring Testing Machine

45,000 - 560,000 Per Piece

1 Piece (MOQ)

INTRODUCTION Our range of Spring Testing Machines is widely used for quick and accurate testing of compression & tension test of springs. The machine comprise of two hard chrome plated columns with fine cut single screw with hand wheel for manual loading and unloading arrangement. The machine uses a high precision Load Cell for measurement of force. For displacement measurement Mechanical Linear Scale or Digital Vernier Caliper or Rotary Encoder is used. Measuring System is based on latest microcontroller / microprocessor based electronic panels with all facilities. FEATURES Microprocessor / Microcontroller Based Unit Force Measurement Accuracy ± 1% Of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick And Accurate Measurement Interchangeable Load Cells Modulus Data For Load & Displacement (For Selectable Models With Software) Optional Dot Matrix Printer Interface Optional Windows Xp Based Software With Rs-232 Interface Simple Controls for Ease of Operation. Safe Operation Ensured By Means Of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation With Drive & Motor Available OPTIONS Hydraulic Pump Operated Machine Digital Vernier Scale with 0.01 mm resolution for displacement measurement (6” or 12”) Rotary Encoder with separate digital unit with resolution 0.1 mm or 0.01mm 9 /24 pin Dot Matrix printer interface Serial RS-232 interface with windows

H Brinell Hardness Testing Machine

Get Price Quote

Machine Designed With a Hydraulic Power pack and control circuit for effortless loading unloading opertations . A dial gauge in front measure depth of ball penetration. This facilities production testing with tolerance limits by compression Method

Erichsen Testing Machine

Get Price Quote

we are engaged in providing high quality erichsen testing machine to our esteemed clients. These erichsen testing machines are fabricated from high-grade components and advanced technology, which enhances their performance largely. The clients can avail the erichsen testing machine from us in assorted technical specifications. The erichsen testing machine is available at highly affordable price. specifications suitable for cupping tests on sheet metals having thickness from 0.1 to 2 mmleast count of measuring : 0.01 mmtable mounting modelnet weight approx : 20 kg

Brinell Hardness Testing Machine

Get Price Quote

We are into manufacturing as well as supplying of Brinell Hardness Testing Machine in India. Our Brinell Hardness Testing Machine is available in different models namely SHI B 3000 J, SHI B 3000 H and SHI B 3000 O. Brinell Hardness Testing Machine is quite appraised for ease of operation and low maintenance.

Mechanical Universal Testing Machine

Get Price Quote

The company has come up as a highly acclaimed Manufacturer, Exporter & Supplier of Mechanical Universal Testing Machine. The high quality Mechanical Universal Testing Machine is designed to perfection and is based on the client specifications. The accurate functioning of the Mechanical Universal Testing Machines, as well as their versatility, has made them popular across the globe. Application : Performs tensile, compression, bending and shear tests on metal & other materials, both in the form of test pieces and as finished products Features Continuous roll auto graphic recorder supplied as standard to enable study of the behavior of materialsHigh reading accuracy due to large size and design of dialEasy change from plain to threaded and screwed specimensRobust Straining frame of an extremely rigid constructionMotor driven threaded columns for quick effortless adjustment of lower cross head to facilitate rapid fixing of test specimenSimple controls for ease of operationSafe operation ensured by means of safety devicesFully enclosed & protected pendulumLoading accuracy as high as + 1 %Wide range of standard and special accessories, including load stabilizerLarge effective clearance between columns enables testing of standard specimens as well as structures Principle of Operation Operation of the machine is by hydraulic transmission of load from test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers & knife edges, which are prone to wear & damage due to shock onrupture of test pieces. Load is applied by a hydrostatically lubricated ram. The oil pressure in the main cylinder is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The dynamometer piston exerts a force proportionate to the hydraulic pressure. This force is transferred through a leverage system to a pendulum. Displacement of pendulum actuates the rack and pinion mechanism which operates the load indicating pointer. Return movement of pendulum is effectively damped to absorb energy in the event of sudden breakage of specimen.

RASN- Series Hardness Testing Machine

Get Price Quote

1 NOS piece (MOQ)

Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell hardness number.

Vickers Hardness Testing Machine Computerized

Get Price Quote

1 Piece (MOQ)

Features Fully Computerized (PC Based) Vickers Hardness Machine. Direct and accurate measurement of Vickers Hardness Number using “State of Art” image processing technology. ‘Wide testing range: from soft metal such as the lead up to medium hardened steels. High accuracy and repeatability of measurement at all loads. Faster measurement yielding to higher productivity. The small size of indentation makes non-destructive testing on finished components. Motorized loading and unloading cycle. Small loads allow the testing of thin sheet metals. Advanced Window XP based software. Latest GUI Features: User-friendly software with all help files and Window Features. Online indentation setting and focusing on the PC monitor. Advance image processing Algorithms implemented for a precise calculation of hardness numbers with various options to cover all ranges of specimens. Batch file Processing : Option for data/storage and reports generation. Statistical Evaluation: Software for calculating standard deviation, mode medium, histogram, etc. Options in calibration mode: Calibration / Verification on PC monitor makes it easier to operate. Computerized Vickers Hardness Tester is a simple and accurate means to produce automatically measure the diamond indentation to give Vickers hardness numbers. These testers are suitable for measuring the hardness of precision metallic parts with a wide testing range – from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS 1754 – 2002. Construction To accommodate the high precision loading system & an optical projection screen, the machine frame is designed sturdy. The specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied to a diamond penetrator by means of a lever & weights. The load is removed automatically after a specific lapse of time. The objective is indexed with the test piece & the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

Fatigue Testing Machines - AI

Get Price Quote

We are Manufacturer, Supplier, Exporter of all our product range and our setup is situated in Kolhapur ( Maharashtra, India ) Application Fatigue Testing Machines are used to test the fatigue strength of materials and to draw S-N diagram by Research Institution Laboratories, Material manufacturers, and various industries. Models : AI-FTM8 Accuracy & Calibration This machine conforms to requirement of IS : 5075 - 1969 Standards Salient Features An interlocking system provided puts off the motor at specimen failure Light weight, compact size and very simple design Table model, no need of foundation Simple lever system of changing load Calibration is in Nm

Digital Brinell Hardness Testing Machine

270,000 Per Piece

Analogue Cum Computerized Universal Testing Machine

Get Price Quote

MTMS Make Analog Cum Computerised Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted.Principal of Operation : Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen.Electronic Control Panel : The electronic control panel is built using 8085 microprocessor which incorporates state of the art technology with following features : Front panel membrane type key board for test setup. 7 seg digital display of load displacement / extension. Printer port interface Serial port for communication with Pc. Optional add-on facility for electronic extensometers & electronic load pacer Storage of important parameters such as peak load, displacement at peak load & maximum displacement alter test. Period selection to take care of initial slippage Serial Communication & Software Package On Pc : The MTMS-UTME series control panel can be hooked to any PC using RS-232 communication port. offers different exhaustive application. Window based software packages on PC to enable the user to effectively evaluate different parameters.The features include : User friendly main menu with pop up menus prompt messages and help windows. Extensive graphics on screen for curve plotting, magnification and zooming. Evaluation of wide range of user selectable parameters such as young's modulus. yield stress. proof stress etc. Advanced file handling for data storage. Printout option for reports. data and graph etc. Optional software package for statistical evaluation. Custom built application software to suit customer requirements

Concrete Compression Testing Machine

Get Price Quote

We are regarded as the leading manufacturer, exporter and supplier of Concrete Compression Testing Machine in Kolhapur, India. The offered machine is available in both manual and electrical configuration. The machine has high stability and durability. They are designed keeping in mind quality standards and norms. The machines can be availed from in various dimensions as per the specification of the client. Specifications : RSI-095 Compression Testing Machine, hand operated, 2000 Kn (200 tonne), Channel Model: Fitted with double plunger pump and hydraulic Load gauge 0-2000 KN cap RSI-096 Compression Testing Machine, hand operated, 2000 KN (200 tonne), 2 or 4 Pillar model, with separate pumping unit connected by a copper/rubber hose pipe, double plunger with pressure gauge 0-2000 KN capacity. RSI-097 Compression Testing Machine, 250 KN (25 tonne) Electrically-cum-manually operated. Two Four/Pillar Model. " Compression Testing Machine, 500 KN (50 tonne) Electrically-cum-manually operated. RSI-099 Compression Testing Machine, 1000 KN (100 tonne) cap. Electrically-cum-manually operated. 2 or 4 Pillaar Model RSI-100 Compression Testing Machine, 1000 KN (100 Tonne)cap. Electrically-cum manually operated. 2 or 4 Pillar Model : with two pressure gauges i.e. 0-500 KN x 2.5 KN divn. and 0-1000 KN x 5 KN/ divn. RSI-101 Compression Testing Machine, 2000 KN (200 Tonne) cap. Electrically-cum-manually operated. 2 or 4 pillar model. RSI-102 Compression Testing Machine, 2000 KN. (200 tonne) cap., Electrically-cum-manually operated with two Load gauges 2 or 4 Pillar Model. 0-1000 KN x 5 KN/divn. and 0-200KN x 10 KN/divn. RSI-103 Compression Testing Machine, 2000 KN (200 tonne) cap., Electrically-cum-manually operate with 3gauges. 2 or 4 Pillar MODEL. 0-500 KN x 2.5 KN, 0-1000 KN x 5 KN/div. and 0-2000 KN x 10 KN/divn. RSI-104 Compression testing Machine. Digital 2000 KN x 1 KN least count. RSI series Compression Testing machine are the finest of there type obtainable. The rugged construction & extreme simplicity make it possible for even non-technical personnel to operate them with ease and complete dependability. RSI Compression Testing Machine conform to the requirements international Standards like BS ASTM & Indian Standard IS:516. Some Salient Features : High Stability, Self Aligning Platen Suitable for Testing Cubes and Cylinders of various sizes, Brick can also be tested, Digital having function of peak hold facility, memory status, automatic cutoff of maximum Load, Alarm generated when the sample breaks down, Cubes of size 50 mm - 200 mm can be tested, Cylinders 100 mm x 200 mm ht.& 150 mm dia. x 300 mm ht. can be tested. Note : You can get Digital Readouts in all Machines cap. 250 KN to 3000 KN.

Analog Torsion Testing Machine

Get Price Quote

1 Piece (MOQ)

Shri ram industries offer torsion testing machine (sri tt 10), which are designed to check torsional property of various metal wires, tubes and bars. Further, we also calibrate these machines as per the latest and relevant industry standards.

vickers hardness testing machines

Get Price Quote

Universal Testing Machine

Get Price Quote

We are proud to offer superior quality Universal Testing Machines that are made in accordance with stringent international standards. The extra ordinary testing capacity of our testing machine makes us the best universal testing machine manufacturers and suppliers from Ichalkaranji, Maharashtra. Attributes Made from superior quality raw materials Exceptional quality High testing capacity Applications Engineering firms Construction industry Oil & Gas sector Model : SKI - UTM 10, SKI - UTM 20, SKI - UTM 40, SKI - UTM 60 & SKI - UTM 100

Vickers Hardness Testing Machine

Get Price Quote

Digital Rockwell Hardness Testing Machine

Get Price Quote

Digital Hardness Tester for Rockwell Tests has motorized automatic cycle operation i.e. loaddwellunload. The Preliminary Test Force is 98.07N (10kgf). Total Test Force is 588.4, 980.7, 1471N (60,100,150 kgf). Test Force Selection is by external mechanical dial. The system has bar indication on display for Preload. User can set Preload Dwell time, Dwell time for Total Load and Elastic recovery Dwell time. The operation is easy with keyboard entry through reliable membrane switches for scaleHI-GO-LODwell time selection. The scale display is with 0.1 Rockwell Resolution.

Horizontal Chain Rope Testing Machines

Get Price Quote

We offer premium quality Horizontal Chain Rope Testing Machines that is made keeping in mind the needs of the customers. It is made by the use of advanced technology that ensures its better functioning. Model : Mech.CS.CR Features : Real time graph & data processing with wide range of data entry owing to fully customized windows XP based softwareMotor driven gear shaft for quick and effortless adjustment of test length to facilitate rapid fixing of test specimen High reading accuracy due to large size of dial.Easy operation due to simple controlsRobust straining frame ensures extremely rigid constructionSafely devices for safe operationThe Horizontal Chain and Rope Tensile Testing Machine incorporate design features to enable high accuracy testing with economy, speed and versatility.Loading accuracy:+/- 1 %Fully automatic load & displacement digital panelWide range of standard and special accessories, including load stabilizer.Large effective bed clearance enables testing of a wide range of specimens. PRINCIPLE OF OPERATION : The machine operates by hydraulic transmission of load from the test specimen to a separately housed load indicator. The ones which are prone to wear and damage due to shock on rupture of test pieces are replaced by the transmission of load through levers and knife-edges. Hydrostatically lubricated piston applies the load. A main cylinder pressure is transmitted in the control panel to the pressure cell housed that directly converts pressure into load. KN shows absolute load applied on the test specimen digitally and rotary encoder shows displacement to display load in electronic panel. Machine Consists of : Straining unitControl panelPower PackHydraulics ControlsLoad Displacement Indicator System Special Accessories : Load stabilizerExtra long framesWide range of accessories offered on request at additional cost Click Here For More Detail

Fatigue Testing Machine

Get Price Quote

The company is one of the major Manufacturers, Exporters and Suppliers of Fatigue Testing Machines in Ichalkaranji (India). The Fatigue Testing Machines prevent one of the major reasons behind the failure of the materials used in engineering sector. The Fatigue Testing Machines provide details about the fatigue properties of the different materials so that they can be used in the proper applications in accordance with the detail provided. The AI-FT series Fatigue Testing Machines are used for various processes like measuring the fatigue strength that provides assistance in the drawing of S-N diagram. The Fatigue Testing Machines are widely used by research institutes, auto industries and various manufacturers. Working Of Fatigue Testing Machines : Rotating beam type machine where load is applied in reverse bending mannerStandard 8 mm diameter specimen held in special holders at the ends and loadedLoading is done in a way that a uniform bending moment is experiencedSpecimen is rotated at 4200 RPM by a motor Highlights Of Fatigue Testing Machine : Light weightCompact sizeSimple designTable model with no need of foundationSimple lever systems for changing loadAccurately calibrated as per IS 5075Can be supplied with Nm calibration on request

Mechanical Universal Testing Machines

Get Price Quote

Loading Accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for easy of operation. Robust staining frame of an extremely rigid construction. Safe operation ensured be means of safety devices. Fully enclosed and protected pendulum. Application : FIE Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted. Principal of Operation : Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen. Machine consists of : Straining Unit This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured be reveling the cylinder and ram of of any possible side loading by the provision of ball seatings. An elongation scale with a minimum graduation of 1 mm, is provided to measure the deformation of the specimen. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads, Compression, transverse, bending, shear and hardness tests are conducted between the lower cross head and the table. The lower cross-head can be raised or lowered rapidly by operating the screwed columns thus facilitating ease of fixing of the test specimen. Control Panel : The control Panel consists of a power pack complete with drive motor and an oil tank, control valves a pendulum dynamometer a load indicator system and an autographic recorder. Power Pack : The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls : Hand operates wheels are used to control the flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken. Load Indicator System : This system consists of a large dial and a pointer. A dummy pointer is provided to register the maximum load reached during the test. Different measuring ranges can be selected by operating the range selection knob. An overload trip switch is incorporated which automatically cuts out the pump motor when the load range in use is exceeded. Pendulum Dynamometer : This unit permits selection of favorable hydraulic ratios producing relatively small frictional forces. Pressurised oil in the loading cylinder pushes up the measuring piston proportionately and actuates the special dynamometer system. The piston is constantly rotated to eliminate friction. The dynamometer system is also provided with an integral damper and ensures high reliability of operation. The load transmitted to the dynamometer is transferred through a pendulum to the load indicator. Autographic Continuous Roll Load-Elongation Recorder : This unit is of the pen and drum type and is supplied as standard. The horizontal motion of the pen produces the load ordinate of the diagram and the drum rotation produces the extension ordinates in the ration of either 1:5 or 1:10. Accuracy & Calibration : AII FIE Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in BS : 1610 : Part 1 :1992 and IS 1828 : (Part 1) : 1991. FIE Universal Testing Machines comply with Grade "A" of BS : 1610 : Part 1:1992 and class 1 of IS 1828 : (Part1) : 1991 An accuracy of + 1.0% is guaranteed from 20% from 20% of the load range selected to full load. Below 20% of the selected range, the maximum permissible error is 0.2% of the full load reading.

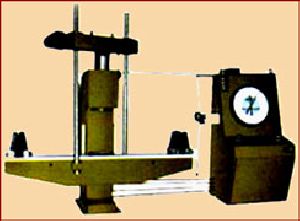

Laminated Spring Testing Machine

Get Price Quote

The FIE Spring Testing Machine, Models St and CST, incorporates design features to enable high accuracy testing with economy, speed and versatility • Loading Accuracy as high as + 1%• Four standard measuring ranges available with auto load-selector.• Deflection is read directly on electronic Electronic Digital Display.• Straining at variable speeds to suit a wide range of applications.• Autographic recorder supplied as standard to enable study of behavior of springs • Motorised drive for rapid adjustment of the height • High reading accuracy due to large size of dial.• Large effective test space enables testing of wide range of springs.• Robust staining frame of an extremely rigid construction.• Safe operation ensured be means of safety devices.• Fully enclosed and protected pendulum. Application : FIE Laminated Spring Testing Machine is designed to test Laminated Springs and Coil Springs under compression and bending loads. Principal of Operation : Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces.Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen.Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen. Machine consists of : Straining Unit : This consists of a "C" type rigid frame with hydraulic cylinder at its top and adjustable main testing tale is connected to an upper cross-head through two screwed columns can be rapidly adjusted to test height by means of motor. A pair of trolleys is provided on the table to take the horizontal deflection of the spring under loading. Laminated springs are tested by placing them on trolleys provided on the table. Coil Springs are tested by placing them between the compression plates. Hardness test can also be conducted with a suitable attachment. Control Panel : The control Panel consists of a power pack complete with drive motor and an oil tank, control valve a pendulum dynamometer a load and deflection indicating system and an autographic recorder. Power Pack : The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth. Hydraulic Controls : Hand operated wheels are used to control the flow to and from the hydraulic cylinder. The regulation in the oil is infinitely variable. Incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of table movement. Load and Deflection Indicator System : The load Indicator System consists of a large dial and a pointer. A dummy pointer is provided to register the maximum load reached during the test. Different measuring ranges can be selected by operating the range selection knob. An overload trip switch is incorporated which automatically cuts out the pump motor when the load range in use is exceeded.The deflection indicator system operates electronically and deflection is read directly on the digital display with least count of 0.1 mm. The encoder is mechanically coupled to the main hydraulic ram for getting signal of deflection. Pendulum Dynamometer : This unit permits selection of favorable hydraulic ratios producing relatively small frictional forces. Pressurised oil in the loading cylinder pushes up the measuring piston proportionately and actuates the special dynamometer system. The piston is constantly rotated to eliminate friction. The dynamometer system is also provided with special damper and ensures high reliability of operation. The load transmitted to the dynamometer is transferred through a pendulum to the load indicator. Autographic Elongation Recorder : This unit is of the pen and drum type and is supplied as standard. The horizontal motion of the pen produces the load ordinate of the diagram and the drum rotation produces the extension ordinates in the ratio of either 1:1 or 1:2. Accuracy & Calibration : AII FIE Laminated Spring Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in BS : 1610 : 1964FIE Spring Testing Machines comply with Grade "A" of BS : 1610 : 1964 and Grade 1.0 of IS 1828 : 1975 An accuracy of + 1.0% is guaranteed from 20% of the load range selected to full load. Helical Coil Spring Testing Machine Model CST : FIE's range also includes Helical Coil Spring Testing Machine, Model CST for testing coil springs under compression loads. the principle of operation, details on control panel, except deflection indicator system, accuracy and calibration are the same as the laminated Spring Testing Machine. Model ST described alongside. The straining unit is designed for coil Springs. It consists of a Hydraulic Cylinder and a table coupled with the ram of the hydraulic cylinder mounted on a robust base. The cylinder and the ram are individually lapped to eliminated friction. The cross-head is connected to two screwed columns and is driven by a motor for rapid adjustment of test height.

Computerized Universal Testing Machine

1,000,000 Per Piece

Spring Testing Machine

Get Price Quote

Precision accuracy, sturdy construction, cost effective, rust resistance are some of the key attributes that make our Spring Testing Machines special from other’s one. We are tagged as a prominent Manufacturer & Supplier of Spring Testing Machine based in Maharashtra, India. Assembled under the vigilance of professionals, offered product stands tall on the quality expectations. Spring Testing Machines are obtainable at the most reasonable prices.

tensile testing machines

Get Price Quote

Capacity 0.5 kN - 60 kN Mechanical, Electronic & Computerized versions available Useful for testing various materials like metals, springs, rubber, polymers, etc. Customized holding fixtures available

Compression Testing Machine

Get Price Quote

We are listed among the foremost Compression Testing Machines Suppliers based in Maharashtra. We offer superior quality Compression Testing Machines that are equipped with wear resistant spares and latest technology which makes them the best available option in the market. Complies To Indian Standards Specification 516-1959 Test Cube Size 5cm x 5cm x 5cm7.06cm x 7.06cm x 7.06cm10cm x 10cm x 10cm15cm x 15cm Test Concrete Cylinders 10 x 20cm15 x 30 cm

impact testing machines

Get Price Quote

it - 30 - suitable for izod and charpy tests as per is-1598, 1757, 1499 & 3766 and bs:131 parts 1, 2, 3 & 4. mit-1.4- suitable for izod tests on non-ferrous metals. Plastic materials, frp etc. mit-0.42- suitable for izod tests on plastic, wooden frp, glass, ceramic specimen and check adhesive property of bounded material etc. various models - max load capacity from 6 to 50 tone. loading accuracy well within +- 1%