Automatic Vibrator

Get Price Quote

Our products are the preferred choice of many, as they are grade assured and as per international quality management systems. The raw material that is used for manufacturing superior grade products is sourced from the reliable places after complete quality confirmation. The Automatic Vibrators we offer has a special feature of auto turn off after the use of 15 minutes.

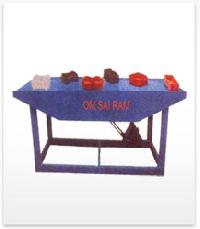

mould vibrating machine

Get Price Quote

We are the largest manufacturer, exporter and supplier of Mould Vibrating Machine in Kolhapur, India. The vibrator offered by us is mounted over coiled springs. The vibrations are developed by way of a revolving eccentric shaft. They are designed as per the quality standards using the latest technology. The simple design ensures easy assembly and dismantling of the cube moulds. We make sure that only quality approved mould vibrating machine reach the customers. Specifications : Heat of Hydration RSI-152 Calorimeter : IS : 4031, BS 4550,ASTM C186for Heat of hydration of Cement. Consists of : A open mouthed thermos flask, Beckman Thermometer, Insulating material, Container, Hinge, Stirring Motor, thermometer support, Glass stirring rod, Cork stopper, Reading Lens and glass Funnel. Vibrating Machine - IS: 10080, BS 4550 Consists of a frame mounted on coil springs to carry the cube mould , and a revolving shaft provided with an eccentric. By means of a balance weight beneath the base plate attached rigidly to the frame, the center of gravity of the whole machine, including the cube and mould, is brought either to the eccentric shaft, or within a distance 25mm below it. Normal running speed of eccentric shaft is 12,000±400RPM. Fitted with BELT GUARD. The motor and a crowned pully on the vibration machine. Supplied complete with one cube mould 7.06 cms with base plate. Suitable for operation on 230 V, single phase, 50 cycle, A.C. supply Complete with timer. RSI-153 : Vibrating machine with Digital timer. RSI-154 Pocking rod. Spares Belt Set of Springs Belt guard Cube Mould, steel 7.06 cms with base plate Time switch 0-5 minute.

Best Deals from Vibrating Machine

Vibratory Feeder Machine

Get Price Quote

Vibrating Knock Out Machine

Get Price Quote

Vibrating knockout machine is rigid in construction to sustain and to transmit the vibration to the molding box. Vibration is by electric motor through belt drive or by VIBROMETER. Vibration is controlled by unbalanced weights provided on each side of spindle.

Vibrating Knock Out Machine

Get Price Quote

We ARE MANUFACTURES AND SUPPLIER OF BEST QUALITY VIBRATING KNOCK OUT MACHINE AS PER CUSTOMER REQUIREMENT

Vibrating Knockout

Get Price Quote

Ganesh vibrating knockout machine is rigid in construction to sustain and to transmit the vibration to the moulding box. Vibration is by electric motor through belt drive or by VIBROMETER. Vibration is controlled by unbalanced weights provided on each side of spindle. The separated sand from the moulding box effectively, falls on the grid and flows to the bottom conveyor of sand plant. It stops the breakage of mould box and increases life. • Rigid construction to sustain & transmit the vibration to moulding box.• Vibrators are controlled by Rotary eccentric weights provided on both side of spindle• Stops the breakage of mould box & increase life.• Capacity - 500 kg. to 5000 kg.

CONTINUOUS VIBRATION STAKING MACHINES

Get Price Quote

FOREWORD: ' BUKE ' Continuous Vibration Staking Machine has been designed to soften the leather by staking operation. It provides a vigorous mechanical action on the leather and pulling the fibres apart so that they are permanently free from the stresses imparted during previous processes. It also helps in opening and spreading the leather thus enlarging its surface area remarkably. SALIENT FEATURES : 1. FULLY INDIGENOUS The entire machine is designed and developed indigenously at our works only. The complete frame structure is fabricated from graded steel and having high rigidity to withstand against vibrations during staking operation. 2. VERSATILE : The machine can be used for staking any type of leather in its proper condition having the required water content. The thickness of leather must not exceed 3.2 mm. Two pieces of leather upto 1.5 mm thick each, can be feed for staking simultaneously unless they are too stiff. 3. UNIFORM STAKING : After feeding the leather on table and bottom conveyor, it passes through the working area between top and bottom conveyor. The leather is pulled in all directions during staking operation in which the leather is staked in between upper and lower staking pins results in uniform staking effect. 4. ADJUSTABLE STAKING INTENSITY : The intensity of staking can be adjusted by changing the position of upper pin plate with the help of hand wheel provided on the top beams. This arrangement is suitable for staking leathers with different fibre strength, density, thickness and stiffness. 5. INFINITELY VARIABLE CONVEYOR SPEED : The Conveyor belts are driven by a 2 HP heavy duty infinitely variable mechanical speed variator. The speed of the conveyor belts can be varied infinitely from 6 meters / min to 18 meters / min. 6. SAFTY : The operator's safety is carefully ensured by means of following.:a) Guards provided on all driving mechanisms and rotating parts.b) All electric motors are provided with overload relays.c) The machine is fitted with a special device that prevents undesirable objects from entering into the machine. 7. REVERSING FACILITY : As an additional safety, the conveyor is also provided with a facility of reverse rotation if required by the operator in case of emergency.

Vibratory Press Machine

Get Price Quote

Vibratory Press Machine