dry fog dust suppression system

Get Price Quote

DRY FOG DUST SUPPRESSION SYSTEM Dry Fog Dust control Systems have been in operation worldwide. ECSS as Dry Fog Dust suppression system supplier in India make dual fluid (air and water) atomizing nozzles control virtually all breathable and fugitive dust THEORY AND APPLICATION The "Dry Fog" Dust Control System works on the principle of agglomeration. The Dust particles released from a Material Handling/Processing Plant which become air borne are made to pass through a blanket of extremely fine Fog. The dust particles and the Micronics size Fog droplets collide and adhere to each other, thus increasing their mass. After a series of such collisions, even the breathable and fugitive dust ranging from 1 to 800 microns mass agglomerates to become heavier enough to settle. The lower capital, operating and maintenance cost compared to De-dusting Bag House System made it popular in the industries. Easy installation in existing plants.In most cases, the system can be installed while the plant operates at full capacity. No major plant modifications are required for installation of the system.Water addition to the process is as low as 0.1% of the weight of the material being handled.No requirement of Chemical. Benefits Low capital cost Meets health and safety regulations No chemicals required Water addition to process is very minimum Low maintenance No expensive modifications required to existing plants Common Applications Primary and secondary crushing and screening Conveyor transfer points Loading facilities docks, silos and terminals Hoppers, feeders and bins Common Industries

Centrifugal Blower

15,000 Per Piece

Best Deals from Air Pollution Control Equipment

Discharge Electrode

Get Price Quote

Discharge Electrodes emit charging current and provide voltage that generates an electrical field between the discharge electrodes and the collecting plates. The electrical field forces dust particles in the gas stream to migrate toward the collecting plates. The particles then precipitate onto the collecting plates.Auro Impex & Chemicals ( P ) Limited offers under one roof various internals for all make Electrostatic Precipitators. We manufacture Discharge Electrodes of different shapes.

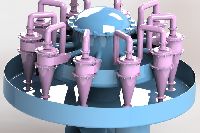

Hydrocyclone Cluster

Get Price Quote

In applications with higher flow rates multiple Cyclones can be accommodated within a single structure, hence reducing the floor space requirement greatly. All the structures are of reinforced steel, lined with superior wear resistant rubberceramics.The basic difference between Mushroom and Cluster is that the later can incorporate even more cyclones within a single system.

Collecting Electrodes

Get Price Quote

Collecting Electrodes are the collection surface made of sheet metal on which the particulate mater is collected after being negatively charged within the gas passage of the ESP. Designs of the plates vary from manufacturer to manufacturer. These plates are secured to the ESP shell at ground potential and serve as the positive anode of the gas passage. General details of the Collecting Plates are given below: - Raw Material: Normally the Collecting Plates are made of Carbon Steel. However, for some applications where carbon steel made plates are corroded regularly, these are manufactured with stainless steel or an alloy steel. Sheet Thickness: The thickness of the collecting plates range from 0.5 to 2.0mm. Spacing: The spacing between the plates vary for different designs of ESP. For example, ESPs with wire type of emitting electrodes, plates are spaced from 150 to 300mm apart. High-efficiency ESPs (using wires) has spacing of 200 to 230 mm. ESPs usingrigid-frame or plate type discharge electrodes have a spacing of 300 to 400 mm betwee the plates. Height: Collecting Plates are normally 6 to 14M high.

Collecting Electrode

Get Price Quote

Collecting Electrodes are the collection surface made of sheet metal on which the particulate mater is collected after being negatively charged within the gas passage of the ESP. Designs of the plates vary from manufacturer to manufacturer. These plates are secured to the ESP shell at ground potential and serve as the positive anode of the gas passage. Collecting Electrodes manufactured by Helios undergo a stringent quality control system which ensures straightness throughout the length of the plates. The finished plates are packed in steel crates for a damage free transit and handling.

Insertable Bag Filter

Get Price Quote

Insertable Bag Filter

portable dust collectors

Get Price Quote

portable dust collectors, pug mills, Ribbon Blenders

esp spares

Get Price Quote

esp spares, Air Compressor Spares, Pneumatic Tools

Collecting Electrodes

Get Price Quote

Collecting Electrodes are the collection surface made of sheet metal on which the particulate mater is collected after being negatively charged within the gas passage of the ESP. Designs of the plates vary from manufacturer to manufacturer.

Filter Bag

Get Price Quote

Filter Bag, Air Washers, Cyclone Separator, Ceiling Fan

Fabric Filter Bags

Get Price Quote

Fabric Filter Bags, waste treatment equipment

Hydrocyclones

Get Price Quote

Hydrocyclones, Mill lining, conveyor belt cleaners, trommel

Tega De-Sliming/De-Watering/De-Griting Hydrocyclones

Get Price Quote

Tega De-Sliming / De-Watering / De-Griting Hydrocyclones