Autoclaved Aerated Concrete Block Plant

12,500,000 - 25,000,000 Per Piece

1 Piece (MOQ)

Aac Plant

Get Price Quote

1 Piece (MOQ)

Best Deals from Autoclaved Aerated Concrete Plant

Aac Plant

Get Price Quote

1 Set(s) (MOQ)

brickvision equipment manufacture and supply best quality aac block plants on very convenient costs. Using the latest technology and hi-tech machinery we provide the best efficiency and time saving systems in our plants. The system is totally electronic based so as to make it cost saving, time saving and efficient as well. model : be-aac-hc-120discreption : this plant is fully automatic machinery : pree mixer, slurry pump, screw conveyor, batching system, micro feeder, plc based control panel, mixer, shifert, track , trolley, cutting machine, boiler, autoclave mad manny more machineryes loaded with full technology. for more details plz meet personaly with your details

Batching System AAC Plant

Get Price Quote

Aac Plants

Get Price Quote

Autoclaved aerated concrete (AAC), also known as autoclaved cellular concrete (ACC) or autoclaved lightweight concrete (ALC), was invented in the mid-1920s by the Swedish architect and inventor Johan Axel Eriksson It is a lightweight, precast building material that simultaneously provides structure, insulation, fire resistance, Construction Economy and Speed; AAC products include blocks, wall panels, floor and roof panels, and lintelsIt has been refined into a highly thermally insulating concrete-based material used for both internal and external construction. Besides AAC's insulating capability, one of its advantages in construction is its quick and easy installation, the material can be routed, sanded, and cut to size on site using standard carbon steel band saws, hand saws, and drills. Even though regular cement mortar can be used, 98% of the buildings erected with AAC materials use thin bed mortar, which comes to deployment in a thickness of 3 mm. This varies according to national building codes and creates solid and compact building members. AAC material can be coated with a stucco compound or cement plaster OR POP. Materials. Siding materials such as brick or vinyl siding can also be used to cover the outside of AAC materials • AAC has been produced for more than 70 years, and it offers advantages over other cementations construction materials, one of the most important being i ts lower environmental impact. • AAC’s improved thermal efficiency reduces the heating and cooling load in Buildings• AAC’s workability allows accurate cutting, which minimizes the generation of solid waste during use.• AAC’s resource efficiency gives it lower environmental impact in all phases of its life cycle, from processing of raw materials to the disposal of AAC waste.• AAC’s light weight also saves cost & energy in transportation.• AAC’s light weight saves labors. • Reduces the structural weight achieving great economy in RCC work • Low Construction Cost, with high speed output.Main ingredients include fly ash, water, quicklime, cement, aluminum powder and gypsum. The block hardness is being achieved by cement strength, and instant curing mechanism by autoclaving. Gypsum acts as a long term strength gainer. The chemical reaction due to the aluminum paste provides AAC its distinct porous structure, lightness, and insulation properties, completely different compared to other lightweight concrete materials. The finished product is a 2.5 times lighter Block compared to conventional Bricks, while providing the similar strengths. The specific gravity stays around 0.6 to 0.65. This is one single most USP of the AAC blocks, because by using these blocks in structural buildings, the builder saves around 30 to 35 % of structural steel, and concrete, as these blocks reduce the dead load on the building significantly.Assumption The major raw material Fly-Ash, an indispensable by-product of Thermal Power Plants, is an environmental threat across the globe. Power plants are facing an ever increasing challenge disposal of this polluting agent. This unit is proposed to manufacture AAC Bricks & Blocks by consuming the Fly-Ash as one of the prime raw material. Secondly, it also helps environment by saving the invaluable top soil by not using them in brick making like conventional brick making. Thirdly, they need no burning, thus further enhancing their Eco-Friendly Brand. The steam curing requires far less fuel, compared to the backing for each cubic meter of Bricks. This is the reason these bricks are also referred as Eco Bricks or popularly Green Bricks, Carbon Credit estimates are for reference purpose. The Project owner must handle his part of CDM project to get Carbon credits, through independent consultants. Carbon credit can be transacted on registration. The PCN preparation & presentation, the PDD preparation & presentation, host country approval and the UNFCCC Registration might take somewhat 6 months to 2 years year. So it may be wise to start early. Sale price at site is estimated a conservative Rs 3200/- per cubic meter. AAC Blocks of all sizes will be manufactured according to the market requirement, though mainly stipulated sizes as per the BIS standards. Production is estimated at 80% capacity, 300 working days is considered in a year during the first year.

Aac Plant

Get Price Quote

We are a leading manufacturer and supplier of aac block plant we have been associated to block manufacturing technology since 1990 , from concrete block to flyash bricks , clc and aac , we have seen the change in the market, the product and all the advantages and disadvantages. In aac we have setup multiple turnkey projects, making our team has capable to execute aac block plant projects with ease. Since we have been innovating products for construction industry, our latest vision is to make this technology affordable to the masses. We are also designing smaller size plants which will help to reduce capital investment.

autoclave aac plant

Get Price Quote

aac plant (designed & manufacturing by laxmi en-fab pvt. ltd.) the aac plant is designed to manufacture aerated concrete blocks used as building material. the blocks are manufactured using high quality cement, lime, aluminum powder and other aerating compounds, which provide great fire resistivity and compressive strength. the plant is able to make extreme light weight and large variety of sizes blocks and has excellent thermal insulation nature. our aac plant has the high rate of production capacity in a year. key features: precision designed and constructed heavy saddles for expanses excellent resistant to earthquake forces why aac block? it is advised that aac blocks should be used in high-rise buildings. advanced technology has been used in manufacturing of the blocks, known as autoclaved concrete. one of its feature is, it is the only durable thermal and fire rated material and so it works better than concrete and bricks. aac block are used as much as like concrete blocks but aac blocks are used mostly for wall floor and roof decks of buildings. all blocks are properly placed with thin bed mortar. aac bindermortar is prepared to be used as wet premix adhesive for blocks. aac blocks have a more accurate dimension and better comprehensive strength as compared to concrete block or clay brick building. it has better strength because of thin bed mortar which provides better strength to aac blocks. it is used in many load bearing application whether heavy or small job.

Industrial Aac Plant

Get Price Quote

Industrial Aac Plant that we manufacture, export and supply is widely in demand across the globe. Our team of professional engineers design and develop our Industrial Aac Plant using high-grade parts & components as well as the latest technology. Our plant is accredited for robust construction and reasonable price. In addition, we undertake on-site assembly of our Industrial Aac Plants.

Autoclaved Aerated Concrete Plant

30,000,000 Per Set

Sand Aac Plant

7,500,000 Per Set

1 Set(s) (MOQ)

AAC Consultation

1,000,000 - 3,500,000 Per set

undefined undefined (MOQ)

Brickwell also offers consulting services for AAC Block Manufacturing Plant, Set-up AAC Brick Manufacturing Plant : Setting up of Plant for manufacture of AAC Bricks from Planning, identifying area of working to identifying land, deciding equipments, negotiating vendors, Turnkey basis right from the stage of site survey, layout plan, Plant/machinery Decision, Looking into civil construction of site, commissioning, Trial Production and training of engineers & workers to run the plant on commercial basis.

Aac Plant

50,000,000 - 80,000,000 Per Piece

1 Piece (MOQ)

Autoclaved Aerated Concrete Plant

Get Price Quote

We are offering european non autoclaved aerated concrete plant (naac). This set of equipment is designed to produce the aerated concrete blocks. The mixer for aerated concrete is placed fixedly, the moulds transfer from pouring point to cutting point. Loading and dosing of components are carried out automatically - the materials through belt and screw conveyors are fed to intermediate hoppers suspended on the tensiometers. Dosing control terminal in case of reaching required weight turns off the conveyors. Components are poured into the mixer manually by opening of the bolt. Cutting of an array is carried out with the automatic cutting installation. Movement of the moulds on the rail track is organized through automatic push devices.

Autoclaved Aerated Concrete Plant

Get Price Quote

European plant available in India (Non-autoclaved technology) It is also known as light weight brick machinery & light weight bricks making machine. he aerated concrete blocks. The mixer for aerated concrete is placed fixedly, the moulds transfer from pouring point to cutting point. Loading and dosing of components are carried out automatically - the materials through belt and screw conveyors are fed to intermediate hoppers suspended on the tensiometers. Dosing control terminal in case of reaching required weight turns off the conveyors. Components are poured into the mixer manually by opening of the bolt. Cutting of an array is carried out with the automatic cutting installation. Movement of the moulds on the rail track is organized through automatic push devices.

Aac Plant

Get Price Quote

1 Piece(s) (MOQ)

We offer aac plant. We are pleased to introduce ourselves as machinery manufacturers and technology providers from new delhi, india for aac plants and other building material projects, fly ashsand lime bricks etc. Our conceptprinciple of business is to provide technology and machinery equal or better than european at economical prices. neither we represent any chinese company nor we use any chinese parts for manufacturing of machinery. we take up aac and other building material projects from concept to commissioning which includes detailed engineering (civil, mechanical, electrical, automation and utilities), machinery selection and manufacturing, erection of total machinery and commissioning we have studied all types of aac plants supplied by chineseeuropean manufacturers and have incorporated several improvements and innovations based on our experience of operating cementfly ash solid bricksblockshollow blockspavers plants with modern automation systems. We are using superior quality components in all the key machinery manufacturing apart from maintaining quality manufacturing techniquesspecifications apart from maintaining highest standards in design engineering of all the machinery from a bolt to critical machines. We request you to visit us to understand our capabilities and quality of machinery being manufactured by us. On your inspection, we are sure you will agree that our concepts and the quality standards being maintained by us are comparable to european and not with chinese. Input costs are approximately as under: density of blocks: 600 kgm3 fly ash: 70-75% = 420-450 kgm3 lime: 7-8% = 48-60 kgm3 (to be obtained from rajasthan) cement: 15-18% = 90-108 kgm3 gypsum 1-2% = 6-12 kgm3 aluminum powder = 0.4-0.5 kgm3 aac(cost about rs. 200 per kg) power 12 kwhm3 boiler fuel: 40 kg coalm3 or equivalent alternate fuel like firewood or rice husk

Autoclaved Aerated Concrete Plant

Get Price Quote

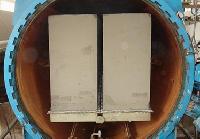

AAC Block making plant is a highly thermally insulating concrete-based material used for both internal and external construction. Besides AAC's insulating capability, one of its advantages in construction is its quick and easy installation, because the material can be routed. AAC is well suited for urban areas with high rise buildings and those with high temperature variations. Due to its lower density, high rise buildings constructed using AAC require less steel and concrete. Autoclaved aerated concrete is cured in an autoclave - a large pressure vessel. In aircrete production the autoclave is normally a steel tube some 1.6 meter in diameter and 31 meters long. Steam is fed into the autoclave at high pressure, typically reaching a pressure of 800 kPa and a temperature of 180 °C. The autoclaved aerated concrete production process differs slightly between individual production plants but the principles are similar. We will assume a mix that contains cement, lime and sand; these are mixed to form a slurry. Also present in the slurry is fine aluminum powder - this is added to produce the cellular structure. The density of the final block can be varied by changing the amount of aluminum powder in the mix. We are offering our clients wide range of AAC block, Manufactured as per the international standards. The products are fabricated using the high grade raw materials. Our products are highly demanded in the industry for their superior quality.

Autoclaved Aerated Concrete Plant

Get Price Quote

Autoclaved aerated concrete (AAC), also known as autoclaved cellular concrete (ACC) or autoclaved lightweight concrete (ALC), was invented in the mid-1920s by the Swedish architect and inventor Johan Axel Eriksson It is a lightweight, precast building material that simultaneously provides structure, insulation, fire resistance, Construction Economy and Speed; AAC products include blocks, wall panels, floor and roof panels, and lintels, AAC has been produced for more than 70 years, and it offers advantages over other cementations construction materials, one of the most important being i ts lower environmental impact.

Aac Plant

900,000 Per Piece

Aac Plant

Get Price Quote

Autoclaved Aerated Concrete (AAC) is a fully integrated building system of panels and blocks that are used for residential, commercial and industrial buildings. AAC, a light-weight green building material, is fire resistant and has good thermal insulation, solid structure and is easy to work with. AAC is manufactured by about 200 plants in 35 countries and is used extensively in residential, commercial and industrial buildings.Biltech Building Elements Limited, an Avantha Group Company is engaged in mechanised manufacture of this revolutionary building material in India. Currently BBEL has over 40% of the market share with a capacity of 13, 40, 000 cu.m. per annum. Factory manufactured BILTECH products, make constructive use of pollutant Fly Ash, copiously spewed by Thermal Power Stations. With its manufacturing facilities in north, east and western India, and some more plants coming up in other parts of the country to facilitate pan-India presence and reach, BILTECH commands the status of the largest Fly Ash based AAC manufacturer in India.

Autoclaved Aerated Concrete Block Plant

Get Price Quote

1 Set(s) (MOQ)

We are offering autoclaved aerated concrete plant we are specialized supplier of complete set of autoclaved aerated concrete plant with 50000, 100000, 150000, 200000, 250000, 300000, 350000m3 capacity annually (from 200 m3 to 1000 m3 per day), including plant design, equipments installation, technical instruction, personal training, etc., and also we design and manufacture as per clients' requirement. Autoclave aerated concrete production line included: raw material: cement, lime, sand, gypsum, aluminum powder, water. Equipment list: the equipment will be divided into two parts: specialized equipment and universal equipment. Specialized equipment includes: 1.cutting equipment: tilting crane, cutter. 2. Proportioning equipment: electronic measuring scale, slurry beating machine, slurry storage tank, slurry mixer. 3. Pouring and autoclave equipment: aluminum powder mixer. Pouring mixer, mould, side plate, autoclave truck, carrier car. 4. Conveying equipment: semi-product crane, end product crane. Universal equipment includes: 1. pressure vessel equipment: boiler, autoclave. 2. Crushing equipment: ball miller, crusher. 3. Transportation equipment: crane, lifting machine, feeder, belt conveyor, slurry pump, screw conveyor. 4. Enviornment protect equipment: dust remover

Autoclaved Aerated Concrete Plant

Get Price Quote

AAC blocks are one third lighter than conventional clay bricks, thereby reducing the dead weight of the structure drastically,Light weight structure decreases construction cost due to reducing steel, Cement and Excavation.Our Case Study Shows Following Results Reduction in steel = 15 % Reduction in cement = 10%.Due to reduction in dead weight, Reduction in consumption of steel and cement and lesser excavation for foundations, construction time is reduced which in turn results in savings in labor cost and overheads.

Aac Plant

Get Price Quote

Backed by a rich industrial experience, we are engaged in offering a commendable array of AAC Plant. Features: Reliable Longevity Industry proven designs

Aac Plant and Machinery

Get Price Quote

We provide complete solutions for aac plants from consulting to design, manufacture, commissioning and service. We specialize in small to mid-size plants that can be later expanded for large scale production making it easier for our customers to enter the aac space with adequate capital and create a name for themselves before launching a full scale outfit. Combine this with our service quality for excellent results throughout and we present a profitable proposition. For more information, please visit our website.

Autoclaved Aerated Concrete Plant

Get Price Quote

Mortuary Chamber, Water Bath Shaker, Low Temperature Bath, Orbital Shaker

Autoclaved Aerated Concrete Block Plant

Get Price Quote

Aac block adhesive plant

Autoclaved Aerated Concrete Plant

Get Price Quote

Orilite block at best price

Aac Plant

Get Price Quote

Aac Plant, Tile Ceramic, ceramic raw material

Aac Plant

Get Price Quote

Aac Plant, Steam Boiler, Light Weight Concrete Block Machine

autoclaved aerated concrete blocks manufacturing plant

Get Price Quote

autoclaved aerated concrete blocks manufacturing plant

Autoclaved Aerated Concrete Plant

Get Price Quote

CLC Autoclaved Concrete Plant