Zero Oil Filter

Special Features :- It is specially designed to remove all three states of oil i.e. liquid oil, oil/water emulsion and oil vapour with high degree of accuracy. Construction :- The outer casing is made of fabrication or casting to withstand high pressure. The elements are generally made of sintered bronze etc. as per application. Application :- It is recommended where absolute oil free air and gas (99.999%) is required..

...more

Y Strainer

Connection Size :- 15 NB to 450 NB (Screwed & Flanged End).. Pressure & Temperature :- 8.92 Bar @ 179 Deg. C (Hot) to 100 Bar @ 37.8 Deg.C (Cold). Construction :- The outer casing is made of fabrication or casting to withstand high pressure the elements are generally made of perforated sheet & wire mesh of SS-304, SS-316 etc. as per application. Application :- These filters are generally used for in-line liquid filtration system.

...more

synthetic filter

Media & Construction :- 3 or 5 ply HDPE crimped with 1 layer of PVC net by which the media becomes noncorrosive. It is encased in metallic panel type frame duly guarded by grill (on option). Application : It is applied for pre filtration in air conditioning & ventilation system etc.

...more

semi absolute filter

Media & Construction :- Made of fine water resistance, pleated glass fibre media which is spaced by aluminium spacer. It is housed in a single or double flanged G.I. Casing. Application : It is applied to fine filters for air separation plant, centrifugal compressors, Gas Turbine units etc

...more

Self Cleaning Filter

Working Principle :- It operates on edge filtration principle and no replacement of element is required. Special Features :- It is of 2 types, Manual and Automatic. In manual type a handle is fitted on the top which have to be manually rotated to clean the element., in automatic type rotating is done by motor itself to clean the element. Construction :- The outer casing is made of fabrication or casting to withstand high pressure. The elements are made of metal plates hence no replacement of element is required. Application :- It is suitable for any type of viscous liquid (Lube Oi, Hydraulic Oil, Other petroleum oil, coolant fluid, water / oil emulsion) etc.

...more

Rollomatic Filters

Media & Construction :- It is an automatic roll type filter in which the media is automatically rolled after it had accumulated its dust load. The media is generally made of glass fibre & synthetic fibre. Application : It is applied in air conditioning & ventilation system, painting cabines, cooker hoods ( Fume absorbers).

...more

Rod Panel Air Filter

Application : It is applied for fine filtration in air conditioning & ventilation system etc.

...more

Rain protection Suction Air Filter

Media & Construction :- Cellulose paper resin bonded, Hdpe wiremesh 3 to 5 layers, Coir pad along with zigzag cotton & metallic media. This filter are two type:- 1. Circular , 2. Box Application : Suction side of Compressor, Generator & industrial Machinery.

...more

PVC Sheet Mio Filters

Media & Construction :- Suitable grade of PVC sheets (Several Layers) are specially perforated, crimed and arranged into a metallic casing. The casing is protected by metallic weld mesh / rod on both sides. Application : It is applied for pre filtration in heavy duty uses, side wall ventilation for car body and diesel loco for corrosive environmental uses.

...more

Pulse Paper Filter

Media & Construction :- Organic endure type paper is pleated, separated and encased in a specially designed metallic casing. The pleats are duly spaced as well as reinforced by lines of special adhesive. Cleaning is done by air pulsing. Application : It is applied in augmented self-cleaning air filtration system, Gas Turbine.

...more

Pulse Jet Dust Collector

Dust Collecting hopper with baffle plate or drop out section Filter chamber Clean gas exhaust chamber Cleaning device The dust laden air enters through inlet of the hopper where baffle plate or drop out section act as a precollector by helping the coarse dust to fall down into the hopper & also it helps air to reduce its velocity with equivalent distribution throughout the filter chamber. Cadillac provides an inspection Door on the hopper. In special cases, where dust are fine top entry can be offered. Filter chamber are equipped with bag filter,cage,venture, Cadillac experience engineers give special attention on selection of Bag Filter fabric, Keeping in mind the type & nature of dust,dust load,temp. of gas,emission level, atmospheric condition etc. For normal application polyester needle felt is being used (temp.100 to 150 degree centigrade) & for high temp. aramide needle felt is used (temp. 180-200 deg.c.). Cadillac can provide cartridge type bag filter where space is constrained. Clean gas exhaust chamber contains bag holding plate or cage plate, blast pipe, accessible door, outlet of gas. We give special attention on cutting of bag holding plate because its provide proper sealing & perfect alignment of the case with the bag. The blast pipes are connected by union joint to maintain automatic alignment with the filter bag. Venturis are set properly with the cage or cage plate to provide support for dedusting of filter bags. This clean chamber is completely accessible by its door. Also railing & platform is provided for support. Cleaning devices, consist of manifold tank which contain compressed air at a pressure about 6-8 kg./sq.m is connected with a solenoid operated diaphragm valve, which are connected with the blast pipe. The compressed air should be oil & moisture free air. The sequential timer is used to control the several diaphragm valve with an extra features of D.P. mode. A.D.P. switch senses the different pressure between clean chamber & filter chamber & start the pulsing. In normal condition timer control the pulsing of diaphragm valve. When dust laden air flows through the filter bag, where the particulates larger than the fabric interstices are deposited on the bag surface to form a cake of dust which act as a efficient filter. When sequential timer starts the diaphragm valve it starts pulsing the filter bag & the bag stretches & excess adhering dust drop to the dust hopper which is removed from hopper by dust discharging device like ravs, chute, screw conveyors etc.

...more

Pocket Bag Filter

Media & Construction :- It is made of hyloft, HDPE, Synthetic Felt, sandwiched with nylon cloth / tissue, PES (2 to 12 Nos.). Pockets are made in a metallic frame to makes its fitment easy. Application : It is applied in air ventilation system e.g. sophisticated industrial assembly rooms, hospitals, airport, for dust collecting in cement plants, brick processing units etc

...more

Pass Box

Our world class range of Dynamic Pass Boxes are designed in conformation to the international standards and are used for transferring the material from and into the cleanroom, without contaminating the air of clean room. In the process, room door is not required to open. These can be easily be installed on the wall between the clean room and other room.

...more

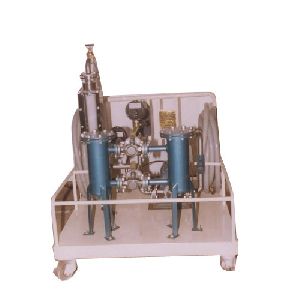

Oil Filtration Plant

Application:- These filters are generally used for Oil Filtration Plant system.

...more

Moisture Separator

Special Features :- It is specially designed to reduce moisture and oil content from 2000 PPM to 100 PPM at a very low pressure drop. Construction :- The outer casing is made of fabrication or casting to withstand high pressure. The elements are made of absorbent & coalescing media. Application :- It is most suitable for installing in compressed air line for removal of moisture, oil, scale, and other particles (95% down to 3 micron).

...more

Mini Pleat Hepa Filter

Media & Construction :- The basic media of these filters are either glass fibre paper or cellulose and synthetic fibre mix paper. The separator used are hot melt type and are suitable to work upto temp. of 100 C. The media is encased in aluminium, G.I. frame with no metallic spacers. Application : It is applied for multi stage filter system in ACVS, Micro electronic, medicine and compressors.

...more

Laminar Flow Bench

Hydraulic Filter

Special Features :- These filters safeguard the performance and service life of essential and expensive hydraulic components due to their high standard of quality. Application :- It is suitable for any type of viscous liquid (Lube Oil, Hydraulic Oil, Other Petroleum Oil, Coolant Fluid, Water / Oil Emulsion) at constant pressure drop. Filtration :- 3, 5, 10 and 20 micron nominal. Pressure Range :- 5 to 300 Bar. Construction :- The outer casing is made of fabrication or casting to withstand high pressure. The elements are generally made of hydraulic paper (cellulose based). Glass fibre paper with supporting wire mesh of SS-304, SS-316.

...more

Housing Pocket Bag Filter

Media & Construction :- It is made of hyloft, HDPE, Synthetic Felt, sandwiched with nylon cloth / tissue, PES (2 to 12 Nos.). Pockets are made in a metallic frame to makes its fitment easy. Application : It is applied in air ventilation system e.g. sophisticated industrial assembly rooms, hospitals, airport, for dust collecting in cement plants, brick processing units etc Additional Information: Item Code: CPFC

...more

HEPA Filter

Media & Construction :- Filter media fabricated from water repellent 100% micro glass fibre paper pleated over corrugated aluminium/paper board separator, encased in an GI /Al frame.Neoprene sponge rubber sealing provided for leakproof sealing Application : Cleanroomof class 1000 & below,Operation Theater,Control room.

...more

HEAT LESS AIR DRYER

Construction Features:- Heatless Compressed Air Dryer system (air drier) and gas dryer system for moisture removal in air & gases, These Compressed gas and air dryers (air driers) find use in majority of Industrial compressed air system and pneumatic applications. These air and gas dryer (air drier) are also offered for High Pressure gas and air drying system and applications. Following is a brief description of the working of these compressed air dryers and gas dryer systems. A Heatless compressed air dryer (drier) is the simplest form of desiccant type gas or air dryer (drier) for achieving a dew point of -40°C or better for compressed air systems and other gas and air dryer (drier) applications. Process:- Wet incoming Compressed air after passing through pre filter passes through the slide piston valve assembly and is directed towards adsorber chamber I where the compressed air passes upward through the desiccant (Activated Alumina / Molecular Sieves). Compressed Air drying takes place by adsorption. Dry Compressed air from adsorber chamber I then passes through the Check valve assembly and then through the after- filter to the application or work area. While Compressed air is being drying in chamber I the desiccant in chamber II where the desiccant has been wetted in the previous cycle is being simultaneously regenerated. The chamber II is depressurized to atmosphere through the purge valve in the downward direction. A portion of the dry compressed air passes through the needle valve / orifice plate through the desiccant and flushes out the desorbed moisture. When the regeneration is complete, the purge valve is closed and the tower is slowly repressurised to line pressure for a smooth changeover. A drying period of 5 minutes provides an efficient dew point of -40°C or better (at atmospheric pressure). In regeneration process approximately 30 seconds are required for repressurization.

...more

HDPE PLY Filter

Media & Construction : Suitable HDPE wire mesh (3/5 layers) is pleated in deep folds to provide maximum area of filtration. It is encased in a panel type metallic frame. Pleats are uniformly separated by metallic spacer. Application : It is applied for pre filtration in air conditioning & ventilation system etc.

...more

Gas Filter

Special Features :- It is specially designed to eliminate liquid droplets from industrial gas. It can also remove solid particle down to 1 micron. Construction :- The outer casing is made of fabrication or casting to withstand high pressure. The elements are generally made of sintered bronze, sintered plastic, synthetic and woolen felts, glass fibre etc. Application :- It is suitable for any type of gas line e.g. oxygen, hydrogen flue gas etc.

...more

Garment Cabinet

Annual Maintenance Contract

CLEAN ROOM VALIDATION

Be first to Rate

Rate ThisOpening Hours