SCREW FEEDER

Get Price Quote

weigh feeders

Get Price Quote

SITRANS weighfeeders from Siemens can improve the accuracy of processing, blend consistencies, accountability, and record keeping. All weighfeeders come standard with a belt weigh bridge and speed sensor. An integrator is required to complete the system. The weigh feeder is used to deliver an accurate mass flow rate of material. In the majority of applications, material is profiled by an adjustable mechanical shear gate, which fixes the correct material bed depth for a given particle size. SITRANS WW100: High-accuracy, low-capacity for minor ingredient additives SITRANS WW200: Low- to medium-capacity for minor ingredient additives SITRANS WW300: Medium- to high-capacity for macro ingredient additives SITRANS WW350: Medium- to high-capacity for macro ingredient additives The feed rate is then maintained and adjusted by varying the speed of the belt. However, in some cases the belt speed is constant with rate control (if any) done by a pre-feeding device.

Best Deals from Conveyor Feeder

Weigh Belt Feeder

300,000 Per Unit

Weigh Feeder

Get Price Quote

AMSTEL offers Weigh Feeders to feed bulk solids continuously to the process In a Weigh Feeder, product is fed as a continuous band onto a conveyor belt, through an inlet slide gate or automatic pre-feeder. Load cells under the belt continuously measures the weight of the product over a defined length of belt. The Weigh Feeders are suitable for installation in industrialized environment with light & heavy duty conditions respectively. They are specifically designed to provide dependable service with minimum maintenance and care. Heavy duty, Long life components are selected to assure a stable and distortion free compact assembly capable of withstanding tough industrial conditions.High quality measurement and control electronics allow both convenient operation and extensive monitoring, assuring high accuracies of feed. Weigh Feeders are able to control in continuous mode, the flow of the discharged material maintaining the instantaneous flow rate constant with respect to the set rate. The weight is measured directly at the weighing zone sensed by a centrally placed weighing idler which is placed on two numbers of high precision load cells. A digital tachometer detector generates the signal in proportion to the speed of the belt. The AMSTEL DATAWEIGH series controller continuously compares the actual weight with the set point weight, and automatically adjusts the motor speed to either increase or decrease belt speed, in order to maintain a constant feed rate. Any variation in the density of the material is reflected as a change in belt loading, which is compensated for by adjusting the belt speed

Gravimetric Weigh Feeder (MGWF)

Get Price Quote

Presently, Rotorvane Feeding is being done manually, which does not ensure even 70% accuracy in the uniformity of feed rate continuously for the whole operational period. Even combined with the highest intensity of applied supervisory control it cannot ensure the uniformity. TO OVERCOME this problem, Stesalit has designed and developed the Gravimetric Weigh Feeder (MGWF - 03) for uniform feed of withered leaves into Rotorvane. System Overview Uniform rate of feed to Rotorvane is very much important to achieve the proper preconditioning of leaf and better cut in CTC machine. Our Gravimetric Weigh Feeder (MGWF-03) is an uniquely designed equipment, to achieve this objective of uniform feed rate to Rotorvane within an accuracy limits of around 95% of the uniformity of feed rate. The irregular or uneven feeding of leaf by the workers into MGWF does not affect the uniformity of feed rate from MGWF to the Rotorvane. This results in better and uniform quality of tea made and also saving in energy and reduction in the maintenance costs of Rotorvane. The uniform feeding in Rotorvane, through MGWF, is achieved by automatically changing the conveyor�s belt speed according to the leaves fed into MGWF-03. (If leaves are fed less than the speed of conveyor will increase and if leaves are fed more, then speed of conveyor will decrease, based on preset feed rate ensuring uniform feed rate to Rotorvane. Stesalit has installed more than 500 units of MGWF-03, in many leading tea factories in India and abroad, which are working satisfactory, some of them for over 8-9 years.

volumetric feeder

Get Price Quote

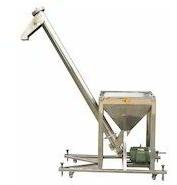

SCREW FEEDER

70,000 Per Piece

weigh feeders

Get Price Quote

sweipl, in collaboration with saet, italy offers weigh feeders to feed bulk solids continuously to the process . The weigh feeders –dprc & dpn are suitable for installation directly under the silos in industrialized environment with light & heavy duty conditions respectively. The former has been designed to handle small size granulated material whereas the latter can cater to a complete range of material size. high quality measurement and control electronics allow both convenient operation and extensive monitoring, assuring high accuracies of feed. Belt weigh feeders are able to control in continuous mode, the flow of the discharged material maintaining the instantaneous flow rate constant with respect to the set rate. The weight is measured directly at the weighing zone sensed by a centrally placed weighing idler which is placed on two numbers of high precision, international class load cells having high resolution strain gauges of minimum displacement (0.1mm). A digital tachometer detector generates the signal in proportion to the speed of the belt.the device is supplied complete with a command and control cubicle, equipped with our electronic weighing system ws200/d series. the belt load and speed signals are routed through the microprocessor based weighing and feeding controller, where they are processed and an actual feed rate is continuously compared with the set rate (set point) to assure that the belt speed is controlled such that the feed rate is maintained at a constant level throughout. Precision attained is superior to ±0.5% of the set flow rate. The weighing systems compensate the apparent density variation within a range of ±30%. The supporting structure of the weigh feeders may be so designed to be an integral part of the fairing that encloses the machines. As this guarantees completely dust tight protection so pressure proofing, if needed, is possible. the closed ring vulcanized rubber belt can be easily replaced without requiring the disassembly of the machine components. Automatic belt tracking prevents disruption to process by belt running askew. Belt drift, if any, is monitored with the aid of opposite limit switches. gravity take ups assure constant but tension preventing belt slippage & overworking.to improve performance a speed sensor is installed at tail pulley to detect belt slippage if any. Two prevent belt contamination and tare changes an adjustable scrapper outside the belt, while a plough defector inside the belt has been used as a suitable design for belt cleaning system. The plough deflector prevents belt destruction due to foreign objects jammed between belt and pulley. Available on request are sundry solutions with the use of scrapes, collecting screw feeders, hoe scrapers. options:1. Fairing2. Special scrapper3. Feeding hopper4. Conveyor belt with containment edges5. Second weighing bridge (for dpn only)6. Prefeeders – feed hopper, star feeder, shaker etc (for dpn only) for each bulk material the right feed hopper /prefeederfeed hopper for free-flowing materialvibrating hopper for sluggish materialsstarfeeder for flushing materialsfeed gate for fluidized materials

SCREW FEEDER

Get Price Quote

We are offering Screw Feeder. This product is capable of delivering dense slurries and dry granular products with great accuracy at a range of operational speeds. Our company has earned accolades in offering Screw Feeder to the clients. Screw Feeder is a device used in various industries to accurately meter or feed amorphous or loose grained material from one part of a process to another. This product is very similar to screw conveyors in basic structure, both of which are based on the principles for their operation. We are looking inquiry from Ranchi " Bihar, Kolkata, West Bengal, Guhawati, Patna, Bhubaneswar, Tripura, Sikkim, Nagaland, Mizoram, Meghalaya, Manipur, Arunachal Pradesh, Assam, Orissa. Features: Light weight Best grade material Quality approved

belt feeder

Get Price Quote

Belt Feeders are used in Manufacturing and Process Industry to measure or feed Bulk Material at desired Gravimetric Rates on a continuous basis. The Equipment is provided with a set of Precision Load Cell Mounted Idlers which measure the weight of the material on the Belt, dynamically, over a weighing zone. The signal is then transmitted through one Junction Box to the Microprocessor based Weigh Feeder Controller. The Controller provides output signal of the actual feed rate and also controls the speed of the Belt to maintain the target value. One Rotary Speed Encoder fitted on the Drive Drum gives the actual speed value as a feed back to the Weigh Feeder Controller. The speed of the Belt is continuously changed by the output signals of the controller to one Variable Voltage Variable Frequency Inverter Drive which maintains the speed of the Belt for maintaining the Drive output. Optional data print out is available from the Weigh Feeder Controller to obtain the cumulative weight of the product conveyed over the given period of time. The Controller has provisions of registering in memory for 21 (3 x 7) shifts, the total production with Field adjustable shifts timing and clock.

Weigh Feeder

Get Price Quote

We are main supplier of this product.

Weigh Feeder

Get Price Quote

Weigh Feeder, Metal Detector, unmanned weigh bridge, Weigh Bridge

Conveyor Feeders

Get Price Quote

Travelling Trippers, bulk handling cranes, Ball Grinding Mill

Coal Feeder

Get Price Quote

Coal Feeder, boiler parts, coal mill spares, dm coal, DM Plant, Coal Mill

Weigh Belt Feeders

Get Price Quote

Weigh Belt Feeders, Continuous Chemical Withering (Tray Type)

volumetric feeders

Get Price Quote

volumetric feeders, Brabender Loss In Weight Feeders, Loss-In-Weight Feeder

belt feeder

Get Price Quote

belt feeder, Universal CL / SL, Gutty Belt

concrete weigh batch feeder

Get Price Quote

concrete weigh batch feeder, Chapati Making Machine, Concrete Mixer