Mild Steel Hammer Crusher

350,000 Per Piece

5 Piece (MOQ)

PET Bottle Crusher Machine

Get Price Quote

Best Deals from Crushing Machine

Jaw Crusher Machine

88,960 - 94,860 Per Nos

1 Piece (MOQ)

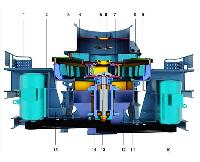

Swing Hammer Crusher

Get Price Quote

Swing Hammer Crushers are used daily in the mineral, ceramic and metallurgical industry among others to crush and pulverize material such as coal, plaster, salt, fire clay and other materials. Our products boast of a high crushing ratio and proven operational excellence. We also ensure that our equipment is easy to maintain and that it follows international standards of safety. The device has a controlled feeding arrangement which can be altered according to the client requirement. Details : We are a profound industry engaged in manufacturing and supplying a wide range of Swing Hammer Crusher. The offered range is manufactured using high-grade material that is sourced from reliable vendors of the market. Our experienced professionals stringently inspect these crushers on certain well-defined parameters of quality in order to rule out every possibility of defect. This range is widely used for crushing & pulverizing various material such as coal, salt, plaster, alum, brick, fire clay, clay, george & other minerals. Comprise of: Controlled feeding arrangement Hammers that are fitted with spindle and rotor Breaker plate Screen bars having suitable gap opening Features: High crushing ratio Operational excellence Easy maintenance Durable standards Anti-corrosive Application areas: Ceramic industry Mineral handling Food and beverages Chemical industry Petrochemical sector Metallurgical areas

ice crusher machine

6,250 Per Piece

1 Piece (MOQ)

Plastic Crushing Machine

185,000 Per Piece

Laboratory Jaw Crusher

Get Price Quote

We Bring Forth Superior Quality Laboratory Jaw Crusher. Our Laboratory Jaw Crusher Ptc/ Labquip are Useful to Crush Chemical L Lumps, Mineral, Aggregate Etc. the Laboratory Jaw Crusher Has Heat Treated Steel Jaws. Opening of the Jaws is Adjustable from 25mm to 6mm. the Crusher is Made of Steel. the Jaws have Forward and Downward Strokes with Sufficient Rocking Action to Throw the Crushed Materials Down to the Jaws. a Hopper is Provided At the Top for Pouring Material the Output Depends Upon the Type of Materials to Becrushed and Varies from Material to Material.

Jaw Crusher

Get Price Quote

The new versions of jaw crusher launched are the latest development to complement FINLAYS' extensive range of mobile Crushing, Screening and Washing plants. Its compact size, ease of transport, and quick set-up times makes them ideal for contract crushing and demolition/recycling applications.

rock crushing machine

Get Price Quote

We are the main supplier of this product.

Primary Jaw Crusher Machine

Get Price Quote

Soil Crusher

Get Price Quote

Soil Crusher is used for subsoiling and breaking the clods formed after subsoiling. We hold expertise in manufacturing and supplying Soil Crusher with 5 anchors. It has a working width of 6 feet. Our Soil Crusher is appreciated for working at the required depth uniformly crushing the soil without upsetting its organic balance. Further, our Soil Crusher is made available at market leading prices.

Hpc Cone Crusher

Get Price Quote

Base on the latest technology and decades of years producing experience, SBNITH designed the HPC series cone crusher. It has excellent crushing efficiency and good hydraulic control system. Now the HPC series cone crusher has wide application in secondary crushing of many kinds of mining and rock, etc.

Mobile Crusher

Get Price Quote

Mobile crusher station is my company to meet market demand, independent research and development of full hydraulic drive tracked vehicle screening

Jaw Crusher-01

Get Price Quote

With the vast experience of more than a decade, we provide a comprehensive range of double toggle jaw crusher. Today, we are counted among the prominent jaw crusher manufacturers, based in India. Robust secondary jaw crusher is perfect for secondary crushing with brilliant compression strength. They are manufactured from the optimum quality raw materials using high technology machines to ensure their durability. This is widely known in the industry as size reduction equipment as it provides excellent results with easy maintenance and low power consumption. We have successfully installed various plants up to 200TPH in Jaw-Jaw combination as well as in Jaw-Cone combination in both formats i.e. stationary as well as mobile. After the huge success of them, we are engaged in manufacturing of following jaw crushers: Stationary Mobile 10TPH 10TPH 20-30TPH 20-30TPH 30-40TPH 30-40TPH 40-50TPH 40-50TPH 50-60TPH 50-60TPH 65-80 TPH 65-80TPH 100-120TPH 100-120TPH 120-150TPH 120-150TPH 150-200 TPH 150-200TPH

Jaw Crusher

Get Price Quote

We are leading supplier of huge range of jaw crusher

Ice Cube Crusher Machine

3,400 Per Piece

Jaw Crusher

Get Price Quote

OM series jaw crushers are robust equipment with high durability, designed with high quality raw materials. Combination of high reduction ratios at enhanced productivity - balanced high inertia Cast Steel flywheels; Cast parts are manufactured from ASTM A216 steel. Symmetrical chambers ensure interchangeability of wear parts. Side plates, Jaws, Liners are of high Mn content; Jaw plates are reversible end-on-end to minimise waste. Heavy-duty eccentric shaft and 4 identical bearings - results in superior durability and reliability. The split bearing housings guarantee a perfect fit to the machined housing, reducing loads to the bearings. It also facilitates the maintenance of the bearings without disassembly of the machine or any major dismantling in order to carry out servicing in site. IC Jaw crushers can be easily mounted on fixed installations and mobile units – wheeled or track. Modular structure and compact size ensure excellent mobility, wide ranging mounting options and short installation and set up time, whatever the duty. Aggregates, production of gravel, iron ores, other hard & abrasive ores - our Jaw crushers represent the best selection.

Hammer Crusher

Get Price Quote

Coal Crusher

Get Price Quote

Coal crusher is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. Here the breakage can take place in a much shorter scale compared to fragmentation process used in cone or jaw crushers. It can crush material with feeding size not more than 500mm and crushing strength not more than 350MPa. It can produce cubic products with very good grain shape without tension and crack .

sugar crushing machine

75,000 Per Piece

ELECTRIC CRUSHER

Get Price Quote

2030 Single Toggle Jaw Crusher

Get Price Quote

2030 Single Toggle Jaw Crusher, Smst Gear Box

Ore Crusher

Get Price Quote

Ore Crusher, Steel Balls, Crushing Machine, Grinding Machine

Vertical Shaft Impactor

Get Price Quote

Vertical Shaft Impactor, Jaw Crushers, Construction Machinery

industrial crusher

Get Price Quote

industrial crusher, Drill Machine, Electric Motor, Grinding Machine

vertical shaft crushers

Get Price Quote

vertical shaft crushers, Cone Crushers, industrial cone crushers

Industrial Crushers

Get Price Quote

Industrial Crushers, wobbler

Stone Crusher

Get Price Quote

Stone Crusher, Fire Hydrant, Fire Entry Suit, Fire Extinguisher

Jaw Crusher

Get Price Quote

Laboratory Ovens, Water Bath, Glassware, Thermocouple, weighing balances