RO DM Water Plant

Get Price Quote

1 Unit (MOQ)

demineralization water treatment plant

Get Price Quote

Best Deals from Demineralisation Plants

DM Plant and Mix Bed Plant

Get Price Quote

Ozone Generation

Get Price Quote

With wide and rich industrial experience, we offer a wide range of DM Plant. We use sophisticated technology and machinery in the process of manufacturing these DM plants. These plants are technically designed with precision to save water and it is easy to install. Moreover, these plants are capable of removing all the mineral content from the water by ion exchange. Our range of demineralization plants is available in different sizes and colors to suit the demands of our clients spread all over the world. Ozone Generation Usage : 1. For community Purpose In rural areas 2. For residence, housing, office building Purpose 3. For school, collage, educational institutes Purpose 4. For hotels, restaurants, resorts Purpose 5.For hospitals, nursing homes and others medical institutes Purpose. 6. For Municipality water supply, Corporation Purpose 7. For Industrial purpose like paper mills, cotton mills, Poultry Firms, Chemical plant, Pharmaceutical purpose etc. We also provide customized solutions for any sort of water related problems

RO Filtration Plant

Get Price Quote

For community Purpose In rural areas 2. For residence, housing, office building Purpose 3. For school, collage, educational institutes Purpose 4. For hotels, restaurants, resorts Purpose 5. For hospitals, nursing homes and others medical institutes Purpose. 6. For Municipality water supply, Corporation Purpose 7. For Industrial purpose like paper mills, cotton mills, Poultry Firms, Chemical plant, Pharmaceutical purpose etc. We also provide customized solutions for any sort of water related problems.

Water Demineralizer

Get Price Quote

Detail : Two PVC columns fixed on a wooden frame filled up with Cation & Anion resins of higher exchange capacity. An extra column of Buffer maintains the PH of output water. Acid and Alkali proof pot is also provided to enable the regeneration of the system.Zeolite Standard Demineralizer : Non Electrical Takes less place Easy to install Required less pressure to work

DM Plant

Get Price Quote

We are offering dm plant. The process of extracting mineral salt from water by ion exchanging procedure is called as dm or demineralization. It is known as deionisation also. Conventional distillation is used in various places to remove this salt but with the advancement of technology it is becoming fast obsolete. By taking its place, demineralisation system is used in natural source of water to produce a high quality water.

Demineralisation Plant

Get Price Quote

We are a distinguished manufacturer and supplier of Demineralisation Plant. This appliance has extensive applications in thermal plant, pharmaceutical research laboratories, hospitals, silvering units, chemical industries, distilleries, college laboratories, electroplating works, storage of batteries and food processing units. The Demineralisation Plant consists of necessary parts like degasser, buffer or mixed bed exchangers, rubber lined valves, pipelines, ejectors, regeration tanks and so on. As part of its working system, contaminated water enters first into the Anion Exchanger and exchanges all its Anions with the help of Anion Exchange Resins. On the next level, water enters the buffer or mixed bed and transforms into mineral free water. The degasser part eliminates CO2 and alkali of water. The other important information about our standard quality product include.

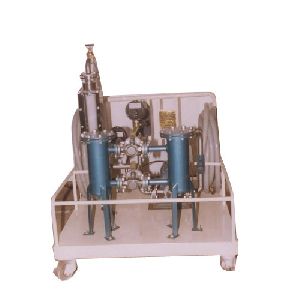

Oil Filtration Plant

Get Price Quote

Application:- These filters are generally used for Oil Filtration Plant system.

Demineralization Plants

Get Price Quote

Manufacture and supply of Industrial DM Plant which includes as Industrial DM Plant, Mix Bed Plant Pharmaceutical and D.M. Plant. Water Demineralization System is process to remove ionic material from water. These process follow get pure water .Demineralization take place in an ion exchange unit called as DEIONIZER that consist of caution bed, an anion bed and mixed bed in series. The mixed bed consist of both caution provide highest iron removal efficiency. » Water Distillation Plant

Water Filtration Plant

Get Price Quote

Owing to the support of our team members, we have been able to provide our valued clients with the technically advanced Water Filtration Plant. Our team members precisely develop Water Filtration Plant keeping in mind industry laid parameters. Water Filtration Plant removes dissolved suspended and colloidal impurities from water by passing through it porous media and make it suitable to drink. Benefits : Beneficial minerals are not removedEnvironmentally friendlyEconomical disinfection process Application areas : Soft DrinksMineral WaterCosmetic ManufacturingFish HatcheriesPharmaceuticalsFood Industries Depending upon the direction of flow through filter, these are designated as : Down flowUp flowBi-flowRadial flowHorizontal flow filters. Based on filter media and bed, filters has been categorized into : Pressure Sand filter or mono-media filterMulti media filterDual media filterActivated Carbon filterIron Removal FilterArsenic Removal FilterScreen Filter System Based on driving force and pressure filter can be : Slow Sand FilterRapid Sand FilterPressure Sand Filter Green Water provide a wide range of Water Filter Plant for the different applications like Water Pre-treatment, surface water treatment, Tertiary filter, cooling tower side stream filter etc.

Water Demineralization Plant

Get Price Quote

STANDARD DEMINERLISERS ARE BASED ON ION EXCHANGE PROCESS UP FLOW TYPE MANUALLY OPERATED, READY TO INSTALL, IN ORDER TO GET HIGHEST EFFICIENCY. OUR DEMINERLISERS ARE DESIGNED ON NEW PROVEN TECHNICAL COUNTER CURRENT REGENERATION SYSTEM. THIS MEANS THAT WATER FLOW THROUGH THE UNIT IS COUNTER CURRENT TO THE REGENERATION CHEMICAL SOLUTION.EASY TO INSTALL AND OPERATE WITH LOW COST MAINTENANCE, HIGH CAPACITY BEAD TYPE CATION AND ANION RESINS ARE USED WHICH IS REMARKABLY STABLE AND HAS A LONG LIFE, CONSISTENT TREATED WATER QUALITY WITH LOWER COST OF REGENERATES, DEMINERLISERS ARE USEFUL FOR PHARMACEUTICALS, CHEMICAL, ELECTROPLATING, INDUCTION FURNACE AND INDUSTRIES WHICH NEEDED LAW TDS WATER FOR THEIR REQUIREMENT.

DM Plant

Get Price Quote

The process of extracting mineral salt from water by ion exchanging procedure is called as DM or demineralization. It is known as deionisation also. Conventional distillation is used in various places to remove this salt but with the advancement of technology it is becoming fast obsolete. By taking its place, demineralisation system is used in natural source of water to produce a high quality water.

demineralization water plant

Get Price Quote

To meet the variegated demands of the clients, our company is instrumental in offering excellent quality range of Demineralization Water Plant. Features: Sturdy construction Shear strength Dimensional accuracy

Water Filtration Plant

100,000 Per Piece

Water Demineralization Plant

155,000 Per unit

Demineralizers

Get Price Quote

Demineralizer is a process of removing ions as well as dissolved solids and gases from water. These comprises of Sodium, Calcium, Magnesium (Cations) and Sulfates, Alkalinity, Chlorides, Carbon-Dioxide, Silica (Anions). For the safety of the clients, we manufacture high grade Demineralizers which are widely used in various industries for its high performance and effectiveness. Features Simple operationLow cost of productionGuaranteed specified heat and electricityWithout heat and electricityQuality conforms to purified water as per I.P Applications Thermal plantsPharmaceuticals researchLaboratoriesHospitalsSilvering unitsChemical industryDistilleriesCollege laboratoriesElectroplating worksStorage batteriesFood processing units

Water Demineralization Plant

80,000 Per Piece

1 Piece(s) (MOQ)

Demineralized Water System

Get Price Quote

We are trustworthy manufacturer, exporter and supplier of Demineralization Plant, (DM Plant) which is duly tested by our experts on different parameters of quality so that the perfect range is delivered to the clients. The Demineralization Plant (DM Plant) is in high demand among the clients. Our product Demineralization Plant (DM Plant) is precisely designed by our team of experts maintaining the market standards.

Mixed Bed DM Plant

Get Price Quote

Mixed Bed DM Plant, STATUS Chimneys, Kenmore Supper Purifier, Nano Purifier

DM Plant

Get Price Quote

We are prominent suppliers of dm plant with affordable prices.

ion exchange plant

Get Price Quote

ion exchange plant, Screening plant, Plastic Reprocessing Plant

Water Filtration Plant

Get Price Quote

Water Treatment Plants, Water Filter, Water Softeners, Industrial Chemicals

Demineralizers

Get Price Quote

Demineralizers, Mineral Water Plants, Ultraviolet Water Treatment System

Demineralisation Plant

Get Price Quote

Demineralisation Plant, Packaged Drinking Water Plant, Iron Removal Plant

Dm Water Plant

Get Price Quote

Industrial Water Filters, Arsenic Removal Plant, Iron Removal Media

ion exchange plant

Get Price Quote

ion exchange plant

DM Plant

Get Price Quote

DM Plant, Iron Removal Filters, dm plant service, Installation

Dm Plants

Get Price Quote

Dm Plants, Industrial Filters, Industrial Water Softeners

Demineralization Plant

Get Price Quote

Demineralization Plant, Installation services, Erection Services