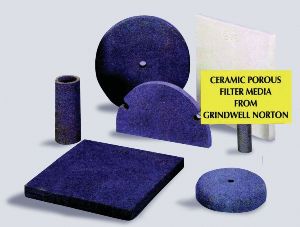

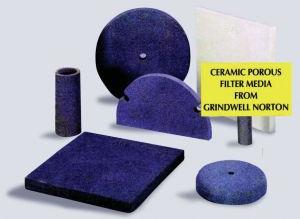

Porous Tiles(Ceramic)

S S Fluidizing Pad S S Fluidizing Pad S S Fluidizing Pad DSC S S Fluidizing Pad Bag-Filter S S Fluidizing Pad S S Fluidizing Pad Fabric Expansion Joint Fastners Fastners High Efficiency Pleated Bag Filter REF Air drc4 Ex Joint Ex Joint Ex Joint Ex Joint Ex Joint Rubber Ex Joint Rubber Fabric Joint Fabric Joint Filter Insulator Insulator Insulator Insulator Insulator Insulator Mechanical Seal Mechanical Seal Mechanical Seal Mechanical Seal Mechanical Seal Mechanical Seal Mechanical Seal Mechanical Seal Mechanical Seal Product S S Fluidizing Pad S S Fluidizing Pad S S Fluidizing Pad DSC S S Fluidizing Pad Bag-Filter Category Fluidizing Filter Media Densified Reinforced Composite (DRC) Industrial Filter Insulator Refectories/Monolithics Expansion Joint We're Here Porous Tiles(Ceramic) APPLICATIONS for separation of suspended solids from acidic, alkaline, corrosive hot liquids and gases that cause a high degree of abration, Grindwell norton has introduced a remarkable product to the Indian industry – Ceramic porouse filter media.Ceramic porouse filter media is an inert body of fused alumina grains, bonded together with an aluminious glass bond at high temprature. the vital aspect of the homogeneity of “pores” in the body structure is attained by a special process, which in trun ensure optimam product performance during use. Ceramic porouse filter media is totaly stable up to 900° C (due to the high refractoriness of alumina) and being chemically inert in nature, does not react with the majority of acids and alkalies.Separation of Solid from Acidic, alkaline, corrosive hot liquids and gases:Grindwell’s ceramic porouse filter media has proved to be the most efficent and cost effective products for this critical application. This makes it ideal for use in a host of user industries like Chemical and Dyeatuff, Fertilizer, Refineries, Petrochemicals, Pharmaceuticals, Cement, Distilleries etc. Grindwell has the capability to custom make various shapes and sizes in the required grade of permeability and porosity to suit in the required grade of permeability and porosity to suit the diverse applications of different customers.How it works: Filteration takes place in a nutache. Ceramic Porous Media is placed inside at some distance above the nutsche bottom, supported by bricks and joined with acid proof cements. Slurry is provied into the nutsche. Ceramic Porous Media allows the liquid (filtrate) to pass thought to the botom of the tank, while the solids (substrate) remain on its surface. The filtered liquid is than carried away by pipes. Filter media is equally effective in open type filter nutsches as pressure nutsches. Beside,Ceramic Porous Media also finds application in aeration and neutralisation in Effluent Treatment Plants and Fluidisation in Boilers, Cement soils and Ash handling in thermal power plants.

...more

Non Woven Filter Bags

Filter bag form the core of any collector and it is here that we have put in our expertise. The product quality is consistently maintained right from the stage of procurement of the base fibre till the time of fabric manufacture. The filter bag are stitched according to the customer’s requirement with sate of the art stitching machines. Filter bag are used in a number of industries such as: Cement, Steel, Incinerators, Boilers, Power Station, Salt Processing, Ceramic, etc.

...more

Filter Bag Cage

We are offering our entire range of products in excellent quality packaging to guarantee zero damage during transit. For this, we have hired only professional packing personnel to ensure the same. We have superior storage capacity to safely store the extensive product range that we offer. Our massive and well-maintained storage space is well-connected with the shipping unit.

...more

Dust Collector Bags

Filter bag form the core of any collector and it is here that we have put in our expertise. The product quality is consistently maintained right from the stage of procurement of the base fibre till the time of fabric manufacture. The filter bag are stitched according to the customer’s requirement with sate of the art stitching machines. Filter bag are used in a number of industries such as: Cement, Steel, Incinerators, Boilers, Power Station, Salt Processing, Ceramic, etc.

...more

dust collection filter

Filter bag form the core of any collector and it is here that we have put in our expertise. The product quality is consistently maintained right from the stage of procurement of the base fibre till the time of fabric manufacture. The filter bag are stitched according to the customer’s requirement with sate of the art stitching machines. Filter bag are used in a number of industries such as: Cement, Steel, Incinerators, Boilers, Power Station, Salt Processing, Ceramic, etc.

...more

ceramic stone

Combining outstanding quality and value, our organization is manufacturing and exporting a wide range of optimum quality floor tiles. in this range, we offer designer floor tiles, vitrified floor tiles, rustic floor tiles, glossy floor tiles, satin floor tiles, kitchen floor tiles, etc.

...more

Ceramic Cloth

Ceramic porouse filter media.Ceramic porouse filter media is an inert body of fused alumina grains, bonded together with an aluminious glass bond at high temprature. the vital aspect of the homogeneity of “pores” in the body structure is attained by a special process, which in trun ensure optimam product performance during use. Ceramic porouse filter media is totaly stable up to 900° C (due to the high refractoriness of alumina) and being chemically inert in nature, does not react with the majority of acids and alkalies.Separation of Solid from Acidic, alkaline, corrosive hot liquids and gases:Grindwell’s ceramic porouse filter media has proved to be the most efficent and cost effective products for this critical application. This makes it ideal for use in a host of user industries like Chemical and Dyeatuff, Fertilizer, Refineries, Petrochemicals, Pharmaceuticals, Cement, Distilleries etc. Grindwell has the capability to custom make various shapes and sizes in the required grade of permeability and porosity to suit in the required grade of permeability and porosity to suit the diverse applications of different customers.

...more

ceramic block

We produce the entire range of products by making use of quality-approved raw materials sourced from the trusted vendors present in the market. Also, the inputs are cross checked by our quality experts. Our product is packed in industrial grade packages that are recyclable and provide protection to the products from physical and chemical damage. Additionally, the product is properly labeled to provide information.

...more

Aeration Pad

It helps in getting uniform flow and discharge of dry bulk materials through minor vibration & aeration. It Prevents bridging, rat holing and compacting in storage silos, dust collectors, weigh bins and in other storage equipments. These pads are available in number of material to overcome the problems like high temperature, High abrasion& Food Grade.

...more

Channel Induction Furnaces

Be first to Rate

Rate ThisOpening Hours