ZM250 Single Phase Tig Welding Machine

Parameters ZA-630 ZA-1000 ZA-1250 Mains supply voltage, Ph/Vac (Tolerance) 3-Ph/415V (-15% +15%) 3-Ph/415V (-15% +15%) 3-Ph/415V (-15% +15%) Open circuit voltage, Vdc (max) 71.5 71.5 71.5 No load power, W ≤100 ≤100 ≤100 Output current range, A 160-630 160-1000 160-1250 Duty Cycle % 100 100 100 Dimension (LxWxH) mm 690x355x965 690x355x965 690x355x965 Weight, kgs (approx.) 70 98.5 98.5

...more

Welding Machine

Specialities : Quality approved, High performance ,Light weight

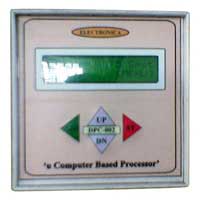

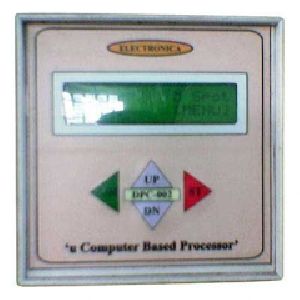

welding controller

We are among the leading Welder Controller Manufacturers in India. We manufacture superior quality Welding Controller that is used in different industries. These are very efficient to work at any range of voltages. They are featured with soft start and smooth handling. The Resistance Welding Controller of our company is unrivaled in the market due to its high performance and durability. These have all the features to meet the international standard of quality. They consume very less electricity as compared to the other welding controller. In spite of a very high standard of quality, we have kept the price of our products within control. Specification of Resistance Welding Controller Using Micro Computer Mode Available : Spot (Single & Repeat), Seam, ProjectionMaximum 1000A SCR (Back to Back) can be triggered using this type of controller.Control using pulse transformer (Multiple Pulse Firing Technique to Reduce the Gate Loss of High Power SCR.)Close loop PI control (Optional) available on demand.Open loop % current control inbuilt.Solenoid valve output 24V @2A (max).Motor enable 24V@1A (For Seam Welding).Thermostats function for detection of overheating and switch off the m/c.Pressure switch & water switch input optional. Parameter of The Controller Pre-Sqz Time : 0 to 99 CycleSqz Time : 0 to 99 Cycle Weld Time Pre Heat : 0 to 99 CycleMain Heat : 0 to 99 CyclePost Heat : 0 to 99 Cycle1st Cool : 0 to 99 Cycle2nd Cool : 0 to 99 Cycle3rd Cool : 0 to 99 CycleHold Time : 0 to 99 CycleOff Time : 0 to 99 Cycle Current Pre Heat Current : 10% to 99%Main Heat Current : 10% to 99%Post Heat Current : 10% to 99%Input of The Controller : 230-500v AcInbuilt 24V dc power supply for solenoid valve or other device power supply.

...more

Water Cooled Welding Machine

Welding Machine Specification Mains supply voltage , Ph/VAC , V 3/415 –20% … +15% Mains supply frequency, Hz 50/60 Open circuit voltage VDC (max), V 78 Energy saver In-built Welding current range, A (TIG/MMA) 50– 500 Load Capacity at 400C 60% Duty Cycle, A (TIG/MMA) @6Hrs 630 100% Duty Cycle, A (TIG/MMA) @6Hrs 450 Input power 100% Duty Cycle, kVA 25 (TIG/MMA) Power factor at 100% Duty Cycle 15 (TIG/MMA) Efficiency at 100% Duty Cycle ≥ 87% Control Panel Features Digital Display (Voltage & Current) YES Cooling Water Cooled Protection class IP23S Insulation class (main transformer) H Dimensions(app.), LxWxH, mm 590x305x565 Weight(app.), Kg 42 IEC 60974-1,IEC 60907-10 Conformance YES Pump Specification MODEL NO:MCUP-50 (Single Phase) Mains supply Voltage, V 380 Mains supply Frequency, Hz 50/60 Power Consumption, kW 0.37 Insulation Class F Flow Rate(Max), Lit/Min 8 Water Height, Mt 30 Power, HP 0.5 Cooling Capacity, W 1500 Dimensions (app.), LxWxH, mm 690x315x250 Weight (app.), Kg 16

...more

SUB MERGED ARC WELDING MACHINE

ZM200/ZM250 are single phase & ZM260 is 3-phase inverter welder for MMAW and TIG (Lift TIG). These can burn MMA electrodes of any class. Soft Arc Start is available for smooth starting of TIG in Lift TIG. All the machines are suitable for continuous use of 3.15/4.0/6.3 mm MMA Electrodes.

...more

Solar Inverter

We are among the prominent Solar Electric Inverter Manufacturers and Suppliers in India. We manufacture Solar Inverter (up to 10 KVA@360vbus) of premium quality. They are very efficient to convert the solar energy to electrical energy. As the whole country is facing the crisis of electrical energy, it is a very popular substitute. These are totally pollution free in nature. The Solar Power Inverter we produce is very much in demand due to the performance it offers. They are very much durable in nature and quite affordable as compared to the products of other companies. Specifications of 10 Kva Sine Wave Invertor Using Micro Controller Off Line TypeSineosodal Wave FormLed Indicator For Fault And Status Display.8KW Continuous.Creast Factor 1:3 for 10MS Duration.THD Less Than 5 %Over Load At 120% of 8KW.No Load Loss Less Than 5%Efficiency DC to AC 91%(MAX)Efficiency AC to AC 97%(MAX)O/P Voltage 230V+/- 2%(Invertor ModeO/P Frequency 50HZ +/- 0.01%Input 192V DC(BAT)Over Voltage Shutdown 235VUnder Voltage (BAT) Alarm 170V .(APPOX)Bat Deep Discharge Shutdown 162V(APPOX)Full Igbt Controlled.Inbuilt SMPS Based Charger @20A(MAX).PF At Charging 0.9(MAX) With No Load.Wide Voltage Charging Window(140V-270V)Change Over Time 100MS.Auto Bypass When Invertor Not WorkingSoftstart for Smooth Operation Of Load.Bat Reverse Protection.O/P Short CKT ProtectionOver Temp ProtectionClass H Insulation.Dual Fan for Individual Hotbody Cooling.Temp Dependent Fan Enabling, For Unnecessary Power Loss.

...more

seam welding machines

We are engaged in manufacturing and supplying welding equipment such as multi process inverter welder (cvcc), multi operator inverter welder, inverter mmawtig welder and inverter welding machine.

...more

resistance welding controller

Specification of Resistance Welding Controller Using Micro Computer · Mode Available : Spot (Single & Repeat), Seam, Projection · Maximum 1000A SCR (Back to Back) can be triggered using this type of controller. · Control using pulse transformer (Multiple Pulse Firing Technique to Reduce the Gate Loss of High Power SCR.) · Close loop PI control (Optional) available on demand. · Open loop % current control inbuilt. · Solenoid valve output 24V @2A (max). · Motor enable 24V@1A (For Seam Welding). · Thermostats function for detection of overheating and switch off the m/c. · Pressure switch & water switch input optional. Parameter of The Controller · Pre-Sqz Time : 0 to 99 Cycle · Sqz Time : 0 to 99 Cycle Pre Heat : 0 to 99 Cycle · Main Heat : 0 to 99 Cycle · Post Heat : 0 to 99 Cycle · 1st Cool : 0 to 99 Cycle · 2nd Cool : 0 to 99 Cycle · 3rd Cool : 0 to 99 Cycle · Hold Time : 0 to 99 Cycle · Off Time : 0 to 99 Cycle Current · Pre Heat Current : 10% to 99% · Main Heat Current : 10% to 99% · Post Heat Current : 10% to 99% · Input of The Controller : 230-500v Ac · Inbuilt 24V dc power supply for solenoid valve or other device power supply.

...more

portable induction heater

Multi Operator Inverter Welder

Z-2406(X) is a 2400A multi operator inverter welder, which contains 6 nos. 400A inverter based MMAW/TIG welders in a compact sheet metal housing mounted on rubberized wheels for the ease of transportation. Up to 6 nos. welders can operate simultaneously using Z-2406(X).Connected to the mains supply through common distribution board and provided with smart energy manager to indicate current, voltage and pf under load / no load. Each power source is VRD enabled and is suitable for welding with long lead. This is an ideal solution for railway workshops and shipyards.

...more

MMAW/ SCRATCH TIG WELDING MACHINES: 3-Phase

Z-400 series machines are 400A IGBT based inverter mmaw/tig welder. MMAW/TIG (Lift TIG) suitable for all weather indoor and outdoor welding applications. Lightest among the Indian manufacturers (415A power source weighs 20Kgs only) and coupled with a robust sheet metal design makes it a preferred choice of the welders. It is equipped with all the essential features for MMAW - anti stick, arc force and hot start to handle MMA electrodes of any class - basic, rutile or cellulosic up to 6.3 mm size. The micro-controller based design ensures consistent performance for any class of electrode even at worse power conditions - input voltgage as low as 360V or as high as 480V. In-built protections are provided against thermal overloading, single phasing, over/under voltage and harmonics. Pf is close to unity and saves electricity up to the extent of 40 to 50% over the conventional rectifiers.

...more

MMAW/ SCRATCH TIG WELDING MACHINE (Economic Version): Z400E

ZM200E is single phase inverter welder for MMAW and TIG (Lift TIG). These can burn MMA electrodes of any class. Soft Arc Start is available. It can burn up to 6.3mm MMA Electrodes.

...more

mag welding machines

We are engaged in manufacturing and supplying welding equipment such as multi process inverter welder (cv/cc), multi operator inverter welder, inverter mmaw/tig welder and inverter welding machine. ZM-4000/5000/7200 are 400/500/720 multi-process inverter welder (CV/CC) based power sources for MIG/MAG, MMAW and TIG. The micro-controller based power sources delivers outstanding welding performance and are suitable for welding in all positions. All key features for MIG/MAG welding e.g. 2/4 track welding, wire inching, gas purging and burn back are available with ZM-series power sources. ZM-4000 is recommended for continuous MIG/MAG welding with 1.2 mm wire and ZM-5000 is recommended for continuous MIG/MAG welding with 1.6 mm MS/SS/Al/FC wire. Both ZM-4000/5000 are suitable for MMA welding with up to 6.3 mm electrodes of any class and TIG welding with Lift TIG. ZM7200 is recommended for heavy duty gurder application.

...more

inverter welding machine

inverter dc welding machine

GTAW WELDING MACHINE

Z-200T/ Z-300T/ Z-630T are inverter welder for DC TIG, Pulse TIG & MMAW. These can burn MMA electrodes of any class & welding in any position. Soft Arc Start is available for smooth starting of TIG in Lift TIG. These machines are lightweight yet sturdy construction.

...more

ENERGY SAVING CUM VOLTAGE REDUCER DEVICE

n a Welding rectifier, the primary winding of the transformer is always energized. Even if welding is not going on, the machine always draws some current from the supply to meet the no load losses. Although arc welding can be performed safely, there are circumstances where there is a substantial risk of electric shock where workers need to weld in tight areas where heat and humidity can be a factor. The severity of the shock received when a person becomes part of an electric circuit is affected by several factors. These include: 1) The amount of current flowing through the body of the person. 2) The path of the current through the body, and the length of time the body is in the circuit. 3) The current level (measured in mA, milli-amperes) is a function of both the voltage at the electrodes and the resistance of the person's body. This energy saving cum voltage reducing device is designed to operate on any constant DC current welding machine (stick welder) with an open circuit voltage of 60 - 100 volts. Until the arc is struck the output voltage is maintained lesser than 12 volts. This prevents the operator from receiving a shock. Also the input supply to primary of transformer is cut when the output voltage is 12V, hence there is no power loss during this idle condition. Thus it performs energy saving action. About Energy Saving cum Voltage reducing device and its working principle: This device is connected between the input supply of the welding rectifier and it continuously monitor the welding output terminal voltage. On striking the arc, full selected output is available instantaneously. Energy saving cum voltage reducing device senses the stoppage in welding and cuts off the supply to the primary winding within the predetermined time (approx. 30 second to 5 minute) and safe voltage of 12 Volts will be appeared on the Welding terminals until the next arc strike. This device reenergizes the primary winding instantly without affecting the welding quality as soon as the electrode comes in contact with the job. APPLICATIONS SALIENT FEATURES · Energy Saving application. · Confined Spaces such as vessels, mine shafts · Wet or damp conditions. · Hot and humid conditions. · Working at heights. · Safe voltage to protect from electric shock when welding is not going on. · Instant Start of welding operation · Reduction in machine heating · Compact assembly. · Easy for mounting. · Welding performance unaffected

...more

drawn arc stud welding machines

DA series welding machines are Inverter based welder for STUD welding. These machines are equipped with highly efficient microcontroller. Multiple program for various welding can be stored in its memory.

...more

drawn arc stud welding machine

Electronica India is one of the leading Drawn Arc Stud Welding Machine Manufacturers in Kolkata (W.B.). Our Drawn Arc Stud Welding Machine features advanced ZVS technology with highest efficiency, thus it is widely praised for its effective performance. Our Drawn Arc Stud Welding Machine is ideal for site applications. Features Advance ZVS technology with highest efficiency.High power factor 0.95 at full load.Advance dynamics controls for batter arc stability.Support up to 30 mtrs cable length (T.C applied).Duty cycle 20% @ 10 min at 40°C.Generator compatible Wide input voltage fluctuation tolerant Ideal for site application.Module IGBT basedMicroprocessor basedShipped with TWI compatible damper Gun for deck sheet welding upto 25 mm shear stud.One set chuck is compliment y with every machine.

...more

CC/CV MIG/ MAG WELDING MACHINES

ZM200/ZM250 are single phase inverter welder for MMAW and TIG (Lift TIG). These can burn MMA electrodes of any class. Soft Arc Start is available for smooth starting of TIG in Lift TIG. All the machines are suitable for continuous use of 3.15/4.0/6.3 mm MMA Electrodes. These machines are highly energy efficient & extremely low input demand.

...more

ARC Welding Transformer

ZM200ZM250 are single phase & ZM260 is 3-phase inverter welder for MMAW and TIG (Lift TIG). These can burn MMA electrodes of any class. Soft Arc Start is available for smooth starting of TIG in Lift TIG. All the machines are suitable for continuous use of 3.154.06.3 mm MMA Electrodes.

...more

Induction Heaters

portable inverter welding machine

resistance welding controller

Be first to Rate

Rate ThisOpening Hours