WATER WASH PAINTING BOOTH

We are offering water wash painting booth. Pump water-wash booths are often chosen when there is heavy painting or pigment overspray. It allows continuous operation with minimum of down time for maintenance.

...more

SIDE DRAFT SPRAY PAINTING BOOTH

Offers side draft spray painting booth. These spray paintings booths meet most of the industrial finishing requirements. The fresh air flows from behind the operator; across the component towards the extraction chamber. That is reason, they are known as side draft spray painting booths.

...more

PRESSURISED DOWN DRAFT PAINTING BOOTH

The Side Downdraft booth offers most of the full downdraft booth benefits without an expensive pit. Fresh air is brought in from the clean upper levels of the shop, through filter banks in the ceiling of the booth. The clean filtered air is drawn down and away from the product through exhaust filters at floor level along both sides of the booth. The over spray is pulled away from the product and away from the painters. This booth is equipped with an air supply plenum and is available in both solid back and drive through designs. The Downdraft booth offers most efficient airflow. Fresh air is brought in from the clean upper levels of the shop, through filter banks in the ceiling of the booth. The clean filtered air is drawn down and around the product through exhaust filters in the pit in the floor of the booth. The over spray is pulled around the product and away from the painters. This booth is equipped with an air supply plenum and is available in both solid back and drive through designs.

...more

Powder Coating Machines

Gallant Offers "Concept - to - Completation" service from initial Specification, Design, Project Development, Manufacture, Installation & Commissioning. We offers a full product line of equipment and systems designed to meet a wide variety of demanding production requirements. From relatively simple manual systems to sophisticated, programmable, automatic recovery systems for improves efficiency, flexibility and productivity. The latest state of art CAD technology accompanied with a team of skilled, Well qualified & experience engineers, combine to deliver a professional and proved solution to any application through the Design, Manufacturing & onto the installation & final Commissioning at site.

...more

Powder Coating Booth

We are offering powder coating booth. Various ranges of industrial powder booths are based on a modular concept, which enables each booth to be customized to suit any specific requirement.

...more

NON-PRSSURISED DOWN DRAFT PAINTING BOOTH

The Water Wash Booth is unique booth working on the principle of cyclonic separation of water from the air stream when the paint laden air streams strikes the cyclonic profile plate. The suction is from below the back wall & the turbulence of waves caused at the inlet of toothed plate causes the surface to shear & is entrained by the water. Over spray of paint mixed with air is drawn into the air water mixture and violently scrubbed in an area of extreme turbulence caused by sharp changes in the direction of air Liquid Spray. DOWN & SIDE - DRAFT BOOTHS The Side Downdraft booth offers most of the full downdraft booth benefits without an expensive pit. Fresh air is brought in from the clean upper levels of the shop, through filter banks in the ceiling of the booth. The clean filtered air is drawn down and away from the product through exhaust filters at floor level along both sides of the booth. The over spray is pulled away from the product and away from the painters. This booth is equipped with an air supply plenum and is available in both solid back and drive through designs. The Downdraft booth offers most efficient airflow. Fresh air is brought in from the clean upper levels of the shop, through filter banks in the ceiling of the booth. The clean filtered air is drawn down and around the product through exhaust filters in the pit in the floor of the booth. The over spray is pulled around the product and away from the painters. This booth is equipped with an air supply plenum and is available in both solid back and drive through designs.

...more

MANUAL SERIES Powder Coating Machine

Offers 100 kv electrostatic powder coating machine combine production-proven powder spray, gun & control technology and performance suitable for all type of jobs with low and mass volume in any batch & conveyorised system.

...more

Liquid Painting Booth

Our Paint Booth can meet all your requirements. The Spray Painting Booth is on simple construction, easy to install and maintain. Normally Paint Booths are made of mild steel components (Value addition can be done by all stainless steel components), it also consists of a highly efficient exhaust blower or blowers to throw thinner in higher altitudes of air.

...more

DOWN DRAFT TYPE SPRAY PAINTING BOOTH

We offers down draft type spray painting booth. These types of painting booths are specially designed for heavy and voluminous components which are difficult to handle; like tractors, chassis of vehicles, trailers, earth moving machineries, wagons etc.

...more

Dip Pre-Treatment Plant

We offer dip pre-treatment plant. This is a conventional pre-treatment wherein the plant cost is less and is suitable for low volume production lines. The chemicals are stored in the msss fabricated tanks.

...more

Curing Ovens

Gallant offers the full range of Powder Liquid curing oven - whether electrical, gas or diesel fired. Whether batch type or conveyorised tunnel type.

...more

Curing & Drying Oven

Our Batch & Conveyorised ovens are available in many standard sizes (custom sizes available on request) and is the ideal choice for Powder Curing, Paint Baking & Other applications. these ovens feature combination airflow arrangement which provides uniform air distribution along the entire length of the work chamber resulting in quality cured finishes and optimum cure cycles. Our powder curing ovens are designed to prevent powder blow-off which reduces rework saving you time and money. These offers excellent temperature uniformity which is a key component in providing you with a consistent, high quality curing results part after part! A low cost replaceable filter can be provided to help eliminate contamination and maintain a clean work chamber. BENEFITS : Heavy duty construction and quality components. Excellent uniformity and heating rates for consistent, high quality curing results. No powder blow-off – reduces rework. Uniform heat distribution provides quality cured finishes and optimum cure cycles. Quick heat-up rates so you can cure more loads per day.

...more

CED Coating machine

Electrocoating, which is also referred to as electro deposition, electrophoretic deposition, CED Coating, CED Painting or electropainting, is an organic finishing process that uniformly applies thin-film primers and one-coat finishes to metallic substrates. Electrocoating resembles electroplating in that it utilizes an electrical current to deposit a coating onto substrates. However, electrocoating deposits water born paint onto substrates rather than metal ions. The overall process consists of four main process steps: Pre-treating, Electrocoating, Rinsing, and Baking. The electrocoating process may be anodic or cathodic, depending on the charge applied the substrate. Although the processes are virtually the same, properties of the resultant coating are dissimilar. Anodic systems, which were the first to be used for electrocoating, apply paint to positively charged substrates. The negatively charged pigment and resin particles deposit onto the substrate (anode). One disadvantage of this process is that substrate metals dissolve and become incorporated into the coating, which affects surface properties. Cathodic electrocoating deposits paint onto negatively charged substrates and offers several advantages over anodic electrocoating. For example, metal dissolution of the substrate does not occur, cathodic electrocoating has the ability to deposit over contaminants, corrosion resistance is improved, and a better color consistency occurs over welded areas. Automated transporter for timed dipping and transfer of components between different tanks. Barrel configuration available for treatment of a number of small components in one go. Customized transporters available depending on the space availability and application. Automation options available for timed operations, counters, etc.

...more

Automatic Spray pre-treatment

Automatic Spray pre-treatment is the most common system for pre-treatment and therefore recommended where the needed space is available. Features - Effective drain length. Vestibules for overspray and vapor.

...more

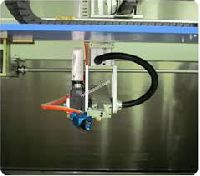

Automatic Reciprocator with Seiving System

We offer Automatic Reciprocator with Seiving System available in a range of sizes, the Gallant reciprocator (GALLAUTO) offers robust construction together with ease of adjustment of the updown stroke through its high speed variable controller.

...more

automatic powder coating machine

Gallant Equipment Pvt. Ltd introduces Automatic Powder Coating Gun with control unit providing unbeatable application quality on any metal surface. It has centrifugal force to ensure uniformity & deep penetration.

...more

Automatic painting machine

Gallant Offers "Concept - to - Completation" service from initial Specification, Design, Project Development, Manufacture, Installation & Commissioning. We offers a full product line of equipment and systems designed to meet a wide variety of demanding production requirements. From relatively simple manual systems to sophisticated, programmable, automatic recovery systems for improves efficiency, flexibility and productivity. The latest state of art CAD technology accompanied with a team of skilled, Well qualified & experience engineers, combine to deliver a professional and proved solution to any application through the Design, Manufacturing & onto the installation & final Commissioning at site.

...more

Automatic and Manual Powder Coating Equipment

Gallant Offers "Concept - to - Completation" service from initial Specification, Design, Project Development, Manufacture, Installation & Commissioning. We offers a full product line of equipment and systems designed to meet a wide variety of demanding production requirements. From relatively simple manual systems to sophisticated, programmable, automatic recovery systems for improves efficiency, flexibility and productivity. The latest state of art CAD technology accompanied with a team of skilled, Well qualified & experience engineers, combine to deliver a professional and proved solution to any application through the Design, Manufacturing & onto the installation & final Commissioning at site. We manufacture highly efficient Powder Coating Plants, which meets the requirements of the customers accordingly. We ensure that latest technology is employed and are appreciated for their corrosion resistance, durability, precision designing, easy installation, optimization of energy & space, easy cleaning and cost effectiveness. These are available in various sizes. Powder Coating Plant is made by quality approved materials that is purchase from leading vendors of the market. We also check these products on various quality parameters. Modular Construction With Appropriate Booth Size. Appropriate Pre-heating, Curing & Drying Ovens. Appropriate Material Handling System. (Manual, Automated) Single or Multiple Cyclone upto 90% Powder Recovery. Optional Cartridge or Pulse-Jet Cartridge Recovery System. Safety Interlocking & Emergency Stops. Centralized Control Panel for Entire Plant. Environmental & Fire Norms Compliant. Prompt & Continuous after Sale Support.

...moreBe first to Rate

Rate ThisOpening Hours