Zinc Anodes

They are made from a metal alloy with a more “active” voltage (more negative reduction potential more positive electrochemical potential) than the metal of the structure. The difference in potential between the two metals means that the galvanic anode corrodes, so that the anode material is consumed in preference to the structure.

...more

Titanium anodes

Electrodes (Anodes) consist of a basic component, which is responsible for mechanical stability and uniform current distribution. As Titanium has all these characteristics, insoluble electrodes are manufactured with titanium as basic component. The excellent stability of mixed metal oxide (MMO) coated titanium anodes have been used for almost 30 years. MMO coated titanium anodes are used in various environments such as seawater, brackish water, fresh water, carbon backfill, and concrete. However, many structure owners and CP engineers use MMO coated titanium anodes only specify the sizes without understanding the characteristics, limitations and evaluation method of the anodes. There are many different size and shapes are available, wire, ribbon, mesh, expanded mesh, rod, tubular, disc, probe etc.

...more

Thermit Welding Equipments

Also known as exothermic welding, and thermit welding, is a welding that employs molten metal to permanently join the conductors. The process employs an exothermic reaction of a thermite composition to heat the metal, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminium powder and a metal oxide. In exothermic welding, aluminium dust reduces the oxide of another metal, most commonly iron oxide, because aluminium is highly reactive. 3 C u 2 O + 2 A l ⟶ 6 C u + A l 2 O 3 {\displaystyle \mathrm {3\ Cu_{2}O+2Al\longrightarrow 6\ Cu+Al_{2}O_{3}} } Thermite welding is widely used to weld railway rails. Thermite welding is also use to making electrical connections to steel and ductile iron pipelines as well as other metallic structures, which are to be cathodically protected or electrically earthed.

...more

Stainless Steel Junction Box

Junction boxes for positive and negative current distribution and control , and for resistance bonding are available to meet exact client specifications. Suitable for onshore and marine environments in safe and hazardous areas. When specifying a Cathodic Protection Junction Box assembly please clarify specific hardware and components required. Type of Enclosure: Stainless Steel 316L & 304, Aluminium Explosion Proof, Painted Mild Steel Plastic GRP, Galvanized and Painted Cast Iron Custom Finishes, Please also specify IP, NEMA or Hazardous area classification requirement.

...more

Reference Electrode

a reference electrode is an electrode which has a stable and well-known electrode potential. The high stability of the electrode potential is usually reached by employing a redox system with constant (buffered or saturated) concentrations of each participants of the redox reaction. There are many ways reference electrodes are used. The simplest is when the reference electrode is used as a half cell to build an electrochemical cell. This allows the potential of the other half cell to be determined. there are many types of reference electrodes: aqueous reference electrodes, non-aqueous reference electrodes, pseudo-reference electrodes etc. Mostly the aqueous reference electrodes are in use for potential measurement.

...more

Pin Brazing

Pin brazing is an easy, metallurgically safe method of making electrical connections to steel and ductile iron pipelines as well as other metallic structures, which are to be cathodically protected or electrically earthed. The pin brazing technique is based primarily upon Electric-arc silver soldering using a specially designed portable pin brazing unit, a hollow brazing pin containing silver solder and flux. The brazing process is initiated by depressing a trigger on the brazing gun. This, as with most forms of electrical welding, simply completes a circuit through which a DC current is passed. The pin tip is the point of highest resistance at which point an arc is drawn, melting the solder flux whilst simultaneously heating the lug material and the surface of the structure or pipeline to the required soldering temperature. After approximately 1.5 seconds the circuit is mechanically or electronically broken, the solenoid is de-energized and the brazing pin is pushed forward into the molten pool of brazing alloy. The pin tip, brazing alloy, flux and lug cool into a homogenous unit.

...more

Oil Cooled Rectifier

Auto Reference Mode The operation of the TRUs in this mode will be fully Automatic and will be controlled by reference electrode feedback .The unit will automatically maintain reference voltage or P.S.P. of the set value under all conditions. Manual Mode The DC output voltage of TRU will be controlled in multiple symmetrical steps by means of a separate Auto/manual transformer with Coarse & Fine tapping. CVCC Mode The unit will be operated in Constant Voltage or Constant Current mode. In constant voltage mode the DC output voltage will be settable from 0 to rated value in stepless manner by means of voltage adjustable pot.

...more

Natural-Air Cooled Rectifier

TRUs impress DC Currents in to the Carbon-steel/steel structure to be protected in opposite direction to the galvanic corrosion currents & protects the structure from corrosion. To obtain the optimum level of protection under varying conditions, it is necessary to vary the impressed current continuously so as to maintain a constant level of protective potential at the structure. This continuous monitoring and control can be achieved by providing an automatic control for the cathodic protection system.

...more

MMO Coated DSA Anodes

Dimensionally Stable Anodes (DSA) Normally, Electrodes (Anodes) consist of a basic component, which is responsible for mechanical stability and uniform current distribution. As Titanium has all these characteristics, insoluble electrodes are manufactured with titanium as basic component. The excellent stability of mixed metal oxide (MMO) coated titanium anodes have been used for almost 30 years. MMO coated titanium anodes are used in various environments such as seawater, brackish water, fresh water, carbon backfill, and concrete. However, many structure owners and CP engineers use MMO coated titanium anodes only specify the sizes without understanding the characteristics, limitations and evaluation method of the anodes. There are many different size and shapes are available, wire, ribbon, mesh, expanded mesh, rod, tubular, disc, probe etc. MMO coatings for cathodic protection are mainly divided into three types, iridium oxide (IrO2-x), ruthenium oxide (RuO2-x) and its mixture. In addition, titanium oxide (TiO2-x) and tantalum oxide (Ta2O5) are also used as the bulk materials. When MMO coated anodes discharge CP current, the coating is slowly consumed. The consumption rates of MMO coatings are varies based on the chemical compositions and the environments. Generally, iridium oxide based MMO coating is mainly used for oxygen evolution and ruthenium oxide coating is used for chlorine gas evolution. Recently, NACE developed and modified the acceleration anode life test method using acid solutions (H2SO4, NaSO4, etc.). Recently, NACE published the life acceleration tests using acid solution. Ruthenium coating is consumed at higher rates under working condition in strong acid solution, it needs to considered in actual anode performance. Iridium MMO coated anode can provide much longer life than ruthenium MMO coated anode with the same thickness when they discharge current in the same environment. The cost of iridium is much more expensive than that of ruthenium; however, iridium MMO coating is typically used when chlorine evolution is concerned.

...more

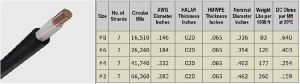

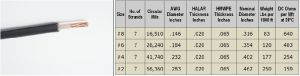

Kynar Cable, HMWPE Cable

Cathodic Protection Cables, Primary Kynar Insulation, HMW (High Molecular Weight) Polyethylene Jacket. Stranded bare copper conductor conforms to ASTM Specification B-8. A homogeneous wall of natural PVDF fluoropolymer (Kynar) shall be extruded over the conductor. An Insulation of high molecular weight polyethylene conforming to ASTM-D-1248, Type 1, Class A, Category 5, Grades E4 and E5. Tensile Strengths Jl, J3. Available with high density polyethylene (Types II, III, IV) Class B and C (all colors). Surface printed. Custom printing available.

...more

Impressed Current Anode

Anodes for ICCP systems are available in a variety of shapes and sizes. Common anodes are tubular and solid rod shapes or continuous ribbons of various materials. These include high silicon cast iron, graphite, mixed metal oxide, platinum and niobium coated wire and other materials.

...more

HMWPE Cable for Cathodic Protection

High Molecular Weight Polyethylene (HMW-PE) Cathodic Protection Cables: 600 Volts, Single Conductor, Stranded Copper. Stranded copper conductor conforms to ASTM Specification B-8. Insulation is high molecular weight polyethylene conforming to ASTM D-1248, Type 1, Class A, Category 5, Grades E4 & E5. Tensile Strengths Jl, J3. Available with high density polyethylene (Types II, III, IV) Class B & C (all colors) Applications: A direct burial DC cable for use in cathodic protection applications such as anode lead wires, header cables, structure connections, test leads and more. The product can also be used for submerged installations in water tanks, offshore structures and other similar applications. The polyethylene insulation is durable, abrasion resistant and flexible but has temperature and chemical limitations.

...more

Halar Cable, HMWPE Cable

Cathodic Protection Cables, Primary Halar Insulation, HMW (High Molecular Weight) Polyethylene Jacket. Stranded bare copper conductor conforms to ASTM Specification B-8. An insulation of homogeneous wall of natural ECTFE fluoropolymer (Halar) shall be extruded over the conductor, jacket insulation is high molecular weight polyethylene conforming to ASTM-D-1248, Type 1, Class A, Category 5, Grades E4 and E5. Tensile Strengths Jl, J3. Available with high density polyethylene (Types II, III, IV) Class B and C (all colors). Surface printed. Custom printing available. Applications: A direct burial cable for use in cathodic protection deep well installations or other situations where resistance to chlorine gas is required. The primary ECTFE (Halar) insulation provides chemical resistance properties. The secondary or outter jacket of high molecular weight polyethylene (HMWPE) provides abrasion resistance.

...more

Galvanic Anode (Sacrificial Anode)

A galvanic anode is the main component of a galvanic cathodic protection (CP) system used to protect buried or submerged metallic structures from corrosion. They are made from a metal alloy with a more “active” voltage (more negative reduction potential / more positive electrochemical potential) than the metal of the structure. The difference in potential between the two metals means that the galvanic anode corrodes, so that the anode material is consumed in preference to the structure. The loss (or sacrifice) of the anode material gives rise to the alternative name of sacrificial anode. There are three main metals used as galvanic anodes, Magnesium, Aluminium and Zinc. They are all available as blocks, rods, plates or extruded ribbon. Each material has advantages and disadvantages

...more

Explosion Proof Terminal Box

Resistors, Metering, Diodes, Shunts Monitoring, Labeling, Copper Links Terminals, unidirectional blocking diodes etc. Support Frames, Security Locking, Pole mount channel, Wall mount tabs or Customer Specifie

...more

Explosion Proof Junction Box

Internal Components: Resistors, Metering, Diodes, Shunts Monitoring, Labeling, Copper Links Terminals, unidirectional blocking diodes etc. Mounting Options & Security: Support Frames, Security / Locking, Pole mount channel, Wall mount tabs or Customer Specified….

...more

EPR CSP Cable

The quality of the cable is extremely important for the efficiency of cathodic protection system, specially the anode cables. Commonly use cathodic protection cables are PVCPVC, PEPVC, EPRCSP, XLPEPVC, XLPEPVCSWAPVC, PVDFHMWPE etc. Cables used for cathodic protection systems must be highly corrosion resistant and capable of withstanding adverse environments to which they are exposed. High Molecular Weight Polyethylene (HMWPE) is suitable for most environments. In saline environment, we recommend KYNARHMWPE or HALARHMWPE cables, which are dual extruded highly chlorine resistant power cables.

...more

dc shunt

Data Logger

In a modern cathodic protection system it is essential to monitor and / or record continuously and precisely the Potential Difference (P.D.) between the protected structure and the environment surrounding it. Data loggers are computerized instruments into which data, control points, and other information can be entered. Some of them are so small they can fit into a ground level test station. After use, data loggers are connected to a computer and the information is downloaded. The computer can also create graphs of data Many new instruments have recently been added to the armoury of those providing cathodic protection. Several of these are given here, which is also concerned with the resistivity of electrolytes and its measurement and the complementary use of insulating coatings and cathodic protection.

...more

Current Interrupter

Current Interrupters are the key instrument to obtain IR free potential (instant Off potential) for the protected structure. Now advance and portable, flexible, rugged, fully-programmable GPS synchronized current interrupter that is designed specifically for cathodic protection (CP) surveys. These interrupters helps operators to ensure corrosion mitigation effectiveness and meet regulatory requirements.

...more

CP Test Equipments

There are several test equipments available in the market, Himoya Corrosion Technolgy (P) Ltd. supplies all types of test equipment and accessories for CP system installation, survey and monitoring purpose. The test equipment used for obtaining cathodic protection data should be of an appropriate type. Instruments and related equipment should be maintained in good operating condition and checked periodically for accuracy.

...more

Cathodic Protection Anodes

For ICCP on ships, the anodes are usually constructed of a relatively inert material such as platinised titanium. A DC power supply is provided within the ship and the anodes mounted on the outside of the hull. The anode cables are introduced into the ship via a compression seal fitting and routed to the DC power source. The negative cable from the power supply is simply attached to the hull to complete the circuit. Ship ICCP anodes are flush-mounted, minimizing the effects of drag on the ship, and located a minimum 5 ft below the light load line in an area to avoid mechanical damage. The current density required for protection is a function of velocity and considered when selecting the current capacity and location of anode placement on the hull.

...more

Analog Voltage Panel Meter

Application : Control Panel Indication

Brand Name : Velleman

Voltage : 15v

Display Type : Manual

Color : white

...more

Polarization Cell

Be first to Rate

Rate ThisOpening Hours