Tinned Copper Wire Ropes

900 - 1,100 Per kgs

Indico manufactures Tin Coated Copper wire by going through 3 processes. In the first process, the wire is drawn in a specific size with Electrolyte (C.C. Rod) Copper and after doing the drawing process then it is send for the second process in which Annealing is done. In the third process, Tin Platting is being treated in this drawn Electrolyte Annealed Copper Wire. Generally it is done in two ways:- Hot Dip Process Indico copper wire manufacturers and suppliers melts the Tin in Electric Pot during the process and the Electrolytic Copper Wire is made dip through this melted Tin thereby resulting in Tin Coated Copper wire. Electroplating Process In this process, the wire is taken through a Chemical Tray and with the help of rectifier and Electric Current to DC Current is passed thereby resulting in electroplating. This process is done for House Wiring, Control Panel Cable & Other Electric & Electronical Wire as well as Cable too. Tin Coated Copper wire and cable is complex shaped. Tin coated copper wire is used as overhead power source for subways, light and heavy transit systems, electrically powered mine trains, buses, and industrial cranes. Tin coated copper wire likely also touches conduit, and other similar things etc. Tin Coated Copper Wire Everyone knows about the popularity and use of copper wire in the electrical and manufacturing industry. Wires created from copper are widely used in various industries due to its high electric conductivity and thermal conductivity. Indico draws the wires of various dimensions from copper and processes it using tin, thereby creating tin coated copper wires. Indico manufactures tin by two ways - copper wire hot dipping and electroplating. In the first method called hot-dipping, strands of copper are dipped into hot tin, which produces the required tin copper wire. In the second method, rectifier and electrical charge are used to tin the copper wires. Advantages of Tin Copper Wire Compared to non-tinned copper wire, the advantages of tin copper wire are longevity and its anti-corrosion properties. Tin copper wire lasts longer and produces amazing results even after years of deployment. On the other hand, non-tinned copper wires are not able to last as much longer. In addition to it, tinned copper wire has anti-corrosion properties which prove to be effective in marine usage as well as in those areas which have high moisture and humidity. Tin copper wire has more electrical conductivity as compared to non-tinned copper wire. Tin copper wires are extremely useful for industries such as electrical power industry, electrically powered trains, trams, trolleys, marine industry etc. Tin coated copper wires are also extensively used in industrial cranes and automobiles such as cars, buses and trucks. If you are looking for best quality tin coated copper wire, then you don’t need to worry at all. Indico manufactures and supplies high grade and stable tin coated copper wires, which are preferred and recommended by some of the top manufacturers and producers. For more information related to our company, you can check out our home page here. And for contacting us, you can send us a mail at indico.com.

Country of Origin : India

Type : Tin Coated Wire

Material : Tin

Application : Electric Conductor

Color : Silver

Insulation Material : Tin

Conductor Type : Stranded

Brand Name : INDICO

Conductor Material : Copper

...more

Flexible Circular Copper Earth

Indico manufactures exports and supplies Flexible Circular Copper Earth Bond made of numerous copper wires which are likewise now and again utilized for adaptable electrical associations between large components. The various littler wires involving the twist are a great deal more impervious to breaking under repeated motion and vibration than is a cable of larger wires. Flexible copper or flexible tinned copper braid are terminated with pressed ferrule connector at each end, and are suitable for bonding gates, doors, fences etc.

...more

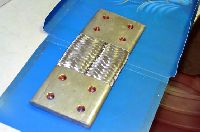

copper shunt .

Copper Flexible Shunts are specially designed in order to meet the requirements and specifications of the customers and are available in any pattern or size. The secondary conductor strips are of High Conductivity Copper. Terminal ends can either be deep riveted or solder dipped to allow a more positive current transfer area for improved efficiency.

Thickness : (0.035 To 0.3 Mm

...more

copper rope

Manufactures tin coated copper wire by going through 3 processes. In the first process, the wire is drawn in a specific size with electrolyte (c.c. Rod) copper and after doing the drawing process then it is send for the second process in which annealing is done. In the third process, tin platting is being treated in this drawn electrolyte annealed copper wire. Compared to non-tinned copper wire, the advantages of tin copper wire are longevity and its anti-corrosion properties. Tin copper wire lasts longer and produces amazing results even after years of deployment. On the other hand, non-tinned copper wires are not able to last as much longer.

...more

Copper Flexible Connectors

850 - 1,200 Per kgs

flat braided copper flexible connectors in transmitting current across conducting mediums which are subjected to different motions caused by thermal expansion, vibration or operational movement etc. These flexible connectors are widely used in electrical distribution, switchgear and automobile industries providing maximum conductivity and minimum millivolt drop maintaining excellent flexibility. Indico manufactures flexible connectors in the range of 1 mm² to 4000 mm² with range up to 4000 Amps and supplies it by using bare copper or tinned or silver plated braidedstranded wires with end terminals also either in Bare Copper or tinned or silver plated according to the requirements of the customer.

Type : Copper Flexible Connectors, Flexible Connector

Material : Copper

Grade : ETDC

Color : Brown, White

Feature : Easy To Connect

Warranty : 1year

Country of Origin : India

...more

copper braided wire

200 - 500 Per Kilogram

Copper Flexible Shunts are specially designed in order to meet the requirements and specifications of the customers and are available in any pattern or size. The secondary conductor strips are of High Conductivity Copper. Terminal ends can either be deep riveted or solder dipped to allow a more positive current transfer area for improved efficiency. Indico Copper Flexible Shunts manufacturer and suppliers make laminated Shunts by stacking several foils of Electrolytic Copper (0.035 to 0.3 mm thick) and then forging it by applying high current under high pressure. This is a special metal diffusion process whereby the metal itself melts and forms homogeneous bond thus giving a very negligible, almost nil millivolt drop across the connector, thereby reducing the temperature rise & increasing the current carrying capacity of the jumper. Indico uses no filler metal to join layers together during this process. They have a constant cross section over whole length. The current carrying capacity of solid bus bar and Copper laminated jumper manufactured by this process is same. Therefore these jumpers are a substitute of solid bus bar. It is also possible to drill, saw or mill the contact areas without any problem. These type of flexible connectors are used as flexible expansion joints in order to connect bus bars in Switchgear Industries, Power Plants, Caustic Soda & Chlorine Plant using Mercury Cell, Modular Cell, Membrane Cell, Diaphragm Cell, Hydrochloride Cell, Manganese Dioxide Cell and Cathodic Protection, Bus Ducts, Transformer, V.C.B., Resistance welding equipment, Electric Locomotives, Furnaces etc. to prevent damages by other parts of machines or switch gear. These kinds of jumpers have to realize movements inside machines and switchgear. Indico Copper Flexible Shunt manufacturer and suppliers manufacture and design these jumpers keeping in view, the user requirements and application. Indico also offer jumpers with contact area electro - tinned, Silver plated or Gold plated to give perfect contact.

...more

Copper Braided Flexible Connectors

900 - 1,250 Per kgs

Indico uses flat braided copper flexible connectors in transmitting current across conducting mediums which are subjected to different motions caused by thermal expansion, vibration or operational movement etc. These flexible connectors are widely used in electrical distribution, switchgear and automobile industries providing maximum conductivity and minimum millivolt drop maintaining excellent flexibility. Indico manufactures flexible connectors in the range of 1 mm² to 4000 mm² with range up to 4000 Amps and supplies it by using bare copper or tinned or silver plated braided/stranded wires with end terminals also either in Bare Copper or tinned or silver plated according to the requirements of the customer. Indico normally supplies flexible connectors in non-insulation design but if requested, they supply with insulation sleeves of heat shrink, silicone, PVC, fiberglass etc. Indico manufactures heavy duty Busbar flexible connectors using multilayered braids up-by-up or side-by-side in order to increase the current carrying capacity. This can be supplied from 250 Amps to 4000 Amps catering to Busduct, Switchgear and generator manufacturers.

Country of Origin : India

Type : Braided Flexible Connector

Color : Light Grey

...more

braided copper wires

900 - 1,400 Per kgs

Copper is one of the most useful metals ever used for electrical and chemical industries. Its chemical symbol is Cu and its atomic number 29. Indico is one of the leading braided copper wire manufacturer and supplier who uses copper for manufacturing and producing several commodities as it has extremely high electrical conductivity and thermal conductivity. Indico uses braided copper wires for high quality electrical products such as high and low volt electrical appliances, mining explosion devices, proof switches, automobile industry and marine industry. Indico makes braided copper wires by combining or braiding tin coated copper wires, silver coated copper wires and other such varieties, depending on the specific usage.

Country of Origin : India

Type : Braided Copper Wires

Application : Electric Conductor

Conductor Material : Copper

Brand Name : INDICO

...more

Braided Copper Wire

900 - 1,200 Per kgs

Copper is one of the most useful metals ever used for electrical and chemical industries. Its chemical symbol is Cu and its atomic number 29. Indico is one of the leading braided copper wire manufacturer and supplier who uses copper for manufacturing and producing several commodities as it has extremely high electrical conductivity and thermal conductivity. So, there is a constant increase in the production of copper wires over several years. Indico uses braided copper wires for high quality electrical products such as high and low volt electrical appliances, mining explosion devices, proof switches, automobile industry and marine industry. Indico makes braided copper wires by combining or braiding tin coated copper wires, silver coated copper wires and other such varieties, depending on the specific usage. Indico uses and implements braided copper wires where the focus and requirement is more on the flexibility and ease of usage. Normal copper wires and tin copper wires are primarily used in those appliances where straight and rigid use of wires is being executed. Braided copper wires are much more flexible. Examples: - headphone cables, speaker wires, jewellery creation and deep sea operations Braided copper wires are available in the form of wire assembly, shielding cable, soldering wire, control panel, switch gear box etc. The demand for braided connectors and jointers has also shot up in recent years because of high demand and usage of braided copper wires. Due to its flexible use and execution, more and more electrical appliances and devices are now opting for braided copper wire. So if you are looking for braided copper wire, then you don’t need to worry anymore. Your search for high quality braided copper wire finally ends with Indico. Having more than 30 years of experience in providing high quality and world class copper products, Indico is one of the leading braided copper wire manufacturer and supplier. For more information related to our products, you can always send us a mail directly at indico.com.

Application : Electric Conductor

Conductor Material : Copper

Conductor Type : Solid

Brand Name : INDICO

...more

Bare Copper Wire

825 - 1,000 Per Kilogram

50 Kilogram (MOQ)

Indico is manufacturer & exporter of Bare Copper Wire. Our product range also comprises of Submersible Winding Cables and Super Enameled Wires. Available in bare and tin, these Copper Wires can be used in various industrial applications. Indico manufactures and supplies a wide range of Bare Copper Wire, from advance wire drawing machine. We offer products to our customers in varied lengths and thickness. They are widely used in electrical industry. These bare wires and strips offer excellent corrosion resistance. We provide products at affordable rates and are technically advanced.

Country of Origin : India

Type : Bare Copper Wire

Application : Electric Conductor

Color : Browm

Conductor Material : Copper

Insulation Material : Enameled

Conductor Type : Stranded

Wire Gauge : 10-15mm, 15-20mm, 20-25mm

Grade : EC grade

Material : Copper

Corrosion Resistance : Yes

Surface Finishing : Polished

Speaciality : Perfect Finish

Wire Diameter : 1-3mm

Shape : Round

Grade : Ec

Packaging Type : Roll

Weight Per Kg : 50-100kg

Thickness : As per your request

Length : As per order

Tensile Strength : 100

Elongation : 100%

...moreBe first to Rate

Rate ThisOpening Hours