Digital Muffle Furnace

20,000 Per piece

1 Piece (MOQ)

Muffle Furnace

17,000 Per Piece

1 Piece (MOQ)

Best Deals from Industrial Furnace

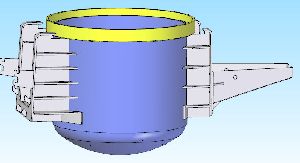

Submerged Arc Furnaces

Get Price Quote

We supply state-of-the-art submerged arc furnaces for the production of ferro alloys . We use ss bellow in the pressure ring.

Industrial Gas Burner

20,000 Per Piece

4114 SAIFEE GAS BURNERS ARE SEALED IN burners used for a wide variety of industrial applications. These burners are capable of efficient operation throughout a wide range of preheat air temperatures, and are equally stable on low temperature ovens as well as high temperature furnaces for reheating , forging, melting, drying etc. The sealed mounting stops unwanted air from the atmosphere from entering the burner, which helps maintain furnace pressure, controlled atmosphere and better oil/gas ratio for improved product quality. Saifee Gas burners are stable with 100% or more excess air. They can be turned down to much lower range but stability limits vary depending on burner size and furnace condition. For prolonged operations with low air pressure at temperatures above 850 dEGREE C, please specify an alloy burner nose. Burners are suitable for preheated combustion air upto 350 degree C.

Muffle Furnace

Get Price Quote

Tundish Preheater

Get Price Quote

Graphite Electrodes

Get Price Quote

20 Metric Ton (MOQ)

The company’s product are in four major series: The First series are RP, HP, SHP, and UHP graphite electrodes and anti-oxidant impregnated graphite electrodes in all specifications; The Second series is a new type of carbon material with excellent chemical resistance and excellent oxidation resistance and high-temperature stability of coarse graphite; The Third series is comprised of isotropic high density, high-strength, and high-purity graphite in all specifications; The fourth series includes non-standard graphite products used in graphite chemical equipment and mechanical machining as well as all kinds of irregular-shape carbon products and graphite processed products, etc.

Graphite Electrodes

Get Price Quote

Muffle Furnace

45,000 Per Piece

1 Piece (MOQ)

Industrial Gas Burner

48,500 Per Piece

Roller Hearth Tube Annealing Furnace

Get Price Quote

A wide assortment of Roller Hearth Tube Annealing Furnace is offered by us to our customers at market leading prices. This Roller Hearth Tube Annealing Furnace is highly durable in nature. Further, this Roller Hearth Tube Annealing Furnace is extensively used for the bright annealing or heat treatment of MS.Features: Maximum production Can bear maximum stress Durable

electrical furnace

Get Price Quote

Custom Built Heat Treatment Furnaces

Get Price Quote

Keeping in mind the exact demands of our valued clientele, we offer a wide range of Custom Built Heat Treatment Furnaces. These products are developed at advanced development unit using the best quality material and advanced technique. In order to meet the universal industry parameters, the entire range is stringently checked on diverse industry parameters. In addition, this product is available at low prices in the market. Features: Durable nature Topquality Low prices Applications: Heat Treatment Preheating Stress Relieving

Burner Block

Get Price Quote

We are offering burner block.

Ceramic coated furnace Carbon free hose

500 Per Meter

Carbon free hose offers an extremely long life through characteristics of abrasion and weather resistance. It is high flexibility together with adequate toughness to help passing the electrical cable assembly through the hose. Carbon free hose is specially designed and manufactured to take the abuse in your toughest working environments. You can always count on our carbon free hose for optimal performance at a competitive price. CERAMIC FIBRE GLASS COATED HEAT & FIRE RESISTANT CARBON FREE HOSE Non-Conductive (electrical) hose used as an outer protective covering for power cables in steel mills, glass works etc. To avoid damage to cable, leakage of current due to exposure to open flame, splashes of hot metal or radiation. Global Transmission Carbon Free Hose offers high flexibility together with adequate toughness to help passing the electrical cable assembly through the hose. Our Carbon Free Hose is specially designed and manufactured to take the abuse in your toughest working environments. You can always count on Global Carbon Free Hose for optimal performance

Hot Dip Galvanizing Plant

Get Price Quote

Since our inception, we are instrumental in offering premium quality Hot Dip Galvanizing Plant. The offered galvanizing plant is meticulously tested on various quality parameters and is widely demanded in various industries. Provided galvanizing plant is manufactured by utilizing optimum quality raw material and the latest technology at our manufacturing unit. In line with the international standard, we provide the entire range in various customized options and at affordable prices.

Graphite Electrodes

Get Price Quote

fluidized bed furnace

600,000 Per Piece

Salt Bath Furnace

Get Price Quote

rotary hearth furnace

Get Price Quote

Over the years of dedication, we have been serving our clients with a wide array of Rotary Hearth Furnace for our huge clientele base. This also includes heat treatment furnace in order to stand up to the demands of variegated customers. This furnace is capable of heating non-metallic elements like silicon carbide and super. Rotary Hearth Furnace is used for tempering, annealing, melting and brazing of alloys and iron. We use only best quality material in making our furnace highly functional, energy efficient and durable having a long operational life. We offer this at highly pocket- friendly prices among our competitors.Key Points :• It is used for tempering, annealing, melting and brazing of alloys and iron.• It stands high on efficiency, performance, durability and easy installation.• This furnace is tested on several quality parameters.• It is demanded in different industrial sectors.