Aluminium Worm Gearbox

4,500 Per Piece

5 Piece (MOQ)

Heavy Duty Crane Gearbox

Get Price Quote

1 Piece (MOQ)

Best Deals from Industrial Gearboxes

Worm Gearbox

Get Price Quote

Avail from us Worm Gearbox that is made from the finest grade stainless steel a. The latest technology Worm Gearbox is designed by the experts. Worm Gearbox complies with the national and international quality standards. The Worm Gearbox can be availed in different specifications from us. We are a well-known Worm Gearbox Supplier in Kolkata, West Bengal. Advantages Of Worm Gearbox Reduces rotational speed Allows high torque for transmission Can get a higher gear ratio as compared to the same range of spur gears Can operate under adverse conditions Can achieve large speed reductions Highlights Greaves Speed Reducers have Substantial construction Combined rigidity with strength The worm is Of high quality case-hardening steel Accurately generated Ground and super-finished The worm wheel comprises A phosphor bronze centrifugally cast rim of large section welded to a stiff centre, which is keyed and pressed to the shaft

cooling tower gearbox

25,000 - 250,000 Per Piece

1 Piece (MOQ)

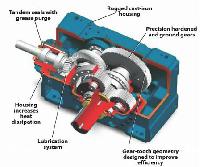

The gear reducer assembly is an essential component of a cooling tower that provides the necessary torque to drive the fan. Here are some specifications for a cooling tower gear reducer assembly: Capacity: The gear reducer assembly should be designed to handle the specified horsepower and torque requirements of the cooling tower. The capacity of the gear reducer should be specified in terms of the maximum horsepower and torque that it can handle. Gear Ratio: The gear ratio should be selected to provide the necessary speed reduction for the fan to operate at the specified RPM range. Materials of Construction: The gear reducer housing and internal components should be made of materials that provide high strength and resistance to wear and corrosion. Common materials include cast iron, steel, and aluminum. Lubrication System: The gear reducer should be equipped with a lubrication system to ensure proper lubrication of the gears and bearings. The lubrication system should be designed to provide sufficient oil flow and pressure to all critical components. Motor Mount: The gear reducer should be designed to mount to the motor and fan support structure. The motor mount should be adjustable to allow for proper alignment of the gear reducer and fan. Input and Output Shafts: The gear reducer should be designed with input and output shafts that are compatible with the motor and fan shafts, respectively. The shafts should be designed to handle the specified torque and speed requirements. Bearings: The gear reducer should be equipped with high-quality bearings that are designed to handle the specified load and speed requirements. The bearings should be sealed and lubricated for life. Seals: The gear reducer should be equipped with seals to prevent oil leakage and prevent contaminants from entering the gearbox. The seals should be designed to handle the specified operating conditions. Mounting: The gear reducer should be designed for easy installation and maintenance. It should be equipped with mounting flanges or feet that allow for easy attachment to the motor and fan support structure.

Worm Gear Boxes

Get Price Quote

1 Piece(s) (MOQ)

We are counted amongst the prominent Manufacturers and Suppliers of Worm Gear Boxes in West Bengal, India. We use the optimal quality components and progressive techniques for manufacturing them. We have enough capacity to deliver them in bulk quantities, within the stipulated time frame. The important features include high efficiency and load carrying capacity combined with a long life and reliable service. Range Power ranges up to 250 KW, Reduction Ratio ranges up to 4900: 1 Sizes Up to 300 mm centre distance Type under Driven / Over Driven / Vertical Units in Single & Double reduction Applications : Conveyor, Material Handling, Ball Mill, Thermal Power Plant Industries All Process Industry.

Worm Gearbox

2,000 - 40,000 Per Piece

1 Piece(s) (MOQ)

aerator gearbox

Get Price Quote

Range 112 to 250 with ratio of 25.6:1 to 42.5:1Applications Water Filteration Features » "GA" series parallel shaft vertical gear drives in triple reduction are intended to satisfy characteristic requirements and conditions encountered in Aerator application.» Sizes available from 112 to 250 with ratio range of 25.6 : 1 to 42.5 : 1 Aerator Gearbox Rating & Selection

aerator gearbox

5,500 Per unit

NU Gear Box

4,000 Per Piece

Worm Gear Box

Get Price Quote

1 Piece(s) (MOQ)

We are offering Worm Gear Box in the market. Our floor mountable Worm Gear Boxes are well known for their quality and reliability and their ability to meet the various needs of the industry. These Worm Gear Boxes have compact design, high thermal capacity, excellent strength and resistance to shock, good torque capacity, and smooth trouble-free operation. We offer these Worm Gear Boxes at competitive prices.

Reduction Gear Box

Get Price Quote

Body: Steel fabricated, stress relieved. Gear/Pinion: EN-24 steel, double helical, ultrasonic tested. Bearings: Antifriction spherical roller. Stage: 1 stage Shaft: EN-9, forged steel ultrasonic tested.

Worm Gear Box

Get Price Quote

Highly established company engaged in manufacturing, supplying and distributing outstanding Industrial Worm Gearbox. These Aluminium Worm Gearboxes are applied in varied industries and available at very economical prices. Our range of Motorised Worm Gearbox is made from superior aluminum, stainless steel and other high quality raw materials to reduce rotational speed and allow higher torque for transmission. With our worm gear boxes, the gears can achieve a higher gear ratio as compared to the same sized spur gears. Worm Speed Reducers are of substantial construction, combining rigidity with strength. The worm is of high quality case-hardening steel, accurately generated, ground and super-finished. The worm wheel comprises a phosphor bronze centrifugally cast rim of substantial section welded to a rigid centre, which is pressed and keyed to the shaft. We also customize designs as per the customers’ specification. Delivery of the consignments on time is crucial for us.

Pinion Stand

Get Price Quote

Pinion stand, Oil seals of very good quality are also provided at input & output ends of shafts to prevent leakages of oil, which is a normal phenomenon in gear boxes. For these reason UGI made Pinion stand have very good in India & abroad.

Worm Gear Box

5,000 Per Piece

Reduction Gear Boxes

5,800 Per unit

20 16 (MOQ)

High quality gear boxes at the reasonable price having better mobility.

Worm Reduction Gear Box

Get Price Quote

We offer worm reduction gear box. Pinions spur gear bevel gear helical gear we are engaged in offering a superior quality range of loose gear- worm wheel & worm spares. These worm gear are available under the brand name radicon, greaves, shanthi, elecon and sizes are 237,287,337,300,400,500,600,700,800,900,1000&1200, the range that we are supplying is known for its robust performance in all conditions.

Helical Gearbox

Get Price Quote

Gold die

gear reducers.

Get Price Quote

gear reducers.

Reducer

Get Price Quote

Reducer, Normal Butanol, Industrial Solvents, mixed solvent, mixed solvent

Reducer

Get Price Quote

Reducer, Tees, Pipe Fitting, Manhole Frame, Industrial Casting, Elbow

helical gear box

Get Price Quote

High Speed Gear Boxes

Get Price Quote

High Speed Gear Boxes, Chrome Steel Ball, bending Machines, Straight Gears

Reduction Gear Boxes

Get Price Quote

idler pulleys, Conveyor Pulleys, Roller Conveyors, Helical Gear Boxes

Pinion Stand

Get Price Quote

Pinion Stand, Cooling Bed, cooling equipment, Coil carrying Conveyors

bevel helical gear box

Get Price Quote

Worm Gear Box, Geared Motor, lift duty gear boxes, customised gear pinion set

extruder gearboxes

Get Price Quote

Worm Reduction Gear Box, spiral gear, SMSR Gearbox

Helical Gearbox

Get Price Quote

Gears, Helical Gears, Bevel gears, spur pinion gear

Reducer

Get Price Quote

Reducer, Elbow, Socket, screwed, weld neck, Stub end, Flanges

Worm Gearbox

Get Price Quote

Speed Reducers

Get Price Quote

Speed Reducers, Planetary Drives, Gear Motor, Helical Gear Motors