Walling & Ceiling

Wall & Ceiling panels are of 80mm thickness and have a composite structure of one side EGP sheet and the other side powder coated GI sheet with PUF filler in-between. The panels will be made from 0.8mm EGP sheet with a PUF insulation of density 40 in between. The PUF will have a thickness of 48.6mm and GI panel of 0.6mm on the upper side. The total ceiling will have a thickness of 50mm. the ceiling will also have a PU antibacterial paint. 2.1. Facing Material: EGP sheet will be finished with putty and a antibacterial antifungal coat to give a seamless coat. 2.2. Core Material: A core of CFC frees rigid Poly Urethane Foam with typical physical properties: 2.2.1. Density of 40kg/m3. 2.2.2. Coefficient of conductivity < 0.025W/mK 2.2.3. Tensile Strength > 0.1N/mm2. 2.2.4. Compressive Strength > 0.1N/mm2. 2.2.5. Tensile Modulus > 3N/mm2. 2.2.6. Compression Modulus > 3N/mm2. 2.2.7. Dimensional stability at 800C and at - 200C < 2%. 2.2.8. Water Absorption < 0.55kg/m3. 2.3. Panel Properties: 2.3.1. Standard panels with reaction to fire classified as Cs2d0 2.3.2. Panels with superior reaction to fire classified as Bs2d0

...more

Supply/ return air grills

Grills shall be of extruded aluminum construction having concealed screws for fixing. These shall be duly powder coated in the shade approved by TMH/ TSL. The grills shall have horizontal bars at 15/30 deg. inclination and flanges on top and bottom. The grills at the end shall have flange on the side as well as per the site requirement. The size of main extruded section for flanges shall be minimum 15 x 15 mm and the louvers shall be 15 mm deep having thickness of mm in the front and 2.8 mm at the rear.

...more

Pressure Relief Dampers

Pressure Relief Dampers will be provided in each OT to prevent cross contamination of air from clean and dirty areas. Suitably sized air pressure relief damper will be strategically placed, enabling differential room pressure to be maintained and ensure that when doors are opened between clean and dirty area. Counter-weight balancing system will be provided in the PRD to maintain positive pressure inside the operation room. Air pressure stabilizers will have unique capability of controlling differential pressure to close tolerance. The PRD will remain closed at pressure below the set pressure and should open fully at pressure only fractionally above the threshold pressure. The body will be epoxy powder coated as per standard BS colors. First class electrolyzed steel plate will be used for body and with high grade SS304 Stainless Steel for blades.

...more

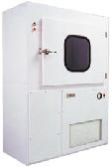

Pass Boxe

Pass Boxes are self-contained units installed at the entrance to Clean Room. They minimize the amount of particulate contamination entering the Clean Room by reducing operator "traffic". Equipment and materials are passed into the Clean Room via the pass box, which is equipped with a electro-magnetic interlock system that prevents both doors from being opened at the same time. Melius offer Stainless Steel construction for both Transfer and Trolley Pass Box, making them cost efficient for all manner of projects, from Chemical, Hospital to Clean Room environment. The specific design of the units offers a flush interior to the Hatch making it easy for clean-down procedures, with no protruding or recessed areas that promote Bacterial Growth, complete with Toughened Plate Glass Doors. Both types of pass thru Pass Box come complete with our unique electro-megnetic Interlock System to aid you in the reduction of Cross Contamination and Pressure Loss whilst passing product between your “Clean” and “Dirty” areas. Melius Pass Box is an inexpensive way to maintain the cleanliness of your Clean Room and is easy to install and adaptable to existing facilities. Rigid and rust-proof construction of electro-galvanized steel sheets Abrasion-resistant epoxy coated steel Easy to clean stainless steel base Acrylic panel door gives clear view of internal chamber Electro-magnetic Interlock system with reinforced construction reduces cross-contamination Easy to install and adaptable to existing facilities

...more

Operation Theatre Control Panel

The Surgeon Control Panel will meet Electrical Safety codes for High & Low voltage system, wired to the current IEE regulations. The room Surgeon’s Control Panel will be designed to cope with changing technology and equipment in operating environments. Control panel should be user friendly and ease of operating and maintaining purpose. The control panel will be of membrane type. The Control Panel shall be designed for front – access only. All internal wires shall be marked with plastic ferrule type cable markers, for ease of identification. The panel shall contain services as below : 6.1. Time Day Clock: Time Day Clock shall be digital type and clocks having high brightness characters. 6.2. Time Elapse Day Clock: Time Elapsed Day Clock shall be digital type and clocks having high brightness characters. 6.3. General Lighting System: General Lighting System shall incorporate all the necessary controls of the lighting system inside the theatre. 6.4. Medical Gas Alarm Panel: The medical gas alarm shall indicate High, Normal and Low gas pressure for each gas service present in the operating room and shall have an audible buzzer with mute facility. Pressure sensors shall be connected to MGPS for monitoring the pressures. 6.5. Hand Free Telephone set with memory card: A Hand Free Set Telephone system shall be incorporated in the panel with memory type card. 6.6. Temperature & Humidity Indicator: Temperature Indicator shall indicate the room temperature which should be connected to the local pressure switches of Air-Conditioning system. Indicator shall be digital type having high brightness characters, not less than 30mm in height. 6.7. OT Room Air Pressure Indicator

...more

Medical Compressed Air & Gas Testing

The NFPA 99 Health Care Facilities, 2005 specification provides requirements for medical gas systems in health care facilities. Melius provides air and gas analyses in support of these guidelines. Medical Gas Testing Requirements Include: 1. Piping Particulate 2. Medical Gas Purity 3. Piping Purity (Air, O2, N2O, N2) 4. Medical Gas Concentration Test (O2, N2O, N2) All of our systems provide fast and accurate results while still meeting the specifications of air purity standards. Standards such as NABH, CGA Grade D and E, DIN 3188, NFPA 1500, CSAZ180.1-M85 and EN12021 can be fulfilled.

...more

Laminar Flow Workstations

Laminar Flow Workstations provide a high degree of localized control for critical processes. The Laminar Flow Workstations operate by drawing ambient air, under negative pressure, into the top of the unit. This air first passes through a pre-filter which traps the larger dust and dirt particles. The blower then directs this pre-filtered air, now under positive pressure, through the 99.99% efficient HEPA filter engulfing the entire work area with sterile, unidirectional ultra-clean air. This air travels at a velocity calculated to prevent the intrusion of unfiltered room air into the work area. It also washes away particles that may be generated by manipulations within the Workstations.Sterile, particle-free air is essential in such diverse processing areas as electronic assembly, sterile packaging and hospital pharmacy I.V. preparation. These processes and products require isolation from the contaminant typically found in ambient air. This clean environment can be best achieved and maintained by utilizing filtered laminar flow air in an appropriate workstation.

...more

Glove Box

A clean, controlled, positive-pressure environment is essential to your work, whether you are handling chemicals or pharmaceutical/biological materials, welding fibre optic components to create a hermetic seal, or processing lithium batteries or LEDs. Glove Boxes from Melius provide an ideal solution to creating the atmosphere and environment you need to safely and efficiently perform your work. Glove Boxes from Melius provide Safe, Reliable Solutions for : · Chemical Research and Manufacturing · Biological Processing and Safety · Materials Research and Manufacturing · Pharmaceutical Research and Manufacturing · Titanium Welding and Heat Treating We don't just sell systems - we design, manufacture, and even install them expressly for you. This means we know our products and what they can do for you. It also means we can monitor quality control every step of the way so you will be sure your Glove Box works right every time. Features and Specifications · Available in three widths, 1200mm (47"), 1800mm (71"), and 2400mm (94"). · A dual microprocessor control specifically designed for gloveboxes. Easy to use with all key information available on one screen. (A touch screen is also available, which can be PLC controlled.) · A 0-60 cfm stainless steel blower controls circulation. · The glove box is designed to maintain an atmosphere less than 1 ppm O2 and 1 ppm H2O. This is attained by a gas purification system that is easily accessible, and has automatic valves. · A large antechamber is installed with auto control optional. A rapid transfer chamber is also available. · Vacuum pump. · 0.3 micron inlet and outlet filters. · Box shelving standard or customized.

...more

Fusible link Type Fire Dampers

9.1. All supply and return air ducts at AHU room crossings and at all floor crossings shall be provided with approved make fire dampers of at least 90 minutes fire rating. 9.2. Fire damper blades and outer frame shall be formed of 1.6 MM galvanised sheet steel. The damper blade shall be pivoted on both ends using chrome plated spindles in self lubricated bronze bushes. Stop seals will be provided on top and bottom of the damper housing made of 16 G galvanised sheet steel. For preventing smoke leakage side seals will be provided. In normal position damper blade shall be held in open position with the help of a spring held in position by fusible links of approved rating thereby providing maximum air passage without creating any noise of chatter. 9.3. The fire damper shall close due to temp rise in SA. Ducts thru the fusible links factory set at 165 Deg. F. micro switches with bakelite base will be provided to stop fan motor and give open and close signal at remote panel in case of fire. 9.4. The fire dampers shall be mounted in fire rated wall with s duct sleeve 600 MM long. The sleeve shall be factory fitted on fire damper. The joints at sleeve end shall be slip on type. Minimum thickness of GI sheets shall be 18G.

...more

Fan Filter Unit

Fan Filter Unit (FFU) is air cleaning equipment to supply purified air to the clean room for manufacturing semiconductor , liquid crystal, etc. The installation space is the system ceiling grid. For a large clean room, the number of required FFU is from several hundreds to several thousands. Concept of FFU Development1. To reduce running cost by saving energy2. To reduce construction cost and term by thin, light and compact structure3. To reduce initial cost by total design of clean room including noise spec.etc Advantage of clean room with FFU : The construction period can be shortened The degree of cleanness from class 1 to class 1000 can be set and the degree of cleanness can be set at each area Because the back in the ceiling is a low-pressure, the potential of the leakage is low Bay method or through the wall method is possible by the arrangement of layout of FFU The velocity of the air flow can be set at each area Flexible increase or change of the clean room is possible by the arrangement of FFU

...more

Dispensing Booth

The Dispensing Booth is a containment solution for the weighing, the handling and the dosing of chemical and pharmaceutical active products with the operator outside the LAF (laminar airflow) area. This Dispensing Booth is a vertical laminar flow of Class M 3.5 (Fed. Std. 209 E) air, with a vertical return grid on the frontal side supplied with absolute filter on recovery and recirculation air. The cabinet is designed with part of the air re-circulate and quote of air exhausted outside, after absolute filtration. The operator and product protection by cross contamination between environmental / product and vice versa will be obtained with a physical containment into handling area powder, with a slight negative pressure inside the cabinet and a airflow barrier at level of front working aperture. The air front barrier is designed to permit an aspiration equal to 30% of the total air with a minimum air frontal velocity of 0.40 m/s and recirculation of the remaining 70% of the air on the working area in laminar air flow condition equal to a velocity of 0.45 m/s +/-20%. The sterility – cleanness of working area is guaranteed by a filtration of the air by absolute HEPA filter H14 and velocity of 0.45 m/s +/-20%. As far as product protection from the operator is concerned, it also relies on the down-flow of the HEPA filtered air, as well as on the appropriate personal protection devices like individual garments including mask, headgear, white coat, gloves and compliance with all the sanitary and safety regulations recommended in the Operating Manual of the Dispensing Booth and in the user safety procedures (like CGMP).

...more

Conventional HEPA Filters

The Caracas of the plenum will be made of extruded aluminum sections in such a manner that the air is passed only through the filters only. Plenum unit for laminar flow diffuser will be made of thick aluminum sheet. The complete unit will have factory prepared fine sealing system. The plenum will be supplied at site duly sealed in factory made packing. The Laminar flow system will have anodized aluminum perforated diffuser grill. The laminar flow system will have such design that it provides cleanliness of class 1000.

...more

Conductive / Dissipative Flooring

2mm Conductive flooring with Carbon backing having weight of 3kg/m². the product will be Poly Urethane reinforced (PU-Shield), scratch resistant, fire resistant, chemical resistant, slip resistant, antifungal, antibacterial growth, with a dimensional stability of &li; 0.4%, static electrical charges &li; 2KV, impact sound reduction (approx). The floor should have an electrical resistance of 2.5 x 10 to 10 6 Ohms.

...more

Biological Safety Cabinet

The class I safety cabinet provides a wide performance envelope for the user from aerosol hazards and other particulate within the cabinets work area. All extract air is exhausted through HEPA (high efficient particulate air) filtration generally to atmosphere although recirculation models are also available through Safety Cabinet Solutions. Inflow air velocity should be between 0.7 and 1.0 m/sec and by their design nature are less susceptible to poor working techniques of the user or less than ideal room air conditions. The class II microbiological safety cabinet (class II MSC), unlike the class I microbiological safety cabinet (MSC) provides protection to both the user & the material within the cabinet's working environment. Protection for the user is provided by means of an inflow air curtain whilst the sample material in the cabinet is protected from the dirty laboratory environment by a constant stream of HEPA filtered air (airflow velocities inflow > 0.4 m/s & down flow between 0.25 and 0.5 m/sec). All Class II cabinets are designed for work involving microorganisms assigned to biosafety levels 1,2 and 3. These cabinets provide a suitable environment for cell culture propagation and may also be used for the formulation of nonvolatile antineoplastic or chemotherapeutic drugs.The class III microbiological safety cabinet (often wrongly referred to as a glove box) is a highly specialized product designed for the most hazardous work typically carried out in a containment level 3 or 4 facility. Like the class II safety cabinet this class of cabinet provides protection for both the user and product albeit both to a much higher degree. Class III cabinet protection to the user is provided by means of barrier protection with the user working through gloves or gauntlets and protection to the material within the cabinet by means of the air being HEPA filtered as such, unlike the class II MSC open fronted cabinet the class II is almost immune to outside air influences. The inside of the cabinet operates at a negative pressure to the surrounding environment with the exhaust air being vented through a HEPA filter to atmosphere.

...more

air shower pass box

Equipment and materials are passed through the air shower pass box while particulate contamination is washed off with high velocity HEPA-filtered air jets. Contaminated air is then taken in through the base of the unit, filtered, and recirculated into the chamber. To facilitate the proper removal of particulate contamination, Melius Air Shower Pass Boxes are built-to-order with a standard shower duration of at least 12 seconds. · Rigid and rust-proof construction of electro-galvanized steel sheets · Abrasion-resistant oven-baked powder-coated finish · Antimicrobial coated structure eliminates 99.9% of bacterial presence on external surfaces within 24 hours. · Permanently lubricated direct drive centrifugal blower · Equipped with a high quality Minipleat HEPA filter (filtration efficiency of more than 99.99% at 0.3 microns) · Ultra-quiet noise level of less than 70 dBA during operation · Stainless steel nozzles provide high velocity air jets for an efficient scrubbing action to remove particulates contamination · Acrylic panel door allows a clear view of the internal chamber · Easy to clean stainless steel perforated base · Easy to install and adaptable to existing facilities

...more

air handling systems

Air handling system, OT interior & OT equipments. There are several options available in each part from where options are selected as per need, choice & budget. OT being most critical area in a hospital complex, it is necessary to control OT air in respect of temperature, humidity & particulate matter content of air, micro-organisms, i.e. bacteria, viruses, fungi etc. Air handling systems process air through various stages. Air is cooled, moisture is removed, air is filtered to remove dust particles, bacteria, viruses; some air handling systems additionally remove gases, odors and other volatile organic compounds. Laminar Air Flow is non-turbulent air flowing in parallel lanes vertically. LAF is filtered air coming over operative area from diffuser plenum above it. Plenum is fitted with HEPA (High Efficiency Particulate Air) filters of 0.3micron at 99.99% efficiency. Many times it is seen that plenum also works as light source above operative area; it has CFL/LED lights inside which provide clear shadow less light over operative area. It is necessary to maintain particular air velocity in LAF so that filtered air coming over operative area carries bacterial load away from it. According to international standards it should be between 90-120 FPM (feet per minute). NABH (National Accreditation Board for Hospitals & Healthcare) also recommends the same. Highly clean air of LAF falls in CLASS 100/ISO 5 category. When this air moves further in OT after leaving LAF area it mixes with less clean air of the room along with heat, moisture, bacterial load carried from operative area. It gradually looses it's clean state and while it reaches the last point in OT from where it is sent back to Air Handling Unit. Air in peripheral area of LAF normally falls in CLASS 10,000 - 100,000 categories depending on Air Handling Unit & OT size. LAF can be made in various sizes. Apart from these standard sizes any other customized size can also be made. Air Handling Unit has 3 filtration stages in total. First is 10 micron pre-filter, second 5micron fine-filter and third 0.3 micron HEPA filter. Out of three, first two are fitted in Air Handling Unit and last i.e. HEPA is fitted in plenum above operative area. Fresh air is added to this within AHU. Positive pressure is created to restrict outside air entering OT though door etc. Necessary cascade pressure relief dampers are provided in wall to relieve excess pressure in hermetically sealed areas. Air conditioning is done within Air Handling Unit to provide required cooling; no extra a/c is required in OT apart from this. HEPA plenum can be made in GI powder coat, Aluminum powder coat, SS304. Specification of AHUs : 1.1. Type of Casing : Double Skin Polyurethane Foamed, Floor Mounted 1.2. Casing Details : Inner casing - 1.0 mm Aluminum / SS316 , Outer Skin : GI - 1.0 mm Power Coated 1.3. PUF Insulation Thickness : For outdoor Application 45mm Thick , 40 Kg/ m3 Density & for Indoor Application 25 mmThick,38 Kg/m3 Density. 1.4. Cooling Coil : 6 rows deep Copper Tube, Fins - Al. 12-13 FPI, Copper Tube Thickness shall be Minimum 0.5 mm. 1.5. Coil Casing-(Top/Side/Bottom ) : SS316 1.6. Drain Pan Material : SS 316 1.7. Drain Pan Insulation : 19mm Thick, Closed cell Nitrile Rubber,50 Kg/m3 Density. 1.8. Filter Frame where the Filter will be mounted : shall be Aluminum Heavy Gauge. 1.9. Pre-Filter & Microvee Filter Frame Material : Aluminum. 1.10. Fan : DIDW backward curved Centrifugal fan. 90 mm of water static pressure. Make : CG / Nikotra / Kruger. 1.11. Motor : Suitable for 415 + 10% volts, 50 cycle, 3 phase AC supply. 1.12. Fan & Motor Mounting : Heavy gauge Aluminum. 1.13. AHU Mouth Damper & Flange : Aluminum. 1.14. Provision will be made so that AHU cooling unit can be bypassed when required. For outdoor Application Thermal Break profile is recommended.

...more

Air Curtain

air curtains are quiet, attractive, and affordable and can help you create a more comfortable front-end entrance. Non re-circulating air curtains are used on a variety of doorways where additional climate control is desired, Melius's units are attractive and easy to install above any existing entrance where a minimum of 14" of headroom is available. The unit is for single or double doors, both automatic and manual. Air curtains are designed to provide an invisible barrier between your sterile processing area and un-controlled environment. Prevents entry of dust, smoke, flies etc.

...more

Static Systems

Be first to Rate

Rate This