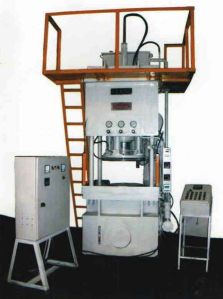

Single Station Quench Press (3-Ram 40T)

Get Price Quote

SIMPLETEC hydraulically operated 3-Ram 40T Quench Press, designed for gears, bearing races, etc., is a single station hydraulic quench press. The outer ring pressing force is 15T, the inner ring pressing force is also 15T and the pressing (or expansion) force of the plug is 10T. All the pressing forces can be independently set. Quench pressure, time and oil flow can be set precisely as required and measured. Pressing forces of the inner ring, outer ring and the plug can be seen on the HMI provided in the electric panel of the machine. Except loading of components, all other operations are automatic. Pick & Place Manipulators for automatic loading and un-loading of components, Secondary Quench System and quench oil Chilling Unit can also be provided. (Photograph shown is without the quench oil guards).

Sealed Quenching Furnace machine

Get Price Quote

Indomen sealed quench furnace is a highly productive and efficient integral-quench furnace available in either gas-fired or electric models. It is the centerpiece of a complete heattreating system. The furnaces feature obstruction-free work chambers, large capacity re-circulation fans, and strategically located heated sources to ensure rapid heat transfer, low energy use, and excellent temperature and carbon uniformity. A size and in-out configuration is available to fit your needs.Indomen(sealed) integral quench furnaceModels:sqf-80,120,320,600,800,1000Bringing you over 14 years of innovative furnace designFeatures/benefits Fully automatic movement of the load within the furnace,including quench. Programmable logic controller eliminates sequencing circuit relay maintenance. Temperature and atmosphere carbon potential are bothautomatically controlled. A two-pen strip chart records both furnace temperature and percent carbon. Preheat oil quench with immersion heaters, temperature and excess temperature controllers Oil level sight gauge and level alarm. Air-to-oil quench cooling heat exchanger. Flowmeters for endothermic gas, natural gas additions,ammonia gas additions, and air for carbon burnout.Emergency nitrogen gas purge circuit activates on power failure or loss of atmosphere. Scr power control for electrically heated models.Recuperative vertical radiant tubes for gas-fired models.Applications Annealing Carbonitriding Carburizing Tool steel hardening up to 1850°f Normalizing Temperature range:1850°f (980°c)Options Upper atmosphere cooling: oil-cooled double walled chamber above the quench, cools the workload under protective atmosphere.Atmosphere cool/oil quench selector switch. Upper cooling is available with or without a recirculating fan to accelerate load cool down. Hot oil quench with additional immersion heaters and insulation lagged to the quench tank shell. Variable speed quench agitation. Enhanced furnace control components. Complete system automation to suit your unique requirements.

Best Deals from Quenching Machine

Quench Press

1,000,000 Per Unit