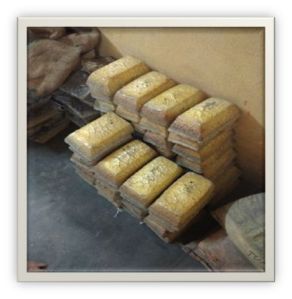

Zinc Ingot

235 - 310 Per Kilogram

1000.00 Kilogram (MOQ)

Zinc Ingot is a white or grey colour pure Zinc Metal which is cast into a block and bar that is suitable for furthur processing of metal. The Zinc Ingot is produced using solid state crystallization and ultra high purification processes including sublimation. It has various properties such as high malleability, low maintainence, durable finish standard, free from impurities & high strength. The Zinc Ingots formed have hardwearing material strength and offers resistance to rust. It finds application in the hot dip galvanizing steel, electrolytic galvanizing, photoengraving plates, zinc oxide, zinc plates, sacrificial anodes & Zinc ball. In our Foundry, we are stocking Zinc Ingots for reselling purpose as wel as for our ouwn Foundry Consumption. We are offerring Good Prices for the Items on Demand. Zinc Ingots present with us are of 99.995 Percent Pure.

Packaging Type : They Are Packed In Jute Cloth & Loaded Onto Vehicle For Transportation.

Size : 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, BS

Type : Zinc Ingot

Material : Zinc

Shape : Rectengular, Square, The Shape Of Ingots & Slabs.

Weight : 1-100kg

Grade : ASTM, BS

Color : Grey, White, Bluish Silver Colour

Purity : Zn: 99.995%

Condition : New

Surface Finishing : In The Form Of Pure Zinc Ingots

Country of Origin : India

Application : Industrial Sectors Like Chemical, Rubber, Automobile, Battery To Furniture.

Dimension : As Per Hindustan Zinc Size Of Ingots

Chemical Composition : Zinc Content: 99, 995 Percent

...more

Zinc Alloys Rods

350 - 475 Per Kilogram

100 Kilogram (MOQ)

Material : Zamak Ingot

Color : Light White

Zinc Alloys Ingot

270 - 450 Per Kilogram

300.00 Kilogram (MOQ)

Zinc is a common additive to base metals to create Zinc Alloys. These alloys are formed and worked into various applications depending on the types of metals that are alloyed together. Zinc is usually considered a weak base metal. It is very brittle due to which it is used in Coating & Galvanizing applications where other metals will take on Load Bearing Duties. When Zinc is alloyed with other stronger metals, it can attain a higher impact strength. The alloyed metal also provides electrochemical properties and is extremely malleable in extremely malleable in lower working conditions between 2000 F - 3000 F. Due to these properties, the metal is used in more complex fabrication and galvanizing processes. Zinc also has good corrosion resistance properties. Zinc Alloys have varied uses based on industries. In addition, the purity level of zinc also decides which application the Zinc would be used in. Zinc Alloys are used in various applications like Automotive Industries where they are used for coatings for galvanized steel. Galvanizing Steel Parts and components helps in preventing corrosion. In medical field, zinc alloys are used since they are considered environmentally safe. In Buildings & Constructions, Zinc alloys are used in a wide range of applications as products. They are used as solder, household fittings and as coating on roofing & cladding products. Zinc Alloys find use in marine applications where they are used as sacrificial anodes for marine vessels and other applications that are exposed to saltwater environments. The Following table lists the Zinc Alloys Manufactured by us: - General Designation ASTM Designation Percentage Composition Al Cu Mg Fe Maximum Pb Maximum Cd Maximum Sn Maximum Ni Zn Zamak 2 AC43A 3.5-4.3 2.5-3.0 0.02-0.05 0.100 0.005 0.004 0.003 --------------- Remainder Zamak 3 AG40A 3.5-4.3 0.25 Max 0.02-0.05 0.100 0.005 0.004 0.003 Remainder Zamak 5 AC41A 3.5-4.3 0.75-1.25 0.03-0.08 0.100 0.005 0.004 0.003 Remainder Zamak 7 AG40B 3.5-4.3 0.25 Max 0.005-0.02 0.075 0.003 0.002 0.001 0.005-0.020 Remainder ZA - 8 8.0-8.8 0.8-1.3 0.015-0.030 0.075 0.006 0.006 0.003 Remainder ACuZinc5 2.5-3.3 5.0-6.0 0.025-0.05 0.075 0.005 0.004 0.003 Remainder ZA - 12 10.8-11.5 0.5-1.2 0.020-0.030 0.05 0.005 0.005 0.002 Remainder ZA - 27 25.5-28.0 2.0-2.5 0.012-0.020 0.07 0.005 0.005 0.002 Remainder

Size : 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, ASTM, BS, DIN

Type : Zinc Alloy Ingot

Material : Zinc Alloy

Shape : Rectengular, Square

Application : Construction, Household Repair, Marine Hardwares

Weight : 1-100kg, Weighs Around 7 Kg - 8 Kg

Grade : ASTM, BS, DIN

Color : Different Alloys Have Different Colour Codes

Purity : Lead & Nickel

Condition : New

Surface Finishing : Non Polished, Surface Finish Of As Cast Zinc Alloys Ingots

Country of Origin : India

Brand Name : RJMI

Dimension : As Per Customer's Requirements

Chemical Composition : As Per Various Alloys Of Zinc

...more

White Metal Ingots

3,250 - 5,150 Per Kilogram

300.00 Kilogram (MOQ)

White Metals/ Antifriction Bearing Alloys Ingots & Castings are cast as per IS:25-1979 Reaffirmed 2003 Specification. White Metals are cast as per 10 Grades of Anti Friction Bearing Alloys. The ingots manufactured are homogeneous and free from nonmetallic inclusions and have a clean appearance and fine grain structure. White Metal alloys are used for lining of petrol & diesel engine bearing crossheads in steam engine and other bearings used at high speeds. They are used for repair jobs in mills and marine installations, for underwater applications as a bearing alloy and gland packings, for lining of bearings required for medium speeds such as centrifugal pumps, circular saws, converters, dynamos and electrical motors, for low-speed bearings such as pulp crushers, concrete mixers and rope conveyors. They are again used for heavy duty bearings, rolling mill bearing in sugar, rubber, paper, steel industries, bearings for diesel engines, crossheads in steel engines, turbines etc. They are used for mill shaftings, railway carriage & wagon bearings and as a thin line overlay on steel strips where the white metal lining material is 0.076mm thick. The 10 grades of Anti Friction bearing alloys with chemical compositions are tabulated below: - Grade Alloying Elements, Percent Impurities, Percent, Max Total of Indicated Impurities, Percent, Max Sn Sb Pb Cu Ni Cd As Zn Fe As Al Bi Zn Cd 90 90 Min 6.5-7.5 0.3 Max 2.5-3.5 ----- ---- --- ------ 0.08 0.10 0.005 0.05 0.008 0.05 0.15 84 84 Min 9.0-11.0 0.3 Max 5.0-6.0 ----- ---- --- ------ 0.08 0.10 0.005 0.05 0.008 0.10 0.17 75 74.0-76.0 10.0-12.0 Remainder 2.75-3.25 ----- ---- --- ------ 0.08 0.10 0.005 0.05 0.008 0.10 0.17 69 68.0-70.0 0.2 Max 0.3 Max 1.0-1.4 ----- ---- --- 29.0-31.0 0.10 0.15 0.005 0.08 ------- 0.10 0.22 60 59.0-61.0 11.0-12.0 Remainder 2.5-3.5 ----- ---- --- ------ 0.10 0.15 0.005 0.08 0.01 0.10 0.22 20 19.0-21.0 14.0-16.0 Remainder 1.25-1.75 ----- ---- --- ------ 0.10 0.20 0.005 0.10 0.01 0.10 0.26 10 9.0-11.0 13.0-15.0 Remainder 0.50-1.0 ----- ---- --- ------ 0.10 0.20 0.005 0.10 0.01 0.10 0.28 6 5.0-7.0 14.0-16.0 Remainder 0.80-1.20 0.80-1.50 0.70-1.50 0.30-0.80 ------- 0.10 ------ 0.05 0.10 0.05 ------ 0.15 5 4.5-5.5 14.0-16.0 Remainder 0.30-0.70 ------- ------- ------- ------- 0.10 0.25 0.005 0.10 0.01 0.10 0.28 1 0.75-1.25 15.0-16.0 Remainder 0.5 Max ------- ------- 0.8-1.1 ------- 0.10 ------ 0.005 0.10 0.01 0.10 0.28

Brand Name : RJMI

Material : Metal

Country of Origin : India

...more

Tin Solder Stick

1,700 - 2,100 Per Kilogram

100 Kilogram (MOQ)

Material : Solder Soft

Brand Name : RJMI

Tin Ingot

2,560 - 4,500 Per Kilogram

1000.00 Kilogram (MOQ)

Besides our Own Foundry Consumption, we are Stockists & Resellers of Tin Ingots which come in Malaysian, Indonesian & Chinese Brands. Tin Ingots available with us are 99.99 Percent Pure. We do offer our best prices which are acceptable by many buyers in our State & Outside. However, depending on end user, we are customizing our products to 99.85 Percent Purity & 99.75 Percent Purity which are available with us as per demand.

Material : Pure Tin

Shape : Rectengular

Color : Silver, White

Type : Tin Ingots

...more

Tin Bronze Ingots & Castings

785 - 1,085 Per Kilogram

300.00 Kilogram (MOQ)

In our Firm, we are casting Tin Bronze Ingots & Castings as per IS:306-1983 Or Latest Specification. We are casting Ingots weighing between 7Kg - 10Kg & 12Kg - 15Kg which are used for Remelting & Alloying For Producing Finished Products in Large Scale Industries. The Castings Prepared by us range from weights of 0.300 Kg to 150 Kg in weight & are required in various applications. Castings are supplied with reasonable tolerances due to which they are machined again at the End User's Site. It is ensured that castings are clean and free from harmful defects such as blow holes and gas cavities. Tin Bronze Castings are utilized in movable bridge components, turntables for bridges and other structures for fixed and expansion bearings with slow and intermittent movement with heavy Loads. They are found in Gear, High Strength Bushing. This alloy is used in pump impellers, piston rings, steam fittings and valve bodies. Constituents Percentage Composition Ingots Castings Tin 9.5-10.5 9.5-10.5 Zinc 1.75-3.25 1.5-3.0 Lead 1.5 Max 1.5 Max Nickel 1.0 Max 1.0 Max Iron 0.15 Max 0.15 Max Aluminium 0.01 Max 0.01 Max Silicon 0.02 Max 0.02 Max Bismuth 0.03 Max 0.03 Max Total Impurities, Max (Includes Iron, aluminium, arsenic, antimony, silicon, bismuth) 0.50 Max 0.50 Max Copper Remainder Remainder

Country of Origin : India

Type : Tini Bronze Alloys Ingots & Castings

Color : Colour Ranges From Orange Yellow To Yellow Golden Colour

...more

White Metal Alloys Ingot

490 - 3,100 Per Kilogram

300.00 Kilogram (MOQ)

White Metal Alloys have low friction and wearing properties making them ideal for use in machinery were smooth and reliable operation is critical. They have strong inertness and extreme hardness applied in service severe conditions excellent strength and high operating temperatures. White Metals are a family of alloys that contain Tin, Antimony and Copper along with other elements like Lead & Arsenic. They are commonly used in large machinery applications such as turbines and generators. Babbitt Metal contains Tin, Antimony & Copper with smaller amounts of elements such as Lead & Zinc. Babbitt Metal is commonly used in high speed & heavy load bearing applications such as automotive engines and heavy machinery. The special grades of white metals are tabulated for their properties are as follows: - Product Name Product Description ASTM B23 Grade 1 Babbitt Alloy Chemical Composition: Tin: 90-92%, Lead: .35% max, Antimony: 4.0-5.0%, Copper: 4.0-5.0% Tin Based Babbitt that is slightly softer than Grade 2 Babbitt. For applications requiring high speed but less pressure. Babbitt Alloy #1 Chemical Composition: Tin: 90-92%, Lead: .0004% max, Antimony: 4.0-5.0%, Copper: 4.0-5.0% A Special High Purity Lead Free Tin Based babbitt that can be used for bearings found in commercial ovens, material pumps and transport equipment used for handling food grade materials. ASTM B23 Grade 2 (GEN) Genuine Babbitt Chemical Composition: Tin: 88-90%, Lead: .35% max, Antimony: 4.7-8.0%, Copper: 3.0-4.0%. It is used for high speed and low-pressure applications. Ideal for repairing older airplane, automobile, boat, tin based Babbitt and not Lead as a Babbitt and steel liner. They are good for old connecting rods, crank pins, compressors, cutters, centrifugal pumps, dynamos, bus and diesel train engines and railway car axle bearings that used a mill gearing, elevators, arbors, trimmers, steam cylinders, steam pumps, band saws, swing saws, and tube mills that turn at high speed. ASTM B23 Grade 3 Babbitt Alloy Chemical Composition: Tin: 83-85%, Lead: .35% max, Antimony: 7.5-8.5%, Copper: 7.5-8.5%. Heavy Duty Tin Based Babbitt for High Speed, High Loads and High Shock applications. They are also used as general-purpose high-speed Babbitt for thin bearings of light running machinery with light to medium pressures such as compressors, electric motors, pumps and stationary engine parts. Engine Babbitt Alloy Chemical Composition: Tin: 85.5-87.5%, Lead: .25% max, Antimony: 6.5-7.5%, Copper: 6.5-7.6%. This Babbitt Alloy is used for Ford Engines. ASTM B23 Grade 4 Babbitt Alloy Chemical Composition: Tin: 80.5-82.5%, Lead: .25% max, Antimony: 12.0-14.0%, Copper: 5.0-6.0% Originally designed as a Thrust Washer Babbitt, this hardware grade Babbitt alloy is used for various non-critical low speed applications. It is customized to prepare it for specific applications requiring Grade # 4 Babbitt. ASTM B23 Grade 5 Babbitt Alloy Chemical Composition: Tin: 61.0-63.0%, Lead: 24.0-26.0%, Antimony: 9.5-10.5%, Copper: 2.5-3.5% Customized for specific applications requiring Grade # 5 Babbitt. ASTM B23 Grade 6 Babbitt Alloy Chemical Composition: Tin: 35-37%, Lead: 50-52%, Antimony: Copper: 0.5-1.5%. Customized for specific applications requiring Grade 6 Babbitt. ASTM B23 Grade 10 Babbitt Alloy Chemical Composition: Tin: 9.3-10.7%%, Lead: 78.0-83.0%, Antimony: 14.5-17.5%, Copper: .6% Customized for specific applications requiring Grade 10 Babbitt. ASTM B23 Grade 13 Babbitt Alloy Chemical Composition: Tin: 5.5-6.5%, Lead: 83-85%, Antimony: 9.5-10.5%, Copper: .5% Lead Based Babbitts Designed for Mill Anchor for Knife Blades. Babbitt Alloy Special Grade Chemical Composition: Sn: Balance, Sb: 7% - 8%, Cu: 3% - 4%, Ni: 0.2% - 0.3%, Cd: 1% - 1.5%.

Material : Metal

Country of Origin : India

Brand Name : RJMI

Diameter : Material In The Form Of Ingots

Shape : Shape Of Ingots

Melting Point : 232 Degree Centigrade

Type : White Metal Alloys

Length : 0-5Ft

Application : Industrial Use

Color : Shiny-white, White

Feature : Perfect Shape In The Form Of Ingots

Pattern : Cast As Ingots & Slabs

Finishing : Ingots Have Shiny Surfaces With Bright Shapes

Feature : Shiny Look

Dimension : As Per Weight & Size Of Ingots Required

Jewelry Type : Both Lead Based & Tin Based Alloys Are Used In Jewellery

Chemical Composition : As Per Specification For Special Grade White Metals

...more

solder bars

1,300 - 3,000 Per Kilogram

300.00 Kilogram (MOQ)

We are manufacturing Soft Solder in the form of Sticks, Ingots & Bars as per IS:193-2000 Specification. They are used in Electronics, Plumbing & Sheet Metal Work. They are Lead Based Alloys & Lead Free Alloys. The Alloys manufactured by us are as tabulated as follows: - Grade Non-Antimonial Solders, Percent Sn Sb Pb Sn 65 65 + 0.5 0.65 Max Remainder Sn 60 60 + 0.5 0.60 Max Remainder Sn 50 50 + 0.5 0.50 Max Remainder Sn 45 45 + 0.5 0.45 Max Remainder Sn 40 40 + 0.5 0.40 Max Remainder Sn 35 35 + 0.5 0.35 Max Remainder Sn 30 30 + 0.5 0.30 Max Remainder Sn 20 20 + 0.5 0.20 Max Remainder Sn 15 15 + 0.5 0.20 Max Remainder Sn 50 Sb 50 + 0.5 2.5 – 3.0 Remainder Sn 45 Sb 45 + 0.5 2.2 - 2.7 Remainder Sn 40 Sb 40 + 0.5 2.0 – 2.4 Remainder Sn 32 Sb 32 + 0.5 1.6 – 1.9 Remainder Sn 30 Sb 30 + 0.5 1.5 – 1.8 Remainder Sn 18 Sb 18 + 0.5 0.9 – 1.2 Remainder Sn 2 Sb 2 + 0.5 0.2 – 0.5 Remainder Grade Sn Sb Pb Ag Sn 95 Sb 95 + 0.5 4.75 – 5.25 0.07 Max 0.02 Max Constituent Grade, Percent Sn 38 Sn 2 Tin 38 + 0.5 2 + 0.25 Antimony, Max 0.06 0.06 Arsenic, Max 0.015 0.015 Iron, Max 0.02 0.02 Alumnium, Max 0.001 0.001 Zinc, Max 0.003 0.003 Cadmium, Max 0.005 0.005 Nickel, Max 0.002 0.002 Bismuth, Max 0.05 0.05 Silver, Max 0.02 0.02 Copper, Max 0.05 0.05 Lead Remainder Remainder

Material : Tin, Solder Sticks,Bars & Ingots,Lead Free Solder Bars & Antimonial Solders

Finishing : Polished

Shape : Bars

Color : Grey, Metalic, Silver, Shiny Silver Or Greyish Silver,Silvery White

Application : Industrial, Electronics,Plumbing & Sheet Metal Work

Feature : Corrosion Resistance, Eco Friendly, Fine Finish, Good Quality, Highly Durable, Perfect Shape

Pattern : Solder Bars

Type : Solder Sticks

Coating : Non Coated, Smooth Casting Die Finish

Country of Origin : India

...moreSilicon Copper Alloy Ingots

650 - 950 Per kilogram

300.00 Kilogram (MOQ)

We are manufacturing Copper Silicon Alloys as per IS:5743-1991 Reaffirmed 2006. When Copper is alloyed with Silicon, the later provides fluidity properties to the alloy prepared as well as significantly increases the strength of the alloy and makes it corrosion resistant. Silicon removes the oxygen from Copper when worked. In our foundry we are manufacturing 2 alloys of Silicon Copper namely CuSi10 which contains 9.0-11.0 Percent Silicon & CuSi15 containing 14.0-16.0 Percent Silicon. The master alloys ingots prepared are in the form of notched Bars Or as required by the Purchaser. The Ingots formed are reasonably uniform in quality and free from dross, flux and other harmful contamination. They are used in applications like marine hardware, electrical & architectural components.

Country of Origin : India

Type : Copper Silicon Alloys

Material : Copper With Principal Alloying Element Silicon Constituting 99.50 Percent Of The Alloy

Shape : Rectangular, Square, In The Shape Of Ingots & Notched Bars

Application : Aircraft, Electrical Appliances, Home Decor, Increase Fluidity

Color : Brown, Brown With Silver & Reddish Shades

...moreSilicon Bronze Ingot

825 - 930 Per Kilogram

300.00 Kilogram (MOQ)

We are manufacturing a range of Silicon Bronze Alloys Ingots. They are tabulated in the following table: - Copper Alloys Standard Cu Sn Pb Zn Fe Ni P Al Mn Si Sb S C63400 ASTM Remainder 0.2 0.05 0.5 0.15 0.15 2.6-3.2 0.25- 0.45 C63600 ASTM Remainder 0.2 0.05 0.5 0.15 0.15 3.0-4.0 0.7-1.3 C63800 ASTM Remainder 0.05 0.8 0.2 0.2 2.5-3.1 0.1 1.5-2.1 C64200 ASTM Remainder 0.2 0.05 0.5 0.3 0.25 6.3-7.8 0.1 1.5-2.2 C64210 ASTM Remainder 0.2 0.05 0.5 0.3 0.25 6.3-7.0 0.1 1.5-2.0 C87300 ASTM 94.00----- 0.2 0.25 0.2 0.8-1.5 3.5-4.5 C95600 ASTM 88.00----- 0.25 6.0-8.0 1.8-3.2 C94700 ASTM 85.00-90.00 4.5-6.0 0.1 1.0-2.5 0.25 4.5-6.0 0.05 0.005 0.2 0.005 0.15 0.05 C94800 ASTM 84.00-89.00 4.5-6.0 0.3-1.0 1.0-2.5 0.3 4.5-6.0 0.05 0.005 0.2 0.005 0.15 0.05

Size : 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, ASTM, BS

Type : Silicon Bronze Alloys Ingots

Material : Bronze

Shape : Rectengular, Square, In The Shape Of Ingots

Weight : 1-100kg

Grade : ASTM, BS, Alloy Designations Are Presented In The Form Of Table

Color : Brown, Shiny Brown Colour

Purity : Silicon Bronze Is An Alloy Of 96 Percent Copper,Silicon,Manganese,Tin,Iron & Zinc.

Condition : New

Surface Finishing : Non Polished, Ingots Are Hammered To Remove Surface Irregularities & Dirt & Dross

Country of Origin : India

Application : Decorative Metal, Marine Hardware, Electrical Components, Chemical Processing Equipments, Etc.

Chemical Composition : Copper Alloyed With Silicon, Manganese, Tin, Iron & Zinc.

...more

Phosphorous Bronze Split Bush

7,895 - 19,895 Per Piece

20 Piece (MOQ)

Phosphorous Bronze Split Bushes are cast as per IS:28-1985 Specification. They are required as Cam Wheel Split Bush & Bush for Journal Bearings. Split Bronze Bearings are required in multiple industrial applications. They aid in absorption of shock, reduction of vibration and noise. The split bushing design could eliminate the need for additional lubrication methods as well as reduce the amount of maintainence needed for optimal operation. Split Bushings are also used where a 2 piece housing is present or where quick assembly and easy installation is required. There are 3 types of split bushings namely perfect halved bushings, matched halved bushings and bushings that are split after machining. Perfect halved split bushings will yield 2 halves of the exact same size. These halves will also match with any other halves manufactured under the same specification. With perfect half split bushings, the halves are interchangeable with any of the other same size halves. Matched halved bushings will match with the corresponding opposite half that had been manufactured with it. Split after machining are the most economical of the 3 types. The material requirement for these parts are the same as non split bushings where the only extra effort lies in the added operation of cutting. The matched and perfect halved bushings start with a larger stock size than what would be used for a split after machining bushing. The bar stock is cut before machining after which they are welded together. The larger beginning stock size will make up for the size loss during the cutting stage. After welding the 2 stock bar halves are machined to finished dimensions. The 2 halves are then separated. This leaves us with 2 halves that will comoplete a 360 Degree Circle. Perfect halved bushings are the least economical and generally are only specified where the split line is critical to the application. They are manufactured in a similar fashion as the matched halves but special attention is paid to make sure that each half is split at the exact centerline and at the same angle as all the other pairs. The process results in halves which are interchangeable amonst one another.

Country of Origin : India

Type : Linear Bush With Sleeve Bearings

Material Grade : BS, IS, ASTM Grades

Corrosion Resistance : Yes

Rust Resistance : Yes

Brand Name : RJMI

Material : Bronze

Shape : Half Pallah Bushes Often With Sleeve Bearings

Certification : Certified By ISO:9001-2015 Standards.

Color : Colour Of Phosphorous Bronze

Pattern : Cast Using Wooden Pattern Suitable To Preparing The Mould

Finishing : Proof Machined

Warranty : 1 Year

Connection : The 2 Halves Are Joined In Convex Ends.

Overall Weight : 12 Kg - 300 Kg

Dimension : As Per Size Of Each Half To Be Joinedand Welded After Machining.

Specialities : Proof Machined To Join Exactly With Its Matching Half

Packaging Type : Wooden Crate Packing

Size (Inches) : As Per Sizes Required By Customer's Drawings & Specifications

Outer Diameter : As Per Sizes Required By Customer's Drawings & Specifications

Thickness : As Per Sizes Required By Customer's Drawings & Specifications

Usage : Automobile Industry, Industrial Applications

Length : As Per Required Size

Inner Diameter : As Per Required Size

Overall Height : 200mm, Upto 200mm & Above

Technique : Casting & Machining

Tensile Strength : Standard

Tolerance : Standard

Hardness : Suitable & Annealed When Required

Density : 8.91 Gram/cc At 20 Degree Centigrade

...more

Phosphorous Bronze Rods

985 - 1,275 Per Kilogram

300.00 Kilogram (MOQ)

Phosphorous Bronze Rods are manufactured by us for Five Different Grades of IS:28-1985 Or Latest Specifications. Phosphorouos Bronze contains of Copper alloyed with Tin, Phosphorous, Zinc & Lead. Rods manufactured by us range from Diameter of 20mm to 300mm & Length of Up to 500mm. The Rods Contain Optimum Chemical & Mechanical Properties to be used for Industrial Purposes and electrical applications. The Rods are often used for manufacturing wires and bars by continuous casting, extrusions/hard drawn processes in Industries. The Rods manufactured have Good Electrical Conductivity, Excellent Resistance to Corrosion & Fatigue, Excellent Strength and performance, fine grain structure and excellent elasticity. The Rods are annealed to impart optimum physical properties.

Size : 25mm Diameter To 300mm Diameter & Up To 500mm In Length

Country of Origin : India

Type : Bronze Rods, Phosphorous Bronze Rods

Material : Bronze, Phosphorous Bronze As Per IS:28-1985 Or Latest Specifications

Shape : Round

Thickness : 100-200mm, 200-300mm, They Are Cast In Diameters Ranging From 25mm To 300mm

Length : 1-1000mm, The Rods Are Cast For Maximum Length Of 500mm

Application : Electrical & Industrial Applications

Color : Brown, Golden, Reddish Orange

Technique : Chill Die Cast & Forged Within A Length Of Upto 500mm

Certifiacation : ISO:9001-2015 Certified

Brand Name : Our Own Brand

Diameter : 25mm - 300mm

Grade : As Per IS:28-1985 Specification & Grades 1 To 5

Density : 8.91 Grams/CC At 20 Degrees Centigrade

Dimension : 25mm To 300mm In Diameter & 150mm - 500mm In Length

Method : Non Continuous Cast & Proof Machined

...more

Phosphorous Bronze Plates

8,895 - 25,000 Per Piece

10 Piece (MOQ)

We are casting Phosphorous Bronze Plates as per IS:28-1985 Specification. Phosphorous Bronze Plates cast by us range from "600mm Length X 400mm Width X 16mm Thickness" to "1000mm Length X 1000mmWidth X 50mm Thickness. They are cast maintaining machinable tolerances and customized as per various applications and conditions of use. We have supplied Phosphorous Bronze Plates to Indian Railways chiefly in applications where they come of use in Girders for Railway Bridges. They are also used for Masonry Fixings, Shafts & Gears, Valve Parts, Electrical Springs, Marine & Chemical Hardware, Spring Washers, Electrical Conductors & Switches, Decorative Items.

Content in the Box : Phosphorous Bronze Plates

Number of Pieces : 2

Surface Finish : Polished & Surface Made Free From Blowholes & Other Impurities

Usage/Application : Girders For Railway Bridges, Electrical Springs, Spring Washers Etc.

Brand Name : Our Own Brand

Material : Phosphorous Bronze as per IS:28-1985 Or Latest Specifications & as per Grades 1 to 5

Color : Colour imparted bby the alloy properties & percentage compositions and post machining

Shape : Rectangular Plates

Type : Cast Plates

Feature : High Wear Resistance, High Fatigue Resistance & Excellent Forming Properties & Weldability

Size : Up To 1 Meter In Length, 1 Meter In Width

Thickness : Up To 64mm Thickness

Pattern : Rectangular Pattern

Weight : Up To 300.00 Kg Per Plate

Country of Origin : India

...more

phosphorous bronze flanges

8,895 - 18,985 Per Piece

300.00 Kilogram (MOQ)

We are manufacturing Phosphorous Bronze Flanges & Flanged Bushes as per IS:28-1985 Or Latest Specifications. Stores are manufactured as per Grade 1, Grade 2, Grade 3, Grade 4, Grade 5. The castings are prepared as per quality and drawings and even customised to meet increasing market demands. Phosphorous is an alloy which has good machinability and excellent strength for bearing heavy workloads. Our Firm is chief engineered by Phosphorous Bronze Castings Of which Flanges meet 70% of demands from our Customers. They are used in applications involving sleeve bearings, thrust washers and cam followers.

Country of Origin : India

Size : 10Inch

Type : Bronze Flange

Material : Bronze

Diameter : 90-100mm, 80-90mm, 70-80mm, 60-70mm, 50-60mm, 40-50mm, 30-40mm, 20-30mm, 10-20mm, 0-10mm

Shape : Round

Thickness : 5-10mm, 10-15mm, 0-5mm, As Per Customer's Drawings & Requirements

Certification : ISO:9001-2015 Certified

Application : Industrial Use, Fittings, Automobiles Use, Electrical Installations

Grade : IS

Color : Golden-Brown

Feature : High Tensile, High Quality, Hardend & Temper, Dimensional, Corrosion Resistance, Auto Reverse, Accuracy Durable

Technics : Castings Are Proof Machined As Per Drawings

Condition : New

Surface Finishing : Polished

Grade : As Per IS, BS, ASTM & DIN Specifications

...more

phosphorous bronze bush

1,495 - 2,985 Per Piece

300.00 Kilogram (MOQ)

We are casting Phosphorous Bronze Bush as per IS:28:1985 Or Latest Specifications according to Grade 1, Grade 2, Grade 3, Grade 4, Grade 5. Phosphorous Bronze is an exceptionally strong and resilient metal making it suitable for Products with required fatigue resistance and against wear & chemical corrosion/exposure to the elements. We are manufacturing Bushings/ Bushes to Length of Upto 500mm. Phosphorous Bronze Bushes are plastic in nature which makes them ideal for heavy load applications. The Bushes/Bushings manufactured by us have charatteristics like dimensional & rotational accuracy, high tensile strength & have the ability to withstand high Temperatures & Pressure.

Country of Origin : India

Size : 2inch, 4inch, 6inch, 8inch, More Than 8 Inches In Diameter & Length

Type : Bronze Bushes, Phosphorous Bronze Bushes/Bushings

Material : Bronze, Phosphorous Bronze As Per Grades 1 To 5

Shape : Round

Thickness : 10-15mm, 15-20mm, 5-10mm, Thcikness May Vary From 10-15mm To 500mm Lengthwise

Application : Electrical Compoenents, Electrical & Industrial Applications

Color : Golden, Yellowish Brown

Feature : Corrosion Proof, Easy To Fit, Fine Finishing, High Durable, Optimum Quality, Robust Construction, They Are Wide Applications In Lubricating Regions Where They Have To Bear Heavy Loads Of Work

Condition : New

Finishing : Non Polished, Slag & Other Harmful Contaminations

Standard : ASTM, BS, IS & BS Specifications

Brand Name : Our Own Brand

Bore Size : 10mm - 1500mm

Precision Rating : Precisely Rated For Their Quality And Good Performance

Seals Type : They Are Sealed With Our Brand

Shaping Mode : They Are Shaped In Round Diameter In Terms Of OD & ID & Definite Length

...more

Phosphorous Bronze Ingot

850 - 1,350 Per Kilogram

300.00 Kilogram (MOQ)

Phosphorous Bronze Ingots cast as per IS:1458-1985 Reaffirmed 2006, Class -1, IS:28-1985 Or Latest Specifications having Grade -1, Grade -2, Grade – 3, Grade – 4, Grade – 5. Chemically they represent the following compositions as follows: - Constituent IS:1458-1985 Reaffirmed 2006 Constituent IS:28-1985 Or Latest Specifications Class 1 Grade 1 Grade 2 Grade 3 Grade 4 Grade 5 Tin 6.0 – 8.0 Tin 6.0 – 8.0 10.0 Min 6.5 – 8.5 9.0 – 11.0 11.0 – 13.1 Lead 0.5 Max Phosphorous 0.30 – 0.50 0.50 Min 0.30 Min 0.15 Max 0.15 Min Zinc 0.5 Max Lead 0.25 Max 0.25 Max 2.0 – 5.0 0.25 Max 0.50 Max Phosphorous 0.4- 0.6 Zinc 0.50 Max 0.05 Max 2.0 Max. 0.05 Max 0.30 Max Iron 0.3 Max Nickel 0.70 Max 0.10 Max 1.0 Max 0.25 Max 0.50 Max Antimony 0.1 Max Iron 0.30 Max 0.10 Max 0.15 Max Iron & Antimony Aluminium 0.01 Max 0.01 Max 0.01 Max Aluminium 0.01 Max Antimony 0.10 Max Total of Other Elements including Iron & Antimony 0.6 Max Silicon 0.02 Max 0.02 Max 0.02 Max Total Impurities 1.20 Max 0.60 Max 0.50 Max 0.80 Max 0.20 Max Copper Plus Incidental Nickel Remainder Copper Remainder Remainder Remainder Remainder Remainder

Size : 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, ASTM, BS, As Per IS:1458-1985

Type : Bronze Ingot, Phosphorous Bronze Alloys Ingots As Per IS:1458-1985 Reaffirmed 2006 & IS:28-1985 Or Latest

Material : Bronze

Shape : Rectengular, Square, Shape Of Plates

Weight : 1-100kg, 10Kg - 12Kg

Grade : ASTM, BS, Grade 5

Color : Brown, Golden, Metallic, Red, Reddish Orange Colour

Purity : Nickel & Phosphorous

Condition : New, Melt & Cast In Moulds As Per Required Size; Its Used For Remelting To Manufacture Castings

Surface Finishing : Non Polished, Dross & Other Harmful Contaminations

Country of Origin : India

Brand Name : Our Own Brand

Application : The Ingots Prapared Are Remelted & Alloyed To Produce Industrial Castings & Other Products

Dimension : As Per Customer's Required Drawings,

Chemical Composition : As Per Grade 1, Grade 2, Grade 3, Grade 4, Grade 5.

...more

Naval Brass Rod

650 - 850 Per Kilogram

300.00 Kilogram (MOQ)

We are manufacturing Naval Brass Rods as per Drawings & Specific applications. Nava Brass refers to a Copper Alloy of Around 59% Copper, 40% Zinc & 1% Tin with a trace amount of Lead. Naval Brass is an alloy which falls into the subfamily of Brasses known as Alpha Beta or Duplex Brasses. These Alpha Beta Brasses are generally harder & strong than non alpha beta brasses. Naval Brass Rods are required for seawater applications. The presence of Lead in Naval Brass improves the corrosion resistance properties of the Material. C464 Naval Brass Rods has a fair machinibility with about 35% of Free Machining Brass. In Our Firm, we are manufacturing Naval Brass Rods Up To 500mm in Length of each rod and diameter from 30mm to 100mm. Naval Brass Rods are required in propeller shafts, marine hardware, decorative fittings, shaftings, propeller shafts and turn buckles. They are also used in many other industrial applications like welding rods, condenser plates, structural uses, valve stems, balls, heat exchanger tubes, aircraft turnbuckel barrels, dies & many more.

Shape : Round

Thickness : 80-160mm,40-80mm,20-40mm,10-20mm

Type : Naval Brass

Material : Brass

Color : Yellowish Golden Colour

Feature : Corrosion Resistance, Rust Proof,High Tensile,High Quality,Heat Resistance,Hardend & Temper,Durable,Dimensional

Country of Origin : India

Grade : BS, IS Specification

...more

Manganese Bronze Alloy

720 - 1,400 Per Kilogram

300.00 Kilogram (MOQ)

We are casting Manganese Bronze Alloys Ingots & Castings as per Chemical Compositions as tabulated below: - Copper Alloys Standard Cu Sn Pb Zn Fe Ni P Al Mn Si Sb Impurities C86550 ASTM 57.0 Min 1.0 0.5 Remainder 0.7-2.0 1.0 0.5-2.5 0.1-3.0 0.1 C87655 EN 56.0-64.0 0.8 0.5 Remainder 0.5-1.8 6.0 0.02 0.7-2.2 0.5-2.5 0.1 0.06 C86300 ASTM 60.0-66.0 0.20 0.20 22.0 – 28.0 2.0-4.0 1.0 5.0-7.5 2.5-5.0 HTB-1 BS:1400-1985 55.0 Min 1.00 0.5 Remainder 0.7-2.0 1.0 0.5-2.5 0.1-3.0 0.1 0.2 HTB-2 BS:1400-1985 55.0 Min 0.2 0.2 Remainder 1.5-3.25 3.0-6.0 4.0 0.1 0.2 HTB-3 BS:1400-1985 55.0 Min 0.2 0.2 Remainder 1.5-3.25 1.0 3.0-6.0 1.5-4.0 0.1 0.2

Brand Name : RJMI

Type : Manganese Bronze Alloys Ingots

Material : Bronze

Certification : Certified By ISO:9001-2015 Standards

Application : Oil & Gas Industries

Grade : ASTM, BS

Color : Warm Yellow Colour

Feature : Corrosion Resistance, High Tensile, High Strength With Excellent Corrosion Resistance

Technics : Melting & Casting Metals

Finishing : Dirt & Dross

Country of Origin : India

...more

Magnesium Ingot

300,000 - 450,000 Per metric ton

1 Metric Ton (MOQ)

Magnesium is a shiny grey metal having a low density, low melting point & high chemical reactivity. Like other alkaline earth metals, it occurs in combination with other elements. It almost has an oxidation state of +2. It reacts readily with air to form a thin magnesium coating of magnesium oxide that inhibits furthur coating of the material. The free metal burns with a bright white light. The metal is obtained mainly by electrolysis of magnesium salts obtained from Brine. It is less dense than Aluminium and is used primarily as a component in strong and lightweight alloys that contain aluminium. Magnesium is used in refining metals such as Zirconium & Hafnium. High Purity of magnesium is required for High Quality Refining. Alloys of magnesium have been used in various products including airplanes & performance cars. Magnesium Ingots are used in the production of magnesium alloys as well as for use in Chemical Industrial, military industrial, meter-instrument manufacture, etc. In Our Foundry, we are stocking Magnesium for our own consumption as well as for reselling. We are offering Magnesium Ingots at fair prices to our customers who not only come to us from within the state but throughout India.

Strength : In Its Pure Form It Lacks Sufficient Strength For Most Structural Applications

Form : In The Shape Of Ingots

Composition : Pure Magnesium 99.999 Percent

Product Name : Magnesium Ingots

Storage : Storage Areas Should Be Well Drained, Kept Grass & Weeds Free & Combustible Materials

Packaging : Packed In Gunny Sacks & Then Enclosed In Wooden Crates For Oversea Shipping

Size : 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, ASTM, BS, DIN

Type : Magnesium Ingot

Material : Magnesium

Shape : Rectengular, Square

Application : Chemical Industries,Military Firms,Meter Instrument Manufacturing Sector,Etc.

Weight : 1-100kg

Grade : ASTM, BS

Color : Grey, White, Greyish White

Purity : Magnesium: 99.999 Percent

Condition : New

Surface Finishing : Polished

Country of Origin : India

Certification : Our Products Are Certified By ISO:9001-2015 Standards

Item : Pure Magnesium Ingots

...more

LM Series Aluminium Ingot

270 - 780 Per Kilogram

300.00 Kilogram (MOQ)

LM Alloy Name ISO Cu Mg Si Fe Mn Ni Zn Pb Sn Ti Aluminium Others LM 0 Al 99.5 0.03 0.03 0.3 0.4 0.03 0.03 0.07 0.03 0.03 Al 99.50 Min LM 2 Al-Si10Cu2Fe 0.7-2.5 0.3 9.0-11.5 1.0 0.5 0.5 2.0 0.3 0.2 0.2 0.5 LM 4 Al-Si5Cu3 2.0-4.0 0.2 4.0-6.0 0.8 0.2-0.6 0.3 0.5 0.1 0.1 0.2 Remainder 0.2 LM 5 Al-Mg5Sil AlMg6 0.1 3.0-6.0 0.3 0.6 0.3-0.7 0.1 0.1 0.05 0.05 0.2 Remainder 0.2 LM 6 Al-Si12 Al- Si12Fe 0.1 0.1 10.0-13.0 0.6 0.5 0.1 0.1 0.1 0.05 0.2 Remainder 0.2 LM 9 Al-Si10Mg 0.2 0.2-0.6 10.0-13.0 0.6 0.3-0.7 0.1 0.1 0.1 0.05 0.2 Remainder LM 12 AlCu10Si2Mg 9.0-11.0 0.2-0.4 2.5 1.0 0.6 0.6 0.5 0.1 0.1 0.2 Remainder 0.2 LM 13 Al-Si12Cu Al- Si12CuFe 0.7-1.5 0.8-1.5 10.5-13.0 1.0 0.5 1.5 0.5 0.1 0.1 0.2 Remainder LM 16 Al-Si5Cu1Mg 1.0-1.5 0.4-0.6 4.5-5.5 0.6 0.5 0.25 0.1 0.1 0.05 0.2 Remainder LM 20 Al-Si12Cu Al- Si12CuFe 0.4 0.2 10.0-13.0 1.0 0.5 0.1 0.2 0.1 0.1 0.2 Remainder LM 21 Al-Si6Cu4 3.0-5.0 0.1-0.3 5.0-7.0 1.0 0.2-0.6 0.3 2.0 0.2 0.1 0.2 Remainder LM 22 Al-Si5Cu3 2.8-3.8 0.05 4.0-6.0 0.6 0.2-0.6 0.15 0.15 0.1 0.05 0.2 Remainder LM 24 Al-Si8Cu3Fe 3.0-4.0 0.3 7.5-9.5 1.3 0.5 0.5 3.0 0.3 0.2 0.2 Remainder LM 25 Al-Si7Mg 0.2 0.2-0.6 6.5-7.5 0.5 0.3 0.1 0.1 0.1 0.05 0.2 Remainder LM 26 Al-Si9Cu3Mg 2.0-4.0 0.5-1.5 8.5-10.5 1.2 0.5 1.0 1.0 0.2 0.1 0.2 Remainder LM 27 Al- Si7Cu2Mn0.5 1.5-2.5 0.35 6.0-8.0 0.8 0.2-0.6 0.3 1.0 0.2 0.1 0.2 Remainder LM 28 Al- Si19CuMgNi 1.3-1.8 0.8-1.5 17.0-20.0 0.7 0.6 0.8-1.5 0.2 0.1 0.1 0.2 Remainder LM 29 AlSi23CuMgNi 0.8-1.3 0.8-1.3 22.0-25.0 0.7 0.6 0.8-1.3 0.2 0.1 0.1 0.2 Remainder LM 30 Al- Si17Cu4Mg 4.0-5.0 0.4-0.7 16.0-18.0 1.1 0.3 0.1 0.2 0.1 0.1 0.2 Remainder LM 31 Al-Zn5 0.1 0.5-0.75 0.25 0.5 0.1 0.1 4.8-5.7 0.05 0.05 0.25 Remainder Cr: 0.4-0.6, Each Other Element: 0.05, Total of Other Elements: 0.15.

Country of Origin : India

Size : 20x3inch, 25x4inch, 30x5inch, 35x6inxh, 40x7inch, ASTM, BS, ISO Designations

Type : Aluminium Alloys LM Series Alloys

Material : Aluminium Alloys LM Series

Shape : Rectengular, Square, Shape & Dimensions As Per Drawings Pattern

Weight : 1-100kg

Grade : ASTM, BS, Aluminium LM Series

Color : Silvery White & Glossy

Purity : Aluminium LM Sesries

Condition : New

Surface Finishing : Non Polished, Polished

Brand Name : RJMI

Application : Electrical Module Packaging, Automotive Body Structure, Wind & Solar Energy Management Etc.

Chemical Composition : As Per LM Series Of Aluminium Alloys

...more

Lead Tin Bronze Ingot And Castings

783 - 985 Per Kilogram

300.00 Kilogram (MOQ)

Leaded Tin Bronze Alloys are cast as per IS:318-1981 Reaffirmed 2006 specification. This specification covers 6 Grades of Leaded Tin Bronze Alloys for Ingots & Castings. Castings done by us are Bushings, Rods, Flanges & Castings as per drawings & dimensions. The Ingots formed are of uniform quality and reasonably free from slag, dross and other harmful contaminations. The Castings formed are clean & free from harmful defects, blowholes, gas cavities etc. The chemical composition for the Five Grades is tabulated as under: - Constituent LTB -1 LTB-2 LTB-3 LTB-4 LTB-5 LTB-6 Tin 6.0-8.0 4.0-6.0 6.0-8.0 6.0-8.0 9.0-11.0 4.0-6.0 Zinc 1.5-3.0 4.0-6.0 0.75 Max 0.75 Max 1.0 Max 1.0 Max Lead 2.5-3.5 4.0-6.0 9.0-11.0 14.0-16.0 8.5-11.0 18.0-23.0 Nickel 2.0 Max 2.0 Max 2.0 Max 2.0 Max 2.0 Max 2.0 Max Aluminium 0.01 Max 0.01 Max 0.01 Max ------- 0.01 Max ---------- Silicon 0.01 Max 0.02 Max 0.02 Max 0.02 Max 0.02 Max 0.01 Max Antimony 0.3 Max 0.4 Max 0.5 Max 0.5 Max 0.5 Max 0.5 Max Iron 0.30 Max 0.35 Max 0.35 Max 0.35 Max 0.35 Max 0.35 Max Total of all Impurities 0.70 Max, (Excluding Nickel) 0.80 Max, (Excluding Nickel) 0.80 Max (Excluding Nickel + Zinc) 0.80 Max, (Excluding Nickel + Zinc) 0.80 Max (Excluding Nickel + Zinc) 0.80 Max (Excluding Nickel + Zinc) Grade LTB 1 & LTB 2 are meant for general castings and have fair strength and good machining properties. They are used in Valve fittings & pump castings. Grade LTB 3 is suitable for High speed & heavy pressure bearings. Grade LTB 4 is used for General Castings in moderate pressure applications and general-purpose bearing metal. Grade LTB 5 is used for hard or moderately hard shafts with loads and speeds moderate or low with rather less adequate lubrication and alignment. Grade LTB 6 is used for bearing under light loads and high Speeds.

Country of Origin : India

Type : Tin Bronze Alloys

Material : Bronze

Grade : BS, IS

Color : Yellowish Brown

Application : Automobiles, Automotive Industry, Fittings, And Many Other Industrial Applications

...more

High Tensile Brass Rod

850 - 1,250 Per Kilogram

300.00 Kilogram (MOQ)

We are manufacturing High Tensile Brass Rods & Sections as per IS:320-1980 Specification. In our Foundry, we are casting High Tensile Brass Rods & Sections in dimensions ranging from 30mm to 180mm in Diameter & Upto 500mm in Length. The Condition of delivery of High Tensile Brass is as manufactured and proof machined and sometimes annealing them to meet the properties as required by the Buyer. High Tensile Brass is a Copper Zinc Alloy which combines with Additives to increase the Tensile Strength over that of the simple binary Copper Zinc Brass. The Chemical Composition of the alloys under Grades as per specification are tabulated as below: - Constituent Percentage Composition Grade HT-1 Grade HT-2 Copper Plus Incidental Nickel 56.0 – 60.0 56.0 - 61.0 Tin 0.2 – 1.0 1.0 Max Lead 0.20 – 1.5 0.50 – 1.5 Iron 0.20 – 1.25 0.20 – 1.5 Manganese 0.25 – 2.0 0.50 – 2.0 Aluminium 0.20, Max 0.3 – 2.0 Antimony 0.02 Max 0.02 Max Total of Other Elements 0.50 Max 0.50 Max Zinc Remainder Remainder Our Firm is capable of producing High Tensile Brass Solid & Holow Rods.

Type : High Tensile Brass Rods & Sections

Material : Brass, High Tensile Brass

Shape : Round, In The Shape Of Solid & Hollow Rods.

Thickness : 10-15mm, Greater Than 15mm

Certification : Certified By ISO:9001-2015 Standards

Application : Automobiles, Automotive Industry, Construction, Fittings, Industrial, Etc.

Grade : ASTM, BS, IS,Indian Standards Institution

Color : Grey-Golden

Feature : Accuracy Durable, Corrosion Resistance, Dimensional, Hardend & Temper, High Quality, High Tensile

Surface Finishing : Polished

Country of Origin : India

Brand Name : RJMI

Length : Upto 500mm

...more

High Tensile Brass Ingots And Castings

600 - 815 Per Kilogram

300.00 Kilogram (MOQ)

High Tensile Brass Ingots & Castings are cast as per IS:304-1981 Reaffirmed 2006. This standard covers the requirements for 2 Grades of High Tensile Brass Ingots for remelting purposes and castings. The Ingots cast by us are of uniform quality and reasonably free from slag, dross and other harmful contaminations. The Castings prepared are free from harmful inclusions and cracks. High Tensile Brass Ingots are remelted for producing castings for Gas Valves, Fittings, Fasteners, Pump Trim, Gears, Locks, Heavy Duty Electrical Connectors, Transmission Components, Marine Hardware, Safety Tools & Decorative Metal Work. High Tensile Brass Castings are used extensively for wear resisting applications because of their strength. It is also used for marine propellers, pump impellers and valve bodies due to their high corrosion resistance. High tensile Brass is alloyed with aluminium, manganese & silicon which makes it as hard as aluminium bronze and renders easy to process characteristics and machinability. The material when analyzed in accordance with IS:3685-1966 shall have the chemical composition as follows: - Constituent Grade HTB-1 Grade HTB-2 Copper Plus Incidental Nickel, Min 55 55 Manganese, Max 3.0 4.0 Aluminium 0.5-2.5 3.0-6.0 Iron 0.7-2.0 1.5-3.25 Tin, Max 1.0 0.20 Lead, Max 0.50 0.20 Silicon, Max 0.10 0.10 Total of Other Elements, Max 0.20 0.20 Zinc Remainder Remainder

Country of Origin : India

Size : Rods & Bushes Are Cast Up To A Length Of 500mm

Type : Cast As Ingots & Castings As Per Drawing & Application

Material : Aluminium, Iron & Manganese

Shape : Rectangular, Round, Bush Bearing

Color : Yellowish Grey

Brand Name : RJMI

...moreOpening Hours

Being in the industry for more than 4 decades, we R.J.Metal Industries is a Kolkata (West Bengal, India) based organization that is engrossed in offering the finest quality foundry products to our esteemed customers. We are the topmost manufacturer and supplier of a wide range of foundry products such as Phosphorous Bronze Ingots, Phosphorous Bronze Rods, Phosphorous Bronze Bush, Phosphorous Bronze Flanges, Phosphorous Bronze Split Bush, Phosphorous Bronze Plates, Brass Plates, White Metal Ingots, Copper Magnesium Alloy Ingots, Silicon Copper Alloy Ingots, Phosphorus Copper Ingots, Lead Tin Bronze Ingot And Castings, Aluminium Alloy Ingot Casting, LM Series Aluminium Ingot, Aluminium Bronze Ingots And Castings, High Tensile Brass Ingots And Castings, Tin Bronze Ingots & Castings, Copper Silicon Alloys Ingots etc. All these products can be obtained at cost-effective prices worldwide, primarily in the Indian Subcontinent, United Arab Emirates, Nepal, Bhutan, and Bangladesh.

Our Firm was established in the year 1979 under the entrepreneurship of Mr. Manaranjan Das who is the Technical Head. He is a Metallurgical Engineer with a B. E. in Metallurgy and has over 40 Years of Experience in the field. It was under the tutelage of our Founder, that our Firm succeeded in establishing a well-equipped facility for Melting Non-Ferrous Metals and producing Sophisticated Products as per Current Market Demands with Efficiency & Moral Integrity.

R.J.Metal Industries is supported by a skilled labour force who are chiefly dedicated towards their work and it is their honesty & efficiency that have played a major role in making us what we are now. Their hard work and consistency with diligence & quest for knowledge and improvement have been key to our success in the competitive market. Defying all infirmities and hard times, they are wholeheartedly devoted towards their work for further development in knowledge for producing sound quality castings and products.

Our Firm extends over an industrial area of 7500 Square Feet which houses our In House Office, Melting Shop, Go-Down for Storing Incoming Raw Materials & for Finished Materials. It also includes our machine shop where castings are machined and sectioned as per drawings. Besides that, we have a well-equipped Pollution Control System. While much of our raw materials are available in the local market, we are also importing metals from foreign countries. Our Firm is accredited by ISO : 9001-2015 Standards. Our foundry also customizes products by outsourcing for better material properties, sophisticated needs and applications.