Water Tanks

Series CCWS Cylindrical Vertical Tanks with Closed TopAdvantages: Rust proof Light weight and durable Hygienic Maintenance-free Tested and approved by leading laboratories, industries and institutions Available in various capacities from 200 litres to 25,000 litres or even more

...more

Water Storage Tanks

PATTON delivers customer value through a wide array of hygienic, robust and customized plastics products. Water conservation is the most cost-effective and environmentally sound way to reduce our demand for water. PATTON manufactures plastic storage tanks that assists consumers in conserving this precious resource for storage and consumption. ADVANTAGES : PATTON water storage tanks are made of 100% food grade plastic that conforms to USFDA standards that helps the water to retain its original characteristic over a period of time. Advanced technology is used to prepare the tanks in one piece so that there are no joints. This prevents leakage and longevity of the tanks. Inlet and outlet ports are located of flat surfaces which eliminate possibilities of leakage. The tanks are available in various colours and are odour and fungus free. We have launched a highly sophisticated, technologically advanced, newly designed product which is being manufactured by our fully computerized 4-arm machine. Our tank lids are uniquely designed to provide air-tight protection from foreign particles like dust, insects etc. and prevent contamination by airbourne bacteria and viruses. An unique inclusion of underground water storage tanks is that they are specially designed to resist earth pressure and thereby ensure no leakage of water.

...more

triple layer tanks

Unique Features: Multilayer Algae formation protection Attractive looking & packing Durable & economical No maintenance Leak proof Rust proof Moulded to seamless perfection

...more

PVC Pipes

All materials and products have some effect on the environment. As a result society must take balanced approach and carefully weigh the environmental impact against the benefits that are derived from a particular material or product.The three most important raw materials being used by Ori-Plast to produce pipes and fittings are PVC (poly vinyl chloride), CPVC (Chlorinated Poly Vinyl Chloride) and PE (Polyethylene, High and Medium Density), all of which are classified as thermoplastic material, meaning that they can be melted to a liquid and remolded as they return to solid state.All these materials are produced from crude benzene which is obtained as a by-product during distillation of petroleum. Crude benzene is broken down in a heat cracking process into various hydrocarbons including ethylene which is a colour less gas comprising carbon and hydrogen.

...more

Loft Tanks

Series IWS Loft Tanks available in black & white colour Unique Features: Rust proof Light weight and durable Hygienic Maintenance-free Tested and approved by leading laboratory

...more

household drums

Unique Features: Rust proof Light weight and durable Hygienic Maintenance-free Tested and approved by leading laboratory

...more

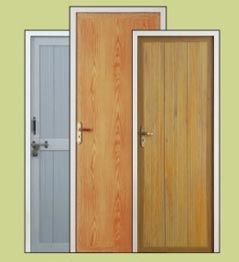

FMD Doors

Unique Features: Reinforced with excellent polymeric reinforcement to avoid weather effects Suitable for toilet, bathroom and kitchen door Options of single & multi panel door Available in all standard shades of SINTEX

...more

Supreme SWR Pipes & Fittings

CPVC Pipes

CPVC or Chlorinated Poly Vinyl Chloride is produced by chlorination of poly vinyl chloride (PVC) resin. In the process, the chlorine gas is decomposed into free chlorinewhich is then reacted with PVC in a post production step, essentially replacing a portion of the hydrogen in PVC with chlorine. The extra chlorine molecule helps to increase its glass transition temperature (Tg) significantly, resulting in a CPVC which is extremely heat resistant. As a result CPVC performs much better in high temperature and high pressure applications than PVC. Some of the advantages of CPVC for piping systems are: Very good chemical and corrosion resistance Outstanding chemical resistance No electrochemical corrosion Long service life, even under intensely corrosive conditions No support microbial growth Simple installation using solvent cementing Smooth inner surface Exceptional flammability resistance No influence on drinking water

...more

Polyethylene Pipes

Polyethylene is also produced from ethylene by way of polymerization. It consists only of carbon and hydrogen (hydrocarbons) and is also referred as polyolefin. It belongs to the semi-crystalline thermoplastics group and when compared with PVC and CPVC (both being amorphous thermoplastics) it show less tensile strength, melting temperature and a lower E modulus. However it exhibits higher impact resistance, elongation at rupture and thermal expansion.It is an environmental friendly hydrocarbon product which does not dissolve in common solvents as well as hardly swells. Thus PE pipes cannot be solvent cemented like PVC and CPVC. The appropriate joining method for polyethylene is welding and commonly used welding techniques are butt fusion welding and electrofusion.Polyethylene pipe materials of medium density (MDPE) to high density (HDPE) are ideal for industrial piping installations and the grades are classified on the basis of their internal pressure resistance e.g. PE 63 (MRS 6.3 MPa), PE 80 (MRS 8.0 MPa) and PE 100 (MRS 10 MPa).The advantages include: Low weight (around 1/8th of steel) Outstanding flexibility Good abrasion resistance Corrosion and chemical resistance High impact resistance even at very low temperature Safe and easy joining by welding Excellent cost effective

...moreBe first to Rate

Rate ThisOpening Hours