Western Pneumatic Tube Company

Western Pneumatic Tube Company is a custom, welded tube mill capable of producing specialty tubing in a wide variety of materials and configurations. At the same time, it is a production facility with capacity for output of tubing of certified quality and integrity. The capability of manufacturing highly specialized tubing to aerospace and laboratory tolerance aswell as the capacity for volume production, provides the moans for flexible and efficient response to a broad range of industry requirements. Features : Our unique capabilities are based on a combination of forming and welding techniques. specifically designed equipment to meet your special production requirements, and on capable people with years of experience in welded tube production. Three basic welding techniques, each contributing unique capabilities and advantages, are employed at Western Pneumatic. Continuous mill forming and welding of stainless steel hollows in a range of diameters of 2 3/8 to 4 1/2 in wall thicknesses of .035" to .120 Semi-continuous ring forming and welding for custom production of high volumes of thin wall tubing in diameters of ?e to 12" with wall thicknesses of .004 to .05Q and in lengths to 40 ft Brake forming for subsequent welding of individual tube lengths in materials. gauges, sizes or quantities not suited to the higher production methods. Tubing from 4:i to 10' in diameter, in wall thickness to .150-can be produced Other facilities include hydraulic draw benches for cold drawing, resizing, or shaping to an unlimited variety of cross-sectional shapes

...more

Weld Nuts

PEM brand weld nuts overcome many problems associated with other weld nuts - burn-outs, complicated electrodes and pilots, tedious time-consuming indexing and re-tapping to remove weld spatter. Their design, based on the experience of hundreds of users of weld nuts, speeds production using standard equipment, thereby reducing labor costs.

...more

THREADED INSERTS PLASTICS

SI®THREADED INSERTS PLASTICS SI inserts are typically specified in applications where strong, durable metal threads are required in plastic material, especially where frequent assembly and disassembly of the unit for service or repair is necessary. Applications for SI® products include: computers and terminal boards, automotive, electronic equipment, business machines, aerospace, communications equipment and instrument cases. • SI inserts are available in brass, stainless steel and aluminum. SI inserts are available in a large variety of ultrasonic / heat staking, molded-in or press-in types. SI inserts meet the strictest quality guidelines which are maintained through in-process audits and adherence to the ISO 9001 and QS-9000 disciplines. Features : ULTRASONIC / HEAT STAKING INSERTS Ultrasonic - Installed by pressing the insert into the mounting hole with ultrasonic insertion equipment while simultaneously applying a high frequency vibration. Frictional heat caused by the vibration melts the plastic surrounding the insert allowing easy insertion. When the vibration ceases, the plastic solidifies, locking the insert permanently in place. Heat Staking - Installed by pressing the insert into the mounting hole with a thermal press to melt the plastic surrounding the insert. MOLDED-IN INSERTS Installed during the molding process, the inserts are located in the mold cavity by core pins. When the mold opens, the core pins are withdrawn leaving the inserts permanently encapsulated in the plastic section with only the threads exposed. Installing the inserts during the molding process eliminates the need for secondary steps or installation equipment. PRESS-IN INSERTS nstalled by simply pressing the inserts into pre-molded or drilled holes. Installation is accomplished using any standard press at any time during the production process. Eliminates the need for molding-in inserts. Eliminates the need for heat or ultrasonic equipment

...more

THIN-WALL LOW-PROFILE HEAD-TYPE AEO

All Dimensions are in inches Features : All Dimensions are in millimeters MATERIAL & FINISH SPECIFICATIONS

...more

THE STICKSCREW SYSTEM

THE STICKSCREW® SYSTEM The StickScrew® system offers manufacturers an extremely fast, accurate and efficient method of small screw insertion. The new and improved StickShooter® driver is designed to accommodate interchangeable nose assemblies. This simple, low cost system combines a lightweight driver and "sticks" of up to 130 per 12" serially connected hex head screws. Simply insert the stick in the driver, advance to the second screw, squeeze the trigger, place the tip of the rotating screw into the hole and the screw is driven home, twisting off cleanly when precise seating torque is reached. Custom screw designs, finishes, and coatings are available to meet the needs of specific applications. Features : The StickScrew® system benefits include: Self-contained system. No expensive tooling, jigs, or fixtures are required. Designed to reduce repetitive motion stress injury. Eliminates manual driving of screws. Torque reliability. Seating torque is built into the screw eliminating torque testing and ensuring the assembly is properly fastened. Minimum operator training. System can be applied to your production line with less than ten minutes training Inventory control simplified. No loose or mixed screws. Less shelf space required. Major productivity increase in small screw insertion. Productivity increases are greater as screw diameters decrease since difficulty in handling loose screws is eliminated. Interchangeable nose assemblies enable quick tooling changeover for all screw hex sizes.

...more

SURFACE MOUNT FASTENERS

PEM® ReelFast® surface mount nuts, spacers, panel fasteners and R'ANGLE®fasteners are mounted to printed circuit boards in the same manner as other surface mount components prior to the solder reflow process. The fasteners are provided on tape and reel compatible with existing SMT automated installation equipment. Nuts and spacers are available in threaded and unthreaded sizes. Features : Benefits of ReelFast® SMT fasteners are: Faster assembly Reduced scrap Reduced handling Reduced risk of board damage that may occur when fasteners are improperly installed with off-line equipment Reduced loose hardware

...more

STANDOFFS SELF CLINCHING

KEYHOLE® STANDOFFS SELF CLINCHING The PEM KEYHOLE® Standoff (Type SKC®) is designed so that a PC board or panel can be quickly slipped into place and then removed from an assembly by simply sliding the board sideways and lifting it off. PEM Keyhole standoffs can save valuable time and dramatically reduce the amount of loose hardware required. Features : These standoffs can be used for spacing or hanging of replaceable components. Typically, several KEYHOLE standoffs are used with one standard PEM threaded standoff which accepts a screw to secure the board or component

...more

Standard and Custom Aluminum Circuit Boards

Aluminum Printed Circuit Boards(III) Standard and Custom Aluminum Extruded Front Panels and Faceplates Our comprehensive range of solutions delivers industry leading value Put Your Best Face Forward Baknor is your first choice in high quality, standard and custom stamped, extruded or cast front panels and faceplates offering a comprehensive range of solutions with industry leading value. From simple metal components to detailed cosmetic parts, Baknor ensures your best face is always brought forward. By delivering rugged product quality through precision tooling design, process engineering and documented quality control, Baknor offers front panels and face plates for virtually any electronics applications. Features : Quick reponse to your needs Creative design solutions Cost advantages Localized inventory management Aggressively pursue price and technolgy improvements Prototyping - Fast and Accurate Baknor has built an enviable reputation for expert prototyping that is fast and accurate. Our prototyping - system provides the assurance you need that the design will function perfectly. Our ability to turn your prototypes into production - from very small volume requirements to high production needs with our complete and systematic prototyping process is proven to deliver results, fast. Insight,Creativity And Esthetics Improve the looks and feel og your faceplates by taking advantage of Baknor's comprehensive manufacturing capabilities and high quality finishes. We can include numerous features into the design that will help your customers identify your brand. Include offsets for shielding strips or clips, square corners, detents for a variety of custom labels, or where ever our creativity may take you. And with numerous variations on cut outs for switches, connectors and LEDs, we can provide you with that special look.

...more

Stainless Weld Nut

PEM brand weld nuts overcome many problems associated with other weld nuts - burn-outs, complicated electrodes and pilots, tedious time-consuming indexing and re-tapping to remove weld spatter. Their design, based on the experience of hundreds of users of weld nuts, speeds production using standard equipment, thereby reducing labor costs.PEM stainless steel weld nuts offer the added advantages of resisting corrosion and being essentially non-magnetic. You may specify steel or stainless steel for your requirements and be sure you are getting the weld nuts that are easiest to install.

...more

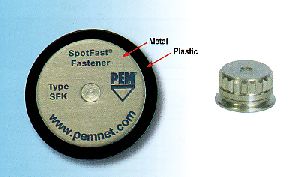

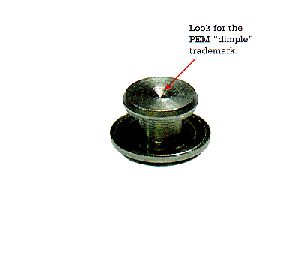

SPOTFASTTM FASTENERS

Replaces riveting or welding. No special installation equipment required. Standard parts install into sheets as thin as .030"/0.8mm. Flush mounted on both sides. Minimal space requirements. Can be installed blind into bottom (panel 2) sheet. Can join dissimilar metals (which otherwise can not be welded). Can be concealed with paints and powder coatings. Can be used as single flush-mounted pivot point. RoHS compliant. Features : The PEM® SpotFast™ self-clinching fastener from PennEngineering creates a permanent, flush joining of two sheets of metal. The fastener installs smooth with the top sheet, and flush or sub-flush with the bottom sheet. Squeezing the fastener into place causes a cold-flow of panel material into the fastener's two separate clinch profiles. This fastener is capable of joining two dissimilar metals, including unequal thicknesses. Rotational by design, the use of a single fastener can also act as a hardened pivot point if so desired.

...more

SpotFast Fasteners(I)

for joining metal to PCB/plastic panels The PEMa SpotFast° fastener from PennEngineering" creates a permanent, flush joining of metal to PCB/plastic Features : Features and Benefits Alternative to riveting and adhesives Standard parts install into metal sheets as thin as .031 "/0.8mm

...more

SpotFast Fasteners

washer allows consistent pivoting of two metal panels The PEM SpotFast' self clinching fastener from Pennfngineering' allows pivoting of two sheets of metal. A wave washer provides the consistent torsion to allow repeatable hinging. The fastener installs smooth with the top sheet, and flush or sub-flush with the bottom sheet. Squeezing the fastener into place causes a cold-flow of panel material into the fastener's two separate clinch profiles. This fastener is capable of joining two dissimilar metals, including unequal thicknesses. Features : Features and Benefits Alternative to riveting Washer allows pivoting with consistent force Standard parts install into sheets as thin as .031"/0.8mm Flush mounted Minimal space requirements Can be installed blind into bottom (Panel 2) panel Can join dissimilar metals RoHS compliant Installations Punch or drill properly sized mounting hole in both panels. Do not perform any secondary operations such as deburring Using only Panel 1, with the punch and anvil surfaces parallel, apply squeezing force until the fastener is flush with the top of Panel 1 Place washer over installed fastener (concave side facing up), then place Panel 2 over fastener. Apply squeezing force. Keep .015-.020" / 0.38-0.51 mm nominal gap between two sheets after installation Part Number Designation Performanes Data

...more

SPINNING CLINCH BOLT

Permanently captivates into sheets as thin as.040" 11.02 mm and greater. Replaces loose hardware Available with jacking feature or axial float feature. Appropriate for close centerline-to-edge applications RoHS compliant Type SCB'"' Spinning Clinch Bolt is a one piece fastener that installs by simply pressing it into a properly sized hole. The controlled clinching action permanently captivates the screw in the panel yet still leaves it to spin freely in the sheet. This allows quick attachment of mating hardware, eliminating much of the need for loose fasteners, such as screws and retaining clips or washers. or expensive multi-component fastener assemblies. The Spinning Clinch Bolt can also be used with the PEM Type N10 receptacle nut (see PEM Bulletin PF) and with the PEM Type RAS R'ANGLEg fastener . Part Number Designation All dimensions are in inches All dimensions are in millimeters Features : Installation Punch or drill properly sized mounting hole in sheet Place the fastener through mounting hole and into anvil. A flat or recessed punch can be used With punch and anvil surfaces parallel, apply squeezing force to the top of the screw head and the underside of the sheet material. The squeezing action forces the shoulder of the screw into the sheet, displacing sheet material, causing it to fill the void under the head and shoulder of the screw All dimensions are in inches All dimensions are in millimeters Performanes Data

...more

Spin Tite rasteners

Improved torque out resistance Easy to install using spin/spin tooling Able to be installed after finish Features a large diameter, low-profile head and knurled shank Offers highest all around strength Same as the AEL but with a minimized-profile head Allows near-flush installations with no need for special hole preparations such as countersinking or dimpling Features : Features Low-Profile head design Achieves flush installations with no need for counter-sink drilling or dimpling of the parent material Works in any thickness over .029'%0.76 mm including blind hole High resistance to torque out Minimal backside protrusion for restricted space applications Provide strong external threads in blind applications Easy to install using spin/spin tooling

...more

Specialty Fasteners

SCREWS are basically classified under 3 major types or categories: MACHINE SCREWS - needs a pre-tapped hole - most commonly used TAPPING SCREWS - needs the hole to be drilled pierced, but not tapped - typical types are taptite screws (used on soft metal or casting), plastite screws (used for plastic) or High-Low screws (normally used on sheet metal). - need to specify the type of point for leading the screw into the hole e.g. type BT, type C or F „ DRILLING SCREWS - do not need a hole (but for positional accuracy, a pilot point is recommended) - typically used in construction industries - drilling screws consists of a drill bit tip followed by a tapping screw body. - eliminates the need to bring work piece to the drill bench to prepare hole. A SEM is an assembly consisting of a screw with one or more washers. Features : How to specify a screw (basic requirement) Head type e.g. Pan head Type of drive e.g. Cross Recess Thread used e.g. M3 or 6-32 Length needed e.g. 10 mm or 0.5" (note: do not mix metric length and unified thread sizes) Type of screw e.g. taptite or machine screws or a SEM Material used e.g. Low carbon steel (LCS) Plating (if any) e.g. zinc clear Optional : Standards e.g. JIS or IFI Note: In all preparation, the precedence priority in terms of quality definition, the following order is adopted: First article approval documentation (which may include deviations) Print or Drawing specifications Part description d. Samples

...more

SNAP TOP STANDOFFS

PEM®SNAP TOP STANDOFFS PEM SNAP-TOP® Standoffs (Types SSA, SSS, SSC, KSSB) are designed for permanent installation into metal panels or PC boards. These all-metal standoffs use a spring action to hold PC boards and subassemblies securely, while allowing for quick removal. Screws and other threaded hardware are eliminated. This means less parts to handle during assembly and less risk of damaging delicate circuitry because of loose parts falling into your equipment. Features : These standoffs are permanently installed in the panel by squeezing them into a punched or drilled hole using any standard press. Installation forces, pushout, and snap forces, are listed on page 6.

...more

Sheet Metal

Gage Conversion Chart Features : Unified/Metric Conversion Unified/Metric Conversion Formulas

...more

Self-locking Fasteners

PEM®self-locking fasteners (Type LK/LKS/LKA) permanently retain their inherent flexing action, permitting repeated use and effective prevailing locking torque. The unique PEMFLEX® self-locking feature with EF or MD finishes, meet the locking torque requirements for 250°F nuts of NASM25027 specification. The self-clinching feature is the same tried and proven design preferred and appreciated for fast, simple assembly. These fasteners do not protrude through the reverse side of the sheet and provide positive, permanent attachment with high torque-out (many times greater than locking torque) and pushout resistances. Features : PEM all-metal, self-locking fasteners are available in steel, stainless steel, and aluminum. Types LK (steel) and LKS (stainless) are treated with a black dry film lubricant for better locking performance. Type LKA (aluminum) must be used with a lubricated screw. The PEM design utilizes two rugged, semicircular flexing jaws instead of several less-supported segments. The greater ruggedness and retention of this PEMFLEX action prevents relaxation and loosening of the fastener in severe service.

...more

SELF-LOCATING PROJECTION WELD NUTS

PEM® weld nuts (Types WN/WNS) provide load-bearing threads in metal sheets too thin to tap, and permit faster assembly. PEM brand weld nuts overcome many problems associated with other weld nuts - burn-outs, complicated electrodes and pilots, tedious time-consuming indexing and re-tapping to remove weld spatter. Their design, based on the experience of hundreds of users of weld nuts, speeds production using standard equipment, thereby reducing labor costs. Features : PEM stainless steel weld nuts offer the added advantages of resisting corrosion and being essentially non-magnetic. You may specify steel or stainless steel for your requirements and be sure you are getting the weld nuts that are easiest to install. A variety of welding equipment is suitable for installation of PEM weld nuts. Best results have been obtained with a 50KVA press-type, spot-welding machine whose upper welding head moves vertically in a straight line with the lower electrode. Flat-faced electrodes with tip diameters .125" / 3.2 mm larger than the "E" dimension of the PEM weld nut should be used.

...more

SELF-CLINCHING STUDS

FH (flush-head) Studs are installed by placing them in punched or drilled holes in the sheets and squeezing into place with any standard press. The squeezing action embeds the head of the stud into the sheet. The metal displaced by the head flows smoothly and evenly around the ribs and into the annular groove - creating a flush-head assembly and securely locking the stud into the sheet with high torque-out and pushout resistances.. Also available unthreaded on special order. Features : TFH (non-flush) Studs are for sheets as thin as .020 inches / 0.51 mm. They may also be used in thicker sheets where flush head studs are not required. TFH studs are installed in the sheets in the same manner as flush-head studs; however, different punches and anvils are required. When installed, the TFH stud will be securely locked into the thin sheet with ample torque-out and pushout resistances. The stud head will not be flush but will project above the sheet surface approximately .025 in. / 0.64 mm. HFH (high-strength) Studs replace weld studs with easier installation at lower costs. The large stud head which projects above the sheet material distributes the axial tightening force over a large area thereby improving pull through resistance. HFHB (BUBAR®) Studs are ideal for applications which demand superior electrical/mechanical attachment points. Phosphor bronze studs offer twice the conductivity of carbon steel studs. FHL (low-displacement head) Studs install closer to the edge of a sheet than standard studs without causing that edge to bulge. Depending on thread size, Type FHL studs can be installed from 25% to 50% closer to the edge of a sheet than standard self-clinching studs. FH4 & FHP (flush-head) Studs for Sterols Steel are designed to provide strong threads in stainless steel sheets as thin as .040" / 1 mm. Type FHP studs have high corrosion resistance. Both types are designed for use in stainless steel sheets with a hardness of 92 or less on the Rockwell "B" scale. TPS (flush-head) Pilot Pins satisfy a wide range of positioning, pivot, and alignment applications. The chamfered end makes mating hole location easy. HFE (high-strength) Studs are designed with an enlarged head diameter to provide high-strength in sheets as thin as .040" / 1 mm. Dog Point and Anti Cross-Thread Options.

...more

SELF-CLINCHING STANDOFFS

These standoffs, which use the proven self-clinching design, install with a squeeze in punched or drilled round holes - and become permanently mounted in the thin sheet. PEM® brand thru-hole threaded standoffs are installed with their heads flush with one surface of the mounting sheet. When blind-threaded types are used, outer sheet surfaces are not only flush, but closed as well. Unthreaded standoffs are also available for spacing multi-panel assemblies. Types S04 and BSO4 standoffs are for installation into stainless steel sheets as thin as .040" / 1.02 mm. Types TSO, TSOS, and TSOA self-clinching threaded standoffs provide permanent threads in sheets as thin as .025" / 0.63 mm. PEM self-clinching standoffs are also available on special order in non-heat treated carbon steel as type SON (thru-hole threaded) or BSON (blind threaded). Types DSO and DSOS standoffs are available for close-to-edge applications. If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need. Features : For other types of PENT brand standoffs and spacers see: Bulletin CH PEM® Concealed-head Standoffs. Bulletin K PEM® Standoffs for printed circuit boards. Bulletin SK PEM® KEYHOLE® Standoffs. Bulletin SMT PEM® ReeIFast SMT Spacers/Nuts. Bulletin SSA PEM® brand SNAP-TOP® Standoffs.

...more

self clinching standoff

These standoffs, which use the proven self-clinching design, install with a squeeze in punched or drilled round holes - and become permanently mounted in the thin sheet. Threaded standoffs are installed with their heads flush with one surface of the mounting sheet. When blind-threaded types are used, outer sheet surfaces are not only flush, but closed as well. Unthreaded standoffs are also available for spacing multi-panel assemblies.

...more

SELF-CLINCHING, SHEET JOINING FASTENERS

SELF-CLINCHING, SHEET JOINING FASTENERS Allows detachable joining a1 two sheets Clinch feature mounts fastener permanently into metal sheet Unique barrel design allows for quick "panel-on-panel" attachment and detachment Head is flush or sub-flush with one side of metal sheet. Can be clinched into blind hole where concealed-head is required Makes horizontal or vertical component mounting possible The PEM KEYHOLES sheet joining fastener. Type SKC-P", is designed so that two sheets can be quickly joined flat against each other and then can be removed from the assembly by simply sliding the sheet sideways and lifting it off. Typically, several KEYHOLE'S sheet joining fasteners are used with one standard PEW threaded Type F flush nut which accepts a screw to secure the sheets against any unwanted movement Installations Punch or drill properly sized mounting hole in Panel Place the fastener into anvil hole as shown in the drawing to the right Place the panel over the shank of the fastener With the punch and anvil surfaces parallel, apply only enough squeezing force until flange is flush with panel Blind Hole Installation Procedure Mill a blind hole to .043"/ 1.1mm deep Place the fastener into anvil hole as shown in the drawing to the right Place the panel over the shank of the fastener With the punch and anvil surfaces parallel, apply only enough squeezing force until flange is flush with panel Features : All Dimensions are in inches All dimensions are in millimeters All Dimensions are in inches All dimensions are in millimeters Performances Data

...more

self-clinching nuts

For load-bearing threads in thin sheets - aluminum, steel, and other ductile materials. Proved Performance For over 60 years, PEM brand self-clinching fasteners have satisfied production and fastening requirements wherever load-bearing threads are required in thin metal sections too thin to tap. Quick, convenient assembly using standard tools Installation of PEM brand self-clinching nuts is simple, quick, and convenient. Just insert them in punched or drilled holes, then apply a squeezing force to embed the clinching ring completely in the sheet metal. Features : High pushout & torque-out resistance The clinching ring locks the displaced metal behind the tapered shank, ensuring high pushout resistance. High torque-out resistance is ensured when the knurled platform is embedded in the sheet metal. Distortion-free installation Proper installation forces will not distort or damage the threads in PEM nuts because the recommended shank length is always less than the minimum sheet thickness. Reverse side remains flush All clinching takes place on the fastener side of the sheet. The reverse side remains flush and smooth. Self-clinching Locknuts These locknuts (Type SLTM) are designed with a unique and economical TRI-DENT® locking feature, which meets demanding locking performance requirements. Thin Sheet Self-clinching Nuts These nuts (Type SMPSTM) feature a lower profile and can be mounted closer to the edge of a sheet than standard self-clinching nuts. Self-clinching nuts for stainless steel PEM 300° self-clinching nuts (Type SPTM) are especially designed for permanent installation into stainless steel sheets as thin as .030"/ 0.8 mm. Machined from a specialty stainless steel, these fasteners are then heat-treated to a hardness higher than most 300 Series stainless steels. This feature enables PEM 300 fasteners to be installed into stainless steel sheets, employing the same self-clinching principle which has proved successful over the years in thousands of applications.

...moreBe first to Rate

Rate ThisOpening Hours