Universal Gear Couplings

Universal Gear Couplings are designed to handle the misalignments of connected shafts. These couplings in an assembled condition are ready to take misalignment (see fig, 1,2 & 3)

...more

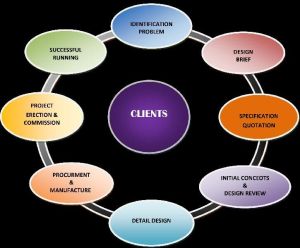

UGI Consultancy services

We extend consultancy services to our client for effective layout of plant. We provide the following services to our clients: Feasibility Study and Project Reports: We undertake the feasibility study, that is the preliminary study to determine the viability of a project.If the project for steel plant construction is feasible, we also prepare the project report in a structured and logical format. Detailed Engineering of project and Equipments: We offer detailed engineering which includes layout planning, cost control, designing of steel plants, commissioning of plant components and quality assurance. Equipment Designs and Production Drawings: Turnkey steel re-rolling plant has been involved in new equipment design and development of custom built plant and process.

...more

Tilting Table / Y Table

Reheating Furnace

MODERN SECTION MILL

Hot rolling mill for Long products, UGI Engineering has been manufacturing most modern Light, Medium & Large Section Mills of ferrous & non-ferrous Metals to minimize the operational costs, increase productivity and fuel & power efficiency and for reduction in environment pollution.

...more

UGI Mill Shears Machine

UGI Mill Shears & Saw Machine has made from EN-8 Steel fabricated stress relived body construction with control panel, starter, Automatic Operating System & Centralize Oil Lubrication System . UGI Engineering offers a full line of hot and cold shears necessary in a bar or rod mill for a wide variety of requirements, such as head tail cropping , dividing, sampling or scrapping, cutting-to-length. Sawing units are available for rails, medium-large sections, large bars, and special steel grades, where sawing is preferred over shearing.

...more

Heat Treatment

Heat treatment is carried out in the most modern plants and special heat treatment like Gas Carburizing, Nitriding, Induction hardening are also carried out. All forging are ultrasonically tested for internal defects and are normalized, annealed or stress relieved before further processing.

...more

Gear Coupling

The advantages of using Geared Coupling on all directly connected machinery is now recognized and appreciated by engineers and operating men. Gear couplings are intended to compensate for the usual and unavoidable errors in alignment and should allow free lateral flowto the connected shafts. Even when favourable conditions permit perfect alignment to the two Shafts, there is no assurance they will remain so, the vibrations, the sinking of foundation, wear of bearings and inaccuracies in machining are all common enemies to the safe and efficient operation of connected machinery.

...more

Cooling Beds

UGI Engineering cooling beds are designed using standard elements that can be combined in accordance with plant product mix requirements and production capacity. The design features cover a variety of applications : rounds from Ø 8 to 100 mm .

...more

alignment

Misalignment of machines connected by rigid couplings not only causes excessive wear of couplings and machine parts but also increase power consumption. When two out of line shafts are connected rigidly, severe bending stresses are set up in each shaft. For each revolution, the shaft passes through a complete cycle of tension and compression stresses and would be likely to fatigue the shaft material and considerable heat and damage the whole mechanism.

...more

Cooling Bed

Pinch Roll

Mill Stand

All mill stands are built heavy to with stand high rolling load. Roll necks are with antifriction bearings. Close control set up of screw down & axial shift of rolls are provided to prevent roll skewing during rolling. Finishing Mills are 4-High design to give 8 gage accuracy. Edging stands are provided for edge control.

...more

wire rod mill

Twin Channel

Roller Guides/Slitter Guides

crop shear

Tail breaker

Billet Charging Pusher

Discharging Ejector

Pinion Stand

Crank Shear

double helical gear box

Pinion Shafts

Be first to Rate

Rate This