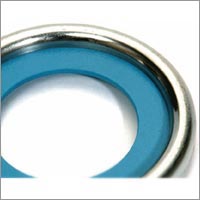

Industrial Ring Joint Gasket

200 Per Piece

100 Piece (MOQ)

Ring Joint Gaskets

Get Price Quote

We are well-reckoned Manufacturer, Exporter and Supplier of a wide range of Ring Joint Gaskets. The gaskets are suitable for high temperature and pressure industrial applications. We offer Ring Joint Gaskets in R, RX, BX styles and in oval/octagonal profiles. Our company fabricates them in compliance with specific tolerances as per API spec 6A and ASME B16. 20 standard (where applicable) on CNC machines. Buyers can purchase Ring Joint Gaskets form us at market lading prices. Our Ring Joint Gaskets are monogramed as per API- 6A (PSL4). Prime Feature : R – Type ( Oval and Actagonal ) : API R- Type Ring Joint Gaskets come in two basic types, an oval cross section and an octagonal cross section. These basic shapes are used in pressures up to 10,000 psi. The dimensions are standardized and require specially grooved flanges. The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 Micro inches and be free of objectionable ridges, tool or chatter marks. They seal by an initial line contact or a wedging action as the compressive forces are applied. The hardness of the ring should always be less than the hardness of the flanges. BX and RX Ring Gaskets : The BX ring gasket differs from the standard oval or octagonal shape in that it is square in cross section and tapers in each corner. BX can only be used in API 6BX flanges. RX ring gaskets are similar in shape to the standard octagonal ring joint gasket but their cross section is designed to take advantage of the contained fluid pressure is effecting a seal. Materials Standard: Soft iron, low carbon steel, alloy steels F5 and 410; stainless steels 304, 304L, 316, 316L, 321 and 347. Non-standard: high nickel alloys, super alloy steels and other stainless grades. Rubber coated ring joint gaskets - soft iron metal ring joint gaskets are coated with nitride rubber for testing wellhead assemblies and valves. Rings can be reused and do not damage flange grooves.

Best Deals from Ring Joint Gaskets

Ring Joint Gasket

Get Price Quote

Metallic Ring Joint Gaskets are suitable for high pressure and high temperature applications. The Ring Joint Gaskets are available in R, RX, BX styles and in oval/octagonal profiles. SEW manufacture Ring Joint Gasket in accordance with specific tolerances on CNC machines. These Ring Joint Gaskets fully comply with the ASME B16.20 standard and the API spec 6A requirements (where applicable). Prime Features R-type (oval & octagonal) solid sections to fit standard ring joint flanges with trapezoidal grooves Type RX and BX with complex beveled edge sections for wellhead pressure above 700 bars Combination Gaskets � Used where two flanges of different sizes are to be joined together Split Gaskets � Used where an API flanges is to be joined with a low pressure ANSI Flanges where a spiral wound gasket is used Special metal gaskets made to customer specifications Materials Standard : Soft iron, low carbon steel, Alloy steels F5 and 410: stainless steels 304, 304L, 316, 316L, 321 and 347 Non-standard : high nickel alloys, super alloy steels, and other stainless grades Rubber coated ring joint gaskets : soft iron metal ring joint gaskets are coated with nitrile rubber for testing wellhead assemblies and valves. Rings can be reused and do not damage flange grooves

D I PIPE JOINT RUBBER RING (GASCKET)

Get Price Quote

T Type Rubber Ring for Ductile Iron Pipe size: 80mm to 700mm Rubber type:SBR/EPDM/NBR/NR Application:Ductile Iron Pipe Joint Sealing Standard: IS 5382 Also available as per buyer's sample or drawing

Rubber Ring Joint Gasket

16 Per Piece

10000 Piece (MOQ)

Ring Joint Gasket

Get Price Quote

Ring Type Joint Gaskets

Get Price Quote

50000 Piece (MOQ)

Ring Joint Gaskets

Get Price Quote

Ring Type Joint Gasket

Get Price Quote

We are offering ring type joint gasket. Ring type joints are primarily used by the oil, gas, petrochemical and offshore industries, they are also commonly used on valve, pipe work assemblies and with some integrity vessel joints. Ring type are use to seal flanged connections subject to high pressures and temperatures. These precision made solid metal gaskets form a metal to metal seal with the flanges. The gasket cross-sections are designed to concentrate the bolt load over a small area to produce a high seating stress. The gasket metal should always be softer than the mating flanges. The high seating stress causes 'plastic-flow' of the gasket into the flange faces to create seal. The 'rx' and 'bx' gaskets are designed to be pressure activated by the sealed media which improves the efficency of the seal as the internal pressure of the system increases. 'r' series ring type joints can contain pressure up to 10,000 psi 'rx' and 'bx' series ring type joints can contain pressure up to 20,000 psi the gasket and flanges must be manufactured to precision dimensions, surface and hardness.

Ring Joint Gaskets

Get Price Quote

We have come up with the finest range of Ring Joint Gaskets for our clients. WFY RJ3200 is machined from solid metal in a variety of shapes and designed for high pressure, high temperature or highly corrosive applications by selecting the most suitable material and shape. Our Ring Joint Gasket is designed to withstand exceptionally high assembly loads over a small area, thus producing high seating stresses. Ring Joint Gaskets are obtained by mechanical working from forged or laminated metals. These Ring Joint Gaskets are employed in the production and refining process of oil and chemical industries. These gaskets are designed in oval/octagonal shapes confirming to R, Bx and Rx series of API STD 6A. Types 3300 PL Plain type RJG 3300 OV Oval type RJG 3300 OC Octagonal type RJG 3300 RX RX type RJG 3300 BX BX type RJG 3300 S Special type RJG Applications Steel Mining Petrochemical Refining Fertilizer industries

Ring Joint Gaskets

250 Per Unit

10 Piece (MOQ)

Ring Joint Gaskets

50 Per Piece

We are the main supplier of this product.

Rx Ring Joint Gasket

70 Per Kilogram

50 Kilogram (MOQ)

We are designated as a position of trustworthy suppliers involved in dealing with RX Ring Joint Gasket and offering the best deals. We ensure complete contentment to the clients by delivering the only flawless range of goods as we store the complete batch in our capacious warehousing unit that is well-structured and maintained. Features : Corrosion resistance, Durability, High strength, Superior finish.

PTFE Inserted Ring Type Joint Gasket

Get Price Quote

We are well-known Manufacturer, Exporter and Supplier of high quality PTFE Inserted Ring Type Joint Gaskets. With our team of qualified professionals, we fabricate premium Ring Type Joint Gaskets that are used to reduce turbulence as product flows through it. Our quality assurance team makes sure that optimum PTFE is inserted that can prevent the build up of debris in the annular space. Timely delivery and affordable prices are our priorities.

Ring Joint Gasket

Get Price Quote

Ring joint gaskets are manufactured in different solid metal types such as Soft iron/SS304/316/321 metals and similar other alloys. These ring joint gaskets are ideal for the industrial use due to their enhanced performance and reliable durability. These ring joint gaskets stop leakage that causes corrosion around manholes and hand holes in steam boilers, water heaters and air tanks.

Ring Joint Gaskets

Get Price Quote

We are one of the trusted Manufacturers and Exporters of Ring Joint Gaskets in the market. The Ring Joint Gaskets that we provide are made by using optimum quality raw material and have been always appreciated for their high quality. Ring Joint Gaskets are manufactured in accordance with API-6A, API-17D and ASME B16.20 specifications. We offer these Ring Joint Gaskets at the most affordable prices. Specifications : RTJ's have "R, RX and BX" numbers assigned to them for pipe size and pressure class identification.Stock materials include Soft Iron, Low Carbon Steel, F5, F11, F9, 304, 304L, 316, 316L, 321, 347, DUPLEX, Monel, NICKEL, 410, Inconel and Incoloy.

Ring Joint Gaskets

Get Price Quote

We have a well-maintained and spacious storage space and thus, we are flexible enough of meeting the urgent needs. Furthermore, we by no means go out of stock and thus we maintain year round accessibility of all the products. We meticulously pack the entire lot for ensuring safe and secure deliveries across the boundaries. Features : Longer service Supreme quality High accuracy

Ring Type Joint Gasket

Get Price Quote

Ring Type Joint Gasket

Get Price Quote

Octagonal Ring Joint Gasket

Get Price Quote

We have established ourselves as a renowned manufacturers and suppliers of a wide range of Octagonal Ring Joint Gasket. These Octagonal Ring Joint Gasket are divided into two principal categories that are Flat Gaskets and Ring-Joint Gaskets. The offered Octagonal Ring Joint Gasket are manufactured using metal or alloy without soft filler. Machined from solid metals in oval shape, these gaskets are designed for high pressure, temperature and highly corrosive applications by selecting. This product is customized as per the clients' requirements. Features: Lightweight Superior finish

BX Series Ring Joint Gasket

Get Price Quote

Style BX Gasket : BX pressure energized Ring Joint gaskets, manufactured in accordance with API 6A, are designed for use on pressurized systems up to 20,000 psi Style BX gasket design allows virtual face to face contact with the flange faces which in tur making the gasket fully trapped on both the inner and outer diameters. All BX Gaskets incorporate a pressure balance hole to ensure equalization of pressure which may be trapped in the grooves. One pressure passage hole required per ring on center line.

ring joints gaskets

Get Price Quote

ADFO Manufacturers and supplies a large variety of ring joint gaskets. The RTJ standard size gaskets are manufactured in accordance to API -6A and ASME B16.20 specifications. These Gaskets are manufactured in various types, comprising of R type (Oval & Octagonal), RX type, BX type, in Low Carbon Steel, Soft Iron, Stainless Steel (SS304L,SS316L, SS347). We are an API Monogram License (American Petroleum Institute) Holder, License No. 6A-1346 and this is punched on all the gaskets we supply.

Ring Joint Gasket

Get Price Quote

Ring Joint Gaskets

Get Price Quote

We present an incomprehensible range of Ring Joint Gaskets. Long life and efficacious performance is the features due to which these gaskets are high in demand globally. These ring joint gaskets are available in various sizes as per the requirements of our customers. Last but not the least, we also provide tailor-made services to our honored customers.

Ring Joint Gaskets

Get Price Quote

SEW manufacture the metallic Ring Joint Gaskets which are tested and bold to bear the high temperature and Intensive pressure both at the same time. Metalic Ring Joint Gaskets are having segmentation and available in R, RX, BX styles and patterns and oval/octagonal profiles as well. Our products are having specific and great value of tolerances on CNC machines. We desing and manufacture the Ring Joint Gaskets which are abide by the the API spec 6A and ASME B16.20 standard We are promising to deliver the units of materials with varity of standard and qualitative materials The units are manufactured in a variety of standard and special materials. Prime Features As per the customer specifications, special metal gasket are manufacture. Combination Gaskets – Used where two flanges of different sizes are to be joined together. R type (oval and octagonal) solid sections to fit standard ring joint flanges with trapezoidal grooves. Types RX and BX with complex beveled edge sections for wellhead pressures above 700 bars. Split Gaskets – Used where an API flange is to be joined with low pressure ANSI Flange where a spiral wound gasket is used. Materials Rubber coated ring joint gaskets – soft iron metal ring joint gaskets are coated with nitrile rubber for testing wellhead Standard: Soft iron, low carbon steel, alloy steels F5 and 410; stainless steels 304, 304L, 316, 316L, 321 and 347. assemblies and valves. Rings can be reused and do not damage flange grooves. Non-standard: high nickel alloys, super alloy steels and other stainless grades.

Ring Joint Gaskets

Get Price Quote

We manufacture Ring Joint Gaskets conforming to R series in Octagonal / Oval shape, Bx and Rx series of API std 6A and ASME B 16.20. They are used in the production and refining process pipelines of oil and Gas Industries.Made from solid metal types like : Soft Iron/LCS - Low Carbon Steel – Electroplated as per your specs zinc electroplated (By Default); Yellow Pacification; Cadamium Plated and Hot Dip Galvainsed. Stainless Steel AISI 304/316/321 Income and other Alloy grades.

Ring Joint Gaskets

Get Price Quote

Ring joint gaskets are produced from different solid metal types. They are used to stand high pressure and temperatures and they are employed where corrosive agents are present. These gaskets are obtained by mechanical working from forged or laminated metals in one single piece. They are employed in production and refining process of oil and chemical industries. ring joint gaskets are strictly manufactured to api-6aasme b16.2 specifications. ring joint gaskets shall be either octagonal or oval in cross section and identify by r, rx or bx number that relates to flange size (nps), pressure class and appropriate flange standards.

EP Gasket Rings

Get Price Quote

5000 Piece(s) (MOQ)

Stainless Steel Ring Joint Gasket

Get Price Quote

Ring Joint Gaskets

Get Price Quote