TYRE TRIMMING MACHINE

The machine is designed as a manipulation device for the flash trimming of radial truck tyres. It is configured as a double station unit facilitating trimming of two tyres simultaneously. Sufficient exterior and interior lighting is provided to facilitate exhaustive inspection of the tyres. This machine shall be suitable to carry out the trimming operation with the facility of variable Height and variable Tyre rotating Speed.

...more

TYRE INSPECTION MACHINE

The inspection spreaders have been designed to facilitate visual inspection of the inside and outside of tyres. Different automatic cycles can be programmed based on the number of revolutions the tyre will complete during the inspection and the travel of the spreading arms. CONTROLS The required machine is meant to facilitate easy and proper inspection of cured tyre. The logical operation will be controlled by relay logic. AC Motor of desired rating, which will have two speeds, will do the rotation of the tyre. The tyre would be rotated at such level to ascertain complete vision of inner side.

...more

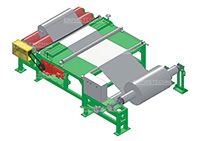

Tread Slitter Machine

The Tread Slitter Machine is designed to slit uncured rubber Tyre Treads longitudinally into smaller width strips. The machine mainly consists of Tread Transfer Unit, Tread Centering Assembly, Idler Roller Conveyor, Tread Slitting Unit with Drive, Tread Pressing Unit, Powerised Roller Conveyor and Control Panel.

...more

TREAD JAMMING MACHINE

The Tread Jamming Machine is designed to stitch the joint portion of the Green Tyre of different sizes. The machine mainly consists of a Stitcher Assembly, Electric Motor with Gear Box and sprockets.

...more

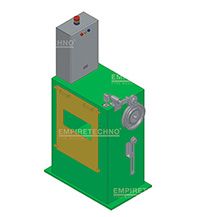

SPOT CURING MACHINE

Spot repairing machine is used to repair any type of spot that erupts while curing of the tyre. The machine has pneumatic operated heated platen which keeps the tyre hard-pressed for a set time. The machine is equipped with Temperature controller and timer making the machine more operator friendly.

...more

SIDEWALL WIND UP UNIT

Dual Wind Up Unit for CVT/PLT SidewallThe wind up is used for sidewall used for producing CVT & PLT sidewalls , Apex, and Rim strip. The unit includes all necessary mechanical parts, electrical drives and controls. The wind up unit is connected with existing Extruder line and synchronize with it, and this system can be operated automatically or manually. THE UNIT CONSISTS OF FOLLOWING-: CUTTER ARRANGEMENT An online cutter arrangement with a heated rotary knife shall be provided. Cartridge heaters shall be provided for heating the knife to a thermostatically controlled temperature of 120 degrees..Cutting will be done in respect to hardened anvil roller. MATERIAL WIDTH MEASURING DEVICE A special CCD array camera to be used for detecting the width of the material. MARKING SYSTEM The device is to be pneumatically activated when the measured profile will be out of tolerance. FIXED OVERHEAD CONVEYOR The fixed overhead conveyor will feed the material to wind up station 1.There will be a dancer unit on the exit of this conveyor which will ensure that material is winding in uniform tension. WIND UP STATION-1 Wind up station suitable for Sidewall cassette will be provided with provisions of E+L make liner centering system & tension control system for liner. SHUTTLE OVERHEAD CONVEYOR After Wind up station-1 is full, the pneumatically operated shuttle overhead conveyor will move forwards towards fixed overhead conveyor and transport the material to wind up station -2. WIND UP STATION-2 Wind up station suitable for Sidewall cassette will be provided with provisions of E+L make liner centering system & tension control system for liner.

...more

SHEET FEEDER machine

This machine is basically a hydraulic press of closed H frame with single daylight and steam heating platen. The bottom platen is fixed to the base frame & top platen is moved by means of hydraulic cylinders. On the front and rear sides of the press, fabric clamping mechanism is provided for holding the fabric while splicing process. Splicing is done at a temperature of 185 deg C for a cycle time of 50 to 60 seconds.

...more

OVERHEAD FEED CONVEYORS

With over four decades of experience, Empire Techno Engineers Private Limited has been a pioneer in the field of rubber machinery manufacturing Overhead Feed Conveyors and has a long list of satisfied client who have also proven to be our patron for many years.

...more

LINER REROLLING MACHINE

All Tyre Companies requires to make perfect winding of Liner Rolls before processing it for tire building. We are most renowned manufacturer of Liner Fabric Rewinding Machine and Liner Fabric Re-Rolling Machine. The machine is designed for 72” liner in such a way that liner winding will be perfectly centre and tension free. THE MACHINE Let off unit with brake. Table for liner visual inspection Auto centering system Wind up system

...more

LINEAR RE ROLLING MACHINE

The cassette undergoes winding & unwinding many times within plant operations. During frequent winding or unwinding, the liner gets dirty, form wrinkles, gets loose and de centered. This unit has been designed to reroll liner from liner roll to the product roll, and then vice versa to remove wrinkles, creases, and cleans the liner by brushing and removing dust from liner. SCOPE OF SUPPLY REROLLING STATION Wind Up station is designed to suit any particular cassettes for rerolling operation. Each Roll (i.e. Stock Roll and Liner roll is driven by an AC Variable speed Geared Motor) EDGE GUIDING Electro Electronic edge guiding system of E+L Make (For guiding the Liner on way back from Stock roll to Liner roll) WEB TENSION A pair of load cells is used to give feedback to the tensioning system which ensures the liner is winding in uniform tension. CONTROLS A dedicated electrical panel consisting of PLC, VFD’s and switchgears. SCRUBBER ROLL Scrubbing/ Brushing – To clean the liner SPREADER ROLL/BOW ROLL To remove wrinkles and creases.

...more

INNER LINER WIND UP SYSTEM

The dual inner liner wind up station for calendar line is used for automatic winding up of a sheet of calendered liner in CAPTIVE ( Dedicated) and NON CAPTIVE ( Drop in Type) cassettes. These dual wind up units are retrofitted with the existing calendar line running up to 30 mpm speed. Wind up station is designed for stretch free / wrinkle free operation and the product is centrally wound in the liners with uniform tension. The unit includes all necessary mechanical parts, electrical drives, pneumatics and controls. SCOPE OF SUPPLY Inlet conveyor Online Cutter Wind up station 1 Moveable conveyor Wind up station 2 FEATURES Both Wind up station fully equipped with Liner centering system. Controls are designed to run in tandem with our existing calendar line. Necessary provision is given to run the machine in Manual / Auto mode and there should be a provision to run in Forward / reverse mode. Each wind up unit is synchronized with the calender line so that there is no pull or dimensional changes to the end product. Final product is centered within +/- 2 mm in the Liner and the liner will be perfectly centered in the cassette.

...more

GREEN TYRE AWLING MACHINE

An apparatus for automatically awling tires to permit easy escape of trapped gases which may have been enclosed or developed interiorly of the casing during manufacture of green tyre.

...more

EDGE GUMMING MACHINE

The edge gumming machine is designed to assemble edge strips on both sides of the breaker material. This unit basically consists of the following parts: Strip Let Off – 2 Nos Strip Applicator Assy- 2 Nos Liner Poly Winder Assy – 1 Nos

...more

Compound Slitter machine

Compound Slitter machine is used for slitting compound sheet coming from batch off unit. There is also provision for-:1. Cut width adjustment on Cutter assembly2. Laser Beam Sensors to detect human hands/fingers around Cutter assembly

...more

Chafer Slitter Surface Winding Machine

Specialities : Highly precision,Simple cutter arrangement,Easy operation

Chafer Slitter machine

Chafer Slitter machine is used to Slit Fabric/ Nylon coated cross woven at the set width and rewound on spoolers/shell in surface winding, according to product thickness, on each spooler/Shell. It is aimed to feed tire building machines/Inner linner machine with minimum down time. This cut material represents the joint less chaffer which is oblique in modern tire design. Hence, the correct preparation and quality has distinct influence on the performance of tires. This machine have arrangement to run both Automatic & Manual Mode. The Loading/ Unloading of material are manual. The slitting performed on this machine is by means of positively driven toothed rotary cutter or Crush cutter. PRODUCT TYPES Chafer/Fabric Cross Woven FEATURES State of the art design Highly precision material centering system before material enters winding station Complete PLC control and touch panel for easy operation of machine Provision for liner feeding on each spool/shell with independent pneumatic brake on liner roll to maintain uniform tension Simple cutter arrangement to set at desired cut width Feeding of material manually at adequate working height.

...more

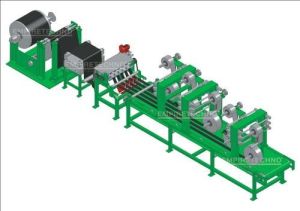

CAP STRIP SLITTER Machine

It features slitting cap material which is coated with rubber into 6 or 8 or 12 (depends on customer’s requests) smaller strip belts in a fixed width. Cap Strip Slitter can be used to slit Cap Ply in to equal no of strips which further spiral wind on 8-16 wind up stations . Each Wind up station having provision for PVC shell and each PVC shell having its own traverse unit. This machine is to support high performance tire faclilities for production levels from 5000 tires/day to 12000 tires/day FEATURES Double unwinder for rubberized material with 0 degree angle Stand alone splicing station Wind up strips from 8mm up to 25 mm Max Line speed- 50 m/min

...more

CALENDAR WIDTH SLITTER MACHINE

CALENDAR WIDTH SLITTER FOR CAP PLY & EDGE GUM MATERIAL TECHNICAL SPECIFICATION Between calendaring machines and tire building machines, Slitting is a critical aspect of product quality and process reliability. Our slitter are precise calendar width slitters to convert calendar rolls/ large rolls coming from calendaring machines and textile based products into smaller rolls of min 30 mm width. PRODUCT TYPES Calendered Textile Gum Edge With PVC Liner Calendered Bias Textile Cap Ply FEATURES State of the art design 2 Types of slitting in same machine (crush cutter & floating cutter) Independent tensioning systems on each winding shaft Highly precision material centering system before material enters winding station Complete PLC control and touch panel for easy operation of machine Provision for liner rewinding station Splicing station Easy cutter arrangement to set at desired cut width Centre winding- winding of the spools happen axially Winding is performed on shafts received in safety bearings/clutches installed on both sides of machine Trim poly winding arrangement at wind up unit (air motor ) Gripping stand for unloading of winded material for operator convenience

...more

BREAKER WIND UP SYSTEM

The dual breaker wind up station for wire/steel cord bias cutter is used for automatic winding up of breaker in CAPTIVE (Dedicated) and NON CAPTIVE (Drop in Type) cassettes. These dual wind up units are retrofitted with wire bias cutter. The start/stop of the wind up unit is controlled through loop sensors installed in a pit at starting of wind up unit. SCOPE OF SUPPLY Inlet conveyor Cutter – Rotary knife on Inlet conveyor Wind up station 1 Moveable conveyor Wind up station 2 FEATURES Controls are designed to run in tandem with existing wire/steel cord bias cutter. Necessary provision is given to run the machine in Manual / Auto mode and there should be a provision to run in Forward / reverse mode. Each wind up unit is synchronized with the loop sensors so that there is no pull or dimensional changes to the end product. Final product is centered within +/- 2 mm in the Liner and the liner should be perfectly centered in the cassette.

...more

BEAD FLIPPING MACHINE

This is a small unit for application of bead flipping in cold condition over rectangular beads ranging from 12” to 16”(PCR) or 17” to 34”(Tractor Size) bead diameters. After fillering the next step is flipping on the same bead , now the small ply covering will be done on the bead out side to cover up the filler.The entire operation controlled by the bead and presses the foot switch to allow the bead to rotate and to bring manually through various mechanical arrangement operated through different pneumatic cylinders.

...more

BEAD FILLERING MACHINE

This is a small unit for application of bead filler in cold condition over rectangular beads ranging from 12” to 16”(PCR) or 17” to 34”(Tractor Size) bead diameters. The entire operation is controlled by the bead and presses the foot switch to allow the bead to rotate and to bring manually through various mechanical arrangement operated through different pneumatic cylinders.

...moreBe first to Rate

Rate ThisOpening Hours