Floating Head Heat Exchanger

Get Price Quote

1 Piece (MOQ)

Air Cooled Chiller Condenser

50,000 - 100,000 Per Piece

1 Piece (MOQ)

Best Deals from Heat Exchangers

Compressor Intercooler

Get Price Quote

1 Piece (MOQ)

Stainless Steel Heat Exchanger

Get Price Quote

Heat Exchangers

Get Price Quote

We are one of the manufacturer, exporter and trader of Heat Exchanger for Chemical Industry. These offered products are highly appreciated by client's in the market. These products are manufactured by using premium grade Steel that is appreciated for its corrosion resistance.

Waste Water Recovery Systems

Get Price Quote

1 Piece (MOQ)

Water Cooling Tower

25,000 Per piece

5 piece (MOQ)

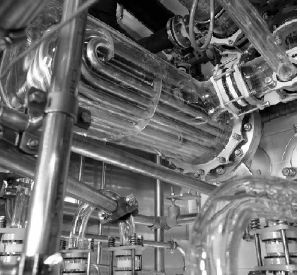

COMPRESSOR AFTERCOOLER

Get Price Quote

We offer Aftercoolers that are fabricated using the latest production techniques. Our aftercoolers are specialized heat exchangers that are used in multi-stage compressor systems to cool the pressurized air or gas. Aftercoolersare designed for direct / floor mounting arrangement. Moreover, compressed Aftercooler are available in standard horizontal / vertical models, with or without built in Moisture Separators. We can supply aftercoolers suitable for entire range of compressors manufactured by Ingersoll Rand, Kirloskar, Joy Cooper, Khosla, Chicago Pneumatic, Atlas Copco. Our After Coolers are directly inter-changeable with the OEM ones.

Cooling Tower Sprinkler

Get Price Quote

100 Piece (MOQ)

Frp Cooling Tower

80,000 Per Piece

1 Piece (MOQ)

Aluminum Air Cooled Heat Exchanger

35,000 Per Unit

1 Unit (MOQ)

Iepl Condensate Recovery System

100,000 - 200,000 Per piece

Mechanical condenasate pumpthere are condensate recovery unit or power pressure pump use for transfer steamcondensate from plant to boiler feed water tank with help of motive steam or air.working of principal condensate recovery pump or power pressure pump: there are two stage of pump working 1) filling mode: condensate from process will be collected in pump receiver tank due togravity it will open check valve and start filling pumping tank. By this time motive inletis closed and vent outlet is open so there is no back pressure. This will lead level low tohigh.2) pumping mode: as the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time delivery check valve will be open and inlet check valve shut off.when low level reached automatically repeat the cycle. I.e. Shut off the motive valveand open the exhaust.in comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also ss float puncture with time due to constant expansion and contraction due to temperature variation.while in our system "applied for patent" we avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle.features1. Pump total material are ss 304 material so life is long life.2. Float material is special materials so it will not punctured.3. No moving part assured zero maintenance.4. Suitable for high temp. Application. No cavitations problem5. Can be operated on compressed air.6. Various sizes for different capacities.(max. Cap.12,000 kg/hr)

Shell and Tube Heat Exchanger

200,000 Per Piece

1 Piece(s) (MOQ)

charam techno chemical & equipments (p) ltd. Is listed among the prominent heat exchanger manufacturers in india. The world class shell & tube heat exchanger manufactured by us, can be used for con. Sulphuric acid cooling in the chlorine gas compression system. The heat exchanger is designed according to tema class b & c standard to meet the customer requirements. Our product is tested hydraulically & pneumatically as per standards for the strong structure with special emphasis on the welding quality. The materials used are carbon steel, ss 304, ss 316 & titanium.

Crimped finned tubes

100 - 400 Per Piece

50 Piece (MOQ)

Glass Heat Exchanger

Get Price Quote

10 Piece (MOQ)

Optimum Solution for every requirement A range of designs available & in modular construction Wide range of duties namely ; Condensation, Cooling, Heating, Boiling & Evaporation Material of construction comprise of a combination of highly corrosion resistant materials including Borosilicate 3.3 Glass , SiC, Fluoropolymers (PTFE, PFA, FEP, PP) & Exotic metals (Ta, Nb, Ti, Zr, etc) Fabricated with all major internationally prevalent buttress designs and having a very high reliability of the strong and high-duty coupling system used for all components Non-standard & special custom designed can also be supplied to special order.

horizontal accumulator

Get Price Quote

We bring forth a comprehensive assortment of Horizontal Accumulator that is developed for wire storage during reel change on payoff or take-up. Use of a horizontal accumulator eliminates line speed reduction, gives continuous operation resulting in less man power and less scrap generation. Our range of Horizontal Accumulator is high on demand in the market and can be availed at the most competitive prices. Appreciated For : Continuous productionZero maintenanceCorrosion resistanceExcellent functionalityHigh durability

STAINLESS STEEL VESSEL GAS COOLER

165,000 Per piece

A vessel gas cooler, specifically a shell and tube gas cooler, is a type of heat exchanger used to cool gases or vapors in industrial processes. It consists of a cylindrical shell with a bundle of tubes running through it. The gas to be cooled flows through the tubes, while the cooling medium, typically water or a refrigerant, circulates around the tubes within the shell.The gas enters the cooler through an inlet connection and passes over the external surface of the tubes. As it comes into contact with the cooler tubes, heat is transferred from the gas to the cooling medium. This causes the gas to cool down and potentially condense.The cooling medium, circulating inside the shell, absorbs the heat from the gas and exits the cooler through an outlet connection. It may be cooled by external means, such as a cooling tower or refrigeration system, before being recirculated back into the shell.The design of the shell and tube gas cooler allows for efficient heat transfer due to the large surface area provided by the tube bundle. The tube bundle is typically removable, allowing for easy cleaning and maintenance.Shell and tube gas coolers are widely used in various industries, including oil and gas, petrochemical, chemical processing, and power generation. They are employed in applications such as gas compression, gas separation, vapor recovery, and gas conditioning.These coolers can be customized to meet specific requirements, including variations in shell and tube materials, tube arrangement, and overall dimensions. It is important to consider factors such as gas composition, pressure, temperature, and desired cooling capacity when selecting a shell and tube gas cooler for a particular application.

Industrial Heat Exchanger

Get Price Quote

When it comes to Industrial Heat Exchanger, the name of our company is highly revered as pioneering Exporter, Manufacturer and Supplier from Mumbai. We fabricate this Heat Exchanger using latest technology in compliance with international standard. Our high performance based Industrial Heat Exchangers find application in areas of air conditioning. Our finest quality Heat Exchanger is able to provide exceptional heating capacity and supreme durability. We offer our Heat Exchanger to almost anywhere at the best possible rates within stipulated time frame.

aluminum heat exchangers

Get Price Quote

We are leading Manufacturer, Supplier and Exporter of Rice Mill heat exchangers, chennai, India that is manufactured by using high grade raw material as per the client’s requirements. Our range is available in various sizes & specifications and is widely used in different rice mills. These are appreciated in the worldwide market and are offered at the competitive prices.

FRP Dry Cooling Tower

32,000 Per Piece

1 Piece (MOQ)