Solvent Extraction Plant

Get Price Quote

solvent extraction unit

Get Price Quote

We are recognized as the leading herbal extract machine manufacturer from India. Used for the extraction of oleoresin and concentrate from various herbs and spices, this oil extraction plant is widely demanded by our customers. In addition to this, this herbal extract machine is also available in varied specifications and can also be customized as per the demands of our customers. Durability, low maintenance and minimal flow resistance are the features of Solvent Extraction Unit provided by us. This can be obtained at the most competent prices. The main attributes of our solvent extraction unit include : Low flow resistance Very durable Require low maintenance Established and time tested engineering No marginal deviations in gravities Ensured complete recovery of product

Best Deals from Solvent Extraction Plant

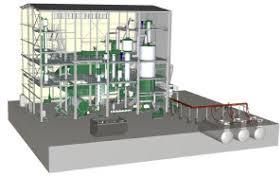

Solvent Extraction Plant

10,000,000 Per Piece

1 Piece (MOQ)

Features: Low maintenance Minimum flow resistance Longer functional life Other Details: Extractor speed is controlled by the frequency controller system with a provision for checking the load on the extractor accurately this provides information well in advance about the extractor band conveyor safety The desolventizer toaster is of a very modern design which is energy efficient with 99.9% desolventizing features by a counter current vapor path in the true sense This system achieves far better color and texture of the Soya meal by our unique design Our low temperature distillation system operates the final oil at a temperature much less than others, thus enhancing the bleachability properties of the oil, with less red units in the oil We provide the latest process instrumentation in the plant to maintain the process parameters Operator friendly plant for ease of operations and delivering the quality and quantity output Minimum quantity of effluent generation Plants for processing a wide variety of oil seeds and oil cakes Robust plant and machinery with bought out items from standard suppliers Unmatched quality performance

Solvent Extraction Plant

Get Price Quote

Liquid extraction, sometimes called solvent extraction, it the separation of a liquid of a liquid solution by contact with another insoluble liquid. The Fully Automatic Solvent Extraction Plant described is for semi-batch operation. The liquid to be extracted is poured into extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condensed, the condensed liquid in a reflux divider and passing through pipe work to the extraction vessel. The pipe work incorporates valve in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative density of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is reputed until the extraction is complete. The extraction vessel is than drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained from their respective vessel. The Solvent Extraction Plant is available in vessel size upto 500 Ltr. and is suitable for operation under atmosphere pressure and vacuume. Today, we have carved a niche as one of the prime Modular Solvent Extraction Plant Exporters based in India.

Spent Earth Extraction Plants

25,000,000 Per Piece

Nicotine Extraction Plant

550,000 Per piece

1 Piece (MOQ)

Nicotine is a natural product of tobacco, occurring within the leaves of nicotiana tabacum during a range of 0.5 to 7.5% counting on variety. Nicotine is additionally found within the leaves of wild tobacco, in amounts of 2–14%; in Duboisia hopwoodii and in Asclepias syriaca.

Effluent Treatment Plant for Solvent Extraction

475,000 Per piece

1 piece (MOQ)

Reaction Extraction Unit

140,000 Per unit

This is a general purpose batch reaction distillation unit to be operated at atmospheric pressure or vacuum. While heating bath heats and evaporates the contents of the vessel, the stirrer agitates to avoid heat spots. Vapors enter the condenser through reflux divider and get condensed. The condensate is then cooled by a product cooler and collected into a receiver. The unit is complete with a spherical vessel, drain valve, heating bath, thermometer pocket, liquid additional vessel, stirring assembly with drive, coil condenser, reflux divider, product cooler and receiver with drain valve.

Solvent Extraction Plant

Get Price Quote

We provide Solvent Extraction Plant at Big Byte Innovations Pvt Ltd, which is also recognised as liquid harvesting. Solvent extraction is a technique of extracting various components from one liquid phase into another liquid phase. It can also be defined as a method of separating elements from a combination by dissolving them in a solution. Solvent Extraction Plant from Solvent Extraction Plant Exporters employs materials that are chemically distinct and can thermodynamically decompose at higher temperatures. It is appropriate for materials with similar vapour pressures. The product could indeed be easily extracted from the mother solution without the use of any moving parts within the system. The technique is suited for materials that may cause problems due to a minor difference in specific gravity. Our manufactured goods are made from the highest quality raw materials, which guarantees the product's sturdiness. Top-notch designs, better rates, and delivery speed are the three key factors in our customized designs that are the main aspects of our achievement. Our professionals use cutting-edge technology and machines to manufacture these products in accordance with international quality standards and guidelines. Furthermore, they help to reduce the dangers of environmental damage and are thus environmentally friendly. The plants are ergonomically correct, energy-efficient, coherent in output quantity and quality, user-friendly, and produce less affluent

Solvent Extraction Plant

Get Price Quote

Mechanical method is the combo of high pressure, high temperature, & high moisture, which causes color fixation, oxidation, and hydrolysis. Some seeds like rice bran & soya cannot be handled by the expellers. Continuous solvent extraction plant does not cause any alteration to the property of oil and recovers it with the characteristics as where present in the raw material and can handle all materials. CAPACITY – 50 TPD TO 2000 TPD SHREEJI continuous solvent extraction plant consists of Seed preparatory section Solvent extraction section Distillation section Meal de-solventising section Recuperation section Meal conditioning section Preparation is the process of properly preparing seeds for extraction of oil either by solvent or mechanical method. While a particular seed may contain from 20 % – 50 % oil, the oil is tightly bound within the cell & mechanical action must be taken to either forcefully remove the oil or to make the oil accessible to subsequent solvent extraction. The unit operations typically involved are scaling, cleaning, cracking, conditioning (or cooking) & flaking. Depending on process & oilseed in question, process drying and hulling may be employed, as May expander and collect dryer/coolers. Welcome to the SHREEJIs Solvent Extraction Process The main objective of the extraction process is to reduce oil contain in oilseed to the minimum possible level. The chain conveyor from preparatory transfers the prepared material to the Rotary Airlock Feeder, which further drops it to the feeding hopper. Rotary airlock feeder ensures the effective vapor seal also regulates the feed. Hopper is provided with the special flameproof level switches for the indication of high and low level. So as to enable to generate audio signal in the situation of high level, for preparatory operator to take corrective actions. SHREEJIs Extractor is a mild steel construction rectangular vessel, installed horizontally. Pretreated material from preparatory moves on the specially designed articulated band conveyor inside the extractor. Band conveyor speed is adjusted according to the process demand. Band conveyor insures the continuous travelling of the feed material from feed end to the final end with determined speed, pre-calculated bed height and under the continuous solvent spray. Bed of the feed material on band conveyor is adjusted by adjustable damper. Band conveyor cleaning is accomplished by high pressure jet spray of fresh solvent on to the return of band conveyor at discharge end which ensures perfect cleaning of mesh and completely eliminates the possibilities of mash Choking & channeling. SHREEJIs specially designed spray breakers ensures the uniform distribution of solvent over the entire width of moving bed. Fresh solvent is admitted into the extractor near the discharge end of the moving bed of the material and the full miscella is recovered from the initial stage, thus ensures the perfect counter current flow of the material and the solvent. The miscella circulates in a closed circuit in each of the successive section by overflowing from each hopper. So in each section there is equilibrium between the oil extracted from the seed in corresponding section and the difference in oil content of solvent Overflowing the preceding hopper together with the solvent overflowing the following section. Special features of SHREEJIs Economizers Reduces the steam consumption. Increases the capacity of distillation Section increases the capacity of condensing section. The miscella from the tank is pumped through the vapor economizer, to the first evaporator. The economizer unit is specially designed in order to effectively utilize the heat of vapors emerging from the desolventizer toaster. The concentrated miscella thus obtained from the economizer unit is rapidly heated in the first evaporator by means of low pressure steam and enters into the flasher, where solvent vapors are flashed off. The oil rich miscella thus obtained is charged into the second evaporator & stripper. The flashed of solvent vapors are condensed into the condensers & liquid solvent is re-circulated back to the process through solvent water separator. Distillation system operates under high vacuum & lower temperatures & short distillation period ensures good quality of oil. Furthermore the distillation system is coupled with a final drying of oil in final oil heater, which results in production of oil with exceptionally low volatiles in it. Plants Section Biodiesel Extraction Plant Cattle Feed Manufacturing Plant Solvent Extraction Plant Get a Quote Head Office 11349/3A, St. No. 3, Partap Nagar,Industrial Area-B Ludhiana-141003. (INDIA). Manufacturing Unit 1 11460/1, St. No. 4, Partap Nagar,Industrial Area-B Ludhiana-141003. Manufacturing Unit 2 Dehlon Sahnewal Road,Teh.Dehlon Ludhiana-141206. Call Us +(91)-98142-22963, 99150-90111 Fax +(91)-(161)-2535575 Share Us Send Mail info@shreejiexpeller.com About Us Company Profile Weaving History Core Values Vision & Mission CSR & Guiding Principles Products Oil expellers oil presses Seed Preparatory Section Steam Generation / Boiler Spare Parts Plant Automation Section Cooking Oil Refinery Plant Biodiesel Extraction Plant Cattle Feed Manufacturing Plant Solvent Extraction Plant Oil Seeds Applications Cashew Shell Process Castor Coca Beans Copra Cotton Seed Ground Nut Jatropha Mustard Palm kernel SafFlower SHEANUT Soyabean Sunflower Infrastructure FABRICATION SHOP ASSEMBLY SHOP MACHINE SHOP PACKING AND DISPATCH Showcase Video Gallery Photo Gallery Copyright © Shreeji Expeller Industries - All Rights Reserved.

Continuous Solvent Extraction Plant

Get Price Quote

Solvent Extraction Plant

Get Price Quote

Solvent Extraction Plant

Get Price Quote

The purpose of preparation is to modify the seed into a shape that is suitable for fast and effective extraction by mechanical pressing or by solvent extraction. It is a succession of several of the following processes: seed Dehulling, to increase the protein content of the de-oiled meal, Cracking, to reduce the particle size of the seeds, Cooking, to reduce the viscosity of the oil and adjust the moisture content, Flaking, to rupture the cell structure of the broken seeds, and sometimes Expanding, to enhance extraction parameters.Extraction The seed, having been properly prepared, is separated into a crude oil fraction and a protein meal fraction by solvent extraction. The extractor utilizes a countercurrent, multi-stage washing with commercial hexane solvent to enable a reasonable quantity of solvent to extract a maximum quantity of oil. After washing, the solventladen meal drains by gravity and then discharges to meal desolventising. After washing, the oil/solvent mixture, commonly referred to as “miscella”, discharges to distillation.According to your specific needs, UB Projects provides a complete range of extractors.

Sal Plant

30 - 50 Per Piece

Solvent Extraction Plant

8,500,000 - 20,000,000 Per Plant

Solvent Extraction Plant

Get Price Quote

Solvent Extraction Plant that we offer is also known as liquid-liquid extraction. Solvent extraction is a method by which different components are extracted from one liquid phase into liquid phase. It can also be said as a process to separate components from the mixture by dissolving it in a solution. Solvent Extraction Plant makes use of such materials that are different chemically and can thermally decompose at higher temperatures. It is suitable for such materials that have same vapor pressures. The product can be easily recovered from the mother liquor without making use of any moving components inside the system. The method is ideal for those materials that can possibly create problems owing to their marginal difference in the specific gravity. Our Solvent Extraction Plant works upon the super class of solvent extraction theory. Also, we provide organic solvent extraction equipment. Featurers Of Solvent Extraction : Most Widespread Technique Speedy Latest Design Good Output Easy Handling Multipurpose Our manufactured products are made up of finest quality of raw materials due to which it ensures durability in the product nature. There are mainly three factors in our designed products which are the main keys of our success and these are quality designs, competitive price and timely delivery. We Have Cover Following Markets : USA : Montana, Florida, New-Jersey, Alaska-Nevada, New-Mexico, South-Dakota, Texas,etc. Middle East : Yemen, Syria, Arabia, Oman, Israel, Kuwait, Jordan, Saudi, Egypt, Cyprus,etc. Europe : Malta, Austria, Italy, Albania, Finland, Croatia, Andorra, Sweden, Poland, Monaco,etc. Others : Bhutan, Nepal, Pakistan, China, Myanmar, Maldives, Bangladesh,etc Indian Areas : Orissa, Bihar, Rajasthan, West-Bengal, Andhra-Pradesh, Punjab, Assam, Gujarat, Himachal-Pradesh, Karnataka, Mumbai, Haryana, Madhya-Pradesh, Delhi, etc.

Solvent Extraction Plant

Get Price Quote

We have Solvent Extraction Plant. MUEZ-HEST Solvent Extraction Plants square measure used for extraction of oil from oil bearing seeds and cakes like Rice Bran flavorer, Sunflower, Soyabean, Mustard Cake, Ground nut Cake, Neem Cake, Mahuwa Cake, helianthus Cake and different oil seeds and cake.We square measure specialised within the manufacture of superior quality Solvent Extraction Plant for petroleum refinery trade. Our advanced in-house unit assists within the planning & development of high performance Solvent Extraction Plant at competitive costs.Solvent Extraction plants square measure designed to extract oilthumb(27) directly from helianthus seeds, peanuts, cotton seed, nut, canola, copra, castor and kind of different materials. Solvent extraction consists of 4 main operations, • Extraction of oil from oil bearing seeds cakes. • De- solventising of de-oiled seeds cake. • Distillation, to separate the solvent from the Miscella. • Recover the solvent for apply. Salient Features: • Continuous operation. • Lower Solvent Losses. • Low sediment within the final oil. • Long Extraction time making certain low rock oil. • Simple, rugged style for low maintenance and reliable operator. • simple to move and install.

solvent plant machinery

Get Price Quote

Solvent Extraction is the process of extracting oil from oil-bearing materials by one way or another of Solvent. High temperature and high pressure process causes the oxidation of oil. Solvent Extraction is the advance process that is performed under very low temperature and vacuum to get the highest quality of oil. Solvent plants are used to extract oil directly from sunflower seeds, palm kernel, peanuts, copra, cottonseed, canola, castor and other materials.

Solvent Extraction Plant

Get Price Quote

The purpose of solvent extraction is to remove most of the oil contained in a seed. The purpose of solvent extraction is to remove most of the oil contained in a seed. Extraction is conducted on prepared seeds or, generally in the case of high oil content seeds, the cakes obtained by the pre-pressing. Solvent Extraction consists of a sequence of five operations, i.e. : Preparation of Seeds for Extraction which includes pre pressing for high oil content seeds. Extraction of oil from the prepared material with the aid of food grade solvent. Desolventising-toasting of the de-oiled seed /meal- often combined with drying and cooling of the said meal. Distillation, to remove the solvent from the extracted oil. Recovery of solvent, which is reused again and again at extractor level. Veendeep supplies the most advance,high performance Solvent Extraction plants which are able to process seeds like soyabeans,sunflower,cotton seeds,rapeseeds and floury material like rice bran.

Rice Bran Solvent Extraction Plant

Get Price Quote

Continuous solvent extraction plant of rice bran processing capacity 170 MTDay, manufactured by Agrochem Engineers, Tumkur, Karnataka, in the year 2005. Plant consisting preparatory section, main plant, dob section, storage section and utilities like cooling tower, weighbridge and ETP. Plant is in excellent condition. Details of some of major equipment are Preparatory section - Pelletizer 2 nos. 80mtday-each, cooker 200mt, siever 300 mt