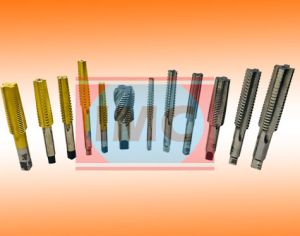

Hand Taps

Get Price Quote

Hand taps are for general purpose applications such as production tapping or hand tapping operations. Taper, plug and bottoming styles provide versatility in tough materials, blind and through holes. As to general physical dimensions, spiral point taps are identical with the standard hand tap.

Hand Taps-BSCy Form

Get Price Quote

we are offering Hand Taps-BSCy Form.

Best Deals from Bathroom Fittings

HSS Spiral Pointed Tap

375 Per Piece

25 Piece (MOQ)

Threading Taps

Get Price Quote

IMC Threading taps are specially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of the rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface that functions like a nut. Machine Tapping The internal Threading Machine is used a tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps are offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads, etc. Industrial Machinery Corporation will also offer the benefit of customization

THREADING TOOLS TAPS, THREAD TAPS, THREADING TAP

Get Price Quote

IMC Threading taps are especially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or are drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as for bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface which functions like a nut. Machine Tapping Internal Threading Machine is used tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc. Industrial Machinery Corporation will also offer the benefit of customization.

HSS Threading Tap

Get Price Quote

Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps: Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables

Roll Forming Taps

620 Per Piece

HSS Threading Tap

Get Price Quote

FEATURESThread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPTMaterial : Carbon Steel, HSSIncludes : Wooden Case, Taps, DiesType : Tap & DieSpecial Taps:Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special.material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding.There are essentially four qualities in successfully designing and manufacturing a tap.theoretical knowledge and practical experience are intrinsic in this process.size form geometry texture or finishBase material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

HSS Threading Taps

Get Price Quote

Our organization assures distribution of wholesale as well as retail consignments of the goods as per the jointly decided period. We have our own storage unit wherein we keep a large stock for meeting urgent and massive requirements of the clients. Laced with modern amenities, this unit keeps the lot free from the damaging factors. Features : Thread - TPI or Pitch - 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material - Carbon Steel, HSS Includes - Wooden Case, Taps, Dies Type - Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

H.S.S Ground Thread Taps

Get Price Quote

Tap Wrench Round Die Handle

Get Price Quote

threading tap

Get Price Quote

Shower Sliding Set

Get Price Quote

Assembly parts made with genuine stainless SS 304 grade for SDR-301 set. Height adjustable as per acutal site conditions. Complete set of rollers and track. Made up of Genuine SS-304 material.

Lambretta Auxiliary Fuel Gas Spare Tank On-Off Tap 300ml

10 Per Piece

As Per Order Piece (MOQ)

HSS Threading Taps

Get Price Quote

HSS Threading Taps, Cutting Tools, Bottom Cup, Swivel Coupler

high speed steel threading taps

Get Price Quote

high speed steel threading taps, Carbide Insert Tool Holders

Faucets

Get Price Quote

We are offering faucets.

Threading Taps

Get Price Quote

Threading Taps, Bi Metal Bandsaw Blades, Hacksaw Blades

Threading Taps

Get Price Quote

Threading Taps, Automotive Parts, Bicycle, brake sets, bicycle tools

Threading Taps

Get Price Quote

We are offering threading taps.