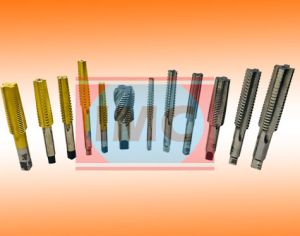

H.S.S Threading Tap

Get Price Quote

H.S.S Threading Tap Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding, Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above.

HSS Threading Taps

Get Price Quote

We offer superior quality HSS Threading Taps that are commonly used in various industries. To match the different needs of the clients, we provide HSS Ground Thread Taps in various sizes. High durability, excellent performance and low maintenance are some of the salient features of our High Speed Steel Thread Taps. We stand in the midst of major HSS G.T. threading taps Suppliers in India. Technical Specifications : Available from 1/8" to 8" (BSW, BSF, UNC, UNF) Available from 1/8" to 6" (BSP, BSPT, NPS, NPT, NPTF, NPSF) Available from 3 mm to 205 mm (metric threads) in Fine Pitch and Coarse Pitch. Fine Pitch Taps are in set of 2 Pcs and Coarse Pitch Taps are in set of 3 Pcs. Also available in British Standard Conduit and British Standard Brass Whitworth forms

Best Deals from Bathroom Fittings

Thread Forming Tap

100 Per Piece

1 Piece (MOQ)

BSP Taps

Get Price Quote

The BSP Taps are manufactured using the stainless steel. Our team professionals and experts ensure that the transactions done are exactly as per the guidelines. We maintain stern records of all the transactions done to gain complete satisfaction of our clients. We work in close coordination with the team members and packaging professionals; they ensure that the products are packed sternly using the finest quality packaging materials.

THREADING TOOLS TAPS, THREAD TAPS, THREADING TAP

Get Price Quote

IMC Threading taps are especially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or are drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as for bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface which functions like a nut. Machine Tapping Internal Threading Machine is used tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc. Industrial Machinery Corporation will also offer the benefit of customization.

carbon taps

Get Price Quote

In our broad assortment, we are trading and supplying a qualitative array of Carbon Threading Taps. This threaded tap is manufactured by high class material and modern techniques in compliance with set norms. In addition, the offered threaded tap is checked on numerous parameters so as to assure their flawlessness. Our threaded tap is available in bulk quantity within stipulated time frame from us.

Baby Shower Gift Set

Get Price Quote

Hand Taps-U.N.C. Form

Get Price Quote

we are offering Hand Taps-U.N.C. Form.

Wingnut Taps

Get Price Quote

We have carved a niche for ourselves as a credible Manufacturer, Exporter and Supplier of Wingnut Taps. Available in different sizes, the Wingnut Taps are designed with utmost precision using high speed steel ensuring great strength and high durability. They are used for threading holes in the wing nuts. Further, Wingnut Taps are provided to the customers at very budget friendly prices.

Bathroom Fittings

2,400 - 3,000 Per Per pc

HSS Threading Tap

Get Price Quote

We do not have to worry about stock-out situations or meeting bulk requirements, as we have an equipped warehouse facility. It has the latest inventory control and management software and helps us maintain continuous product availability. We provide customized as well as standard packaging of the products. With the assistance of our streamlined packing system, we are able to provide damage-free products to the clients. Features : Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Threading Taps

Get Price Quote

IMC Threading taps are specially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of the rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface that functions like a nut. Machine Tapping The internal Threading Machine is used a tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps are offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads, etc. Industrial Machinery Corporation will also offer the benefit of customization

steel bathtub

Get Price Quote

The company is a reckoned Manufacturer, Exporter, and Supplier of J4 Stainless Steel Bathroom Gratings worldwide. It is used for draining water from the bathroom, thereby maintaining hygiene. Our bathroom grating is a perfect blend of fine finish, and optimum quality. The offered product is manufactured with the help of the supreme quality stainless steel and advanced machinery under the visionary of trained professionals. Our offered gratings are available at very nominal prices.

Thread Hand Taps E-2421

500 Per Pair

20 Pair (MOQ)

We are the main supplier of this product.

Threading Taps

Get Price Quote

Lambretta Auxiliary Fuel Gas Spare Tank On-Off Tap 300ml

10 Per Piece

As Per Order Piece (MOQ)

Air Shower

Get Price Quote

1 Piece (MOQ)

Features Available in various sizes according to users requirement. Highly effective HEPA filtered air having cleanliness level as high as 99.99% with cold DOP and 99.97% with HOT DOP retaining airborne particles of size 0.3 micron. Pre-filter installed before HEPA filter to the extended life of HEPA filter. Advance Microprocessor Control System. High efficiency statically & dynamically balanced motor blower assembly. Filtration Process High velocity air forced through HEPA filters. Filtered air is thrown in the chamber through jet nozzles with a high velocity which in turn disperse particulate matter on all surface. The lower portion of the Air showers suck the contaminated air and allow it to pass to blower supply plenum through pre-filter installed at the base. This process is a continuous process in which air is continuously filtered and recirculated inside the chamber without any exchange with the external environment. Material Of Constructions "MAC" Air Shower made up of CRC sheet duly powder coated OR Stainless Steel SS-304 (as ordered) and is designed with a heavy and rigid structure to provide enhanced life of the Equipment. High Efficiency Motor Blower Assembly Heavy Duty centrifugal motor blower assembly for high-velocity air throw. Compact design energy-efficient motor and blower are balanced to give smooth, quiet and vibration-free operation. Illumination Arrangements Air Shower chambers are provided with high intensity fluorescent light for uniform lighting throughout the chamber. Nozzle Diffusers Corrosion-resistant, high strength, durable with a flawless array of high-velocity nozzles for direct high-velocity air jets within the chamber. Control System The Air Shower system controls the sequential locking and release of the doors, and control the blower. The two doors are interlocked such that two doors cannot be opened at the same time, to prevent pressure losses and cross-contamination. The special interlocking feature of our Air Shower system achieves this by preventing simultaneous access of door by ensuring that when one door of Air Shower interlocking system is open then another door is closed before the opening of the door. Advance Microprocessor controller having Digital LED Display features interlocking system. Both the doors of the Air Shower are interlocked with each other preventing simultaneous access of the door by ensuring that when one door of Air Shower is open then another door is closed. Only one door can be opened at a time to prevent pressure losses and cross-contamination. The controller will show "WAIT" to indicate that the other door is open. The system controls the sequential locking and release of the door and controls the Blower. The interlocking feature of CFL, UV Tube and blower enables automatic ON of CFL and blower on the opening of the door and when the door will be closed UV Tube will be ON for sterilizing the cross-over area. Advanced Microcontroller based system Delay time between door opening is 4 Sec. Inbuilt sensor Magnetic Lock to read door feedback. Door status indication with high-intensity Bar LEDs The status indication "GO, WAIT, DOOR OPEN, CLOSE DOOR" Buzzer output for door kept open more than specified time from 2 min. UV Lamp controlling UV Lamp On for both doors closed UV Lamp OFF for both doors open CF Lamp controlling CF lamp ON when any door is open CF Lamp OFF for both doors Closed

Brass Bib Cock

110 Per Piece

10 Piece (MOQ)

Shower Sliding Set

Get Price Quote

Assembly parts made with genuine stainless SS 304 grade for SDR-301 set. Height adjustable as per acutal site conditions. Complete set of rollers and track. Made up of Genuine SS-304 material.

Sensor Taps

Get Price Quote

Power : Voltage DC 6-V 220V50Hz(AC) Battery : 4x AA Duracell Alkaline Batteries Power Consumption : 0.5 - mw (DC), < 2 W (AC) Detection Zone : 12-18 cm Water Pressure : 0.05 - 0.6 Mpa Water Temperature : 0- 80 C Degree of Protection : IP 56