Cuplock System

66 - 69 Per Kilogram

15 Ton (MOQ)

we are manufacturing and supplying the best quality cuplock system in the market. We offer a great range of cuplock system to our widely spread clients. Our all products are available at really competitive prices. features cost effective durable great strength best quality raw material used

CUP LOCK WELDING SYSTEM

Get Price Quote

Best Deals from Cuplock System

Cuplock Scaffolding Systems

Get Price Quote

Cuplock System

Get Price Quote

The Pipe of Hot Rolled Steel as per BS-1139 Standard. Made from Pipe of 48mm OD, 4mm or 3.2mm and available in lengths of 1mtr to 3mtr.

Cuplock Scaffolding System

Get Price Quote

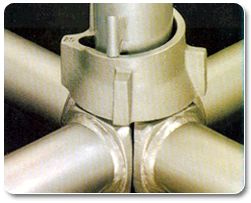

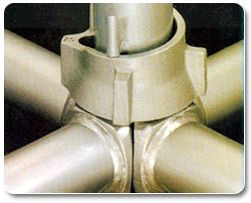

Cuplock Scaffolding System. This type of cuplock systems permits up to four horizontals to be connected in vertical manner in one single action without using bolts and nuts. The locking devices are quite versatile and are formed with two cups, the upper cup is sliding, and the lower cup is welded to the vertical component at pre-located intervals. The upper cup is lowered down and revolved to secure the components in place and then a hemmer blow result in a rigid and positive connection, the forged blade ends of the horizontal components are located into the lower cup.

Cup Lock Type System

Get Price Quote

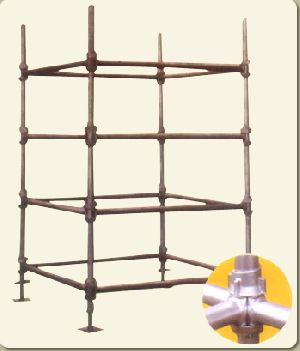

A multipurpose scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship building, offshore construction and industrial maintenance.It provides major savings in erection and dismantling times thus minimizing on-site costs. When not in use, its modular construction ensures minimal space requirements for storage.A unique node point connection allows up to four horizontal members to be connected to a vertical member in one single action - without the use of nuts and bolts or wedges. The locking device is formed by two cups, a fixed lower cup which is welded to the vertical component at pre-located intervals and a sliding upper cup. The forged blade ends of the horizontal components are located into the lower cup, the upper cup is moved down and rotated to secure the components in place and a hammer blow then results in a positive and rigid connection.It is extremely versatile. It can be erected for straight, curved and circular configuration for both access and support, and also for independent and mobile towers. Both vertical and horizontal members are manufactured from 48.3mm overall diameter x 3.2mm gauge high tensile steel to British Standard 4360 Grade 50 (minimum ultimate tensile stress = 534N/mm2).With no loose parts and with corrosion protection by hot dip galvanizing to British Standard 729, minimum thickness of the zinc coating is 85 microns.Conforms to BS1139 Part 5, HD1000, OSHA and Australian New Zealand Standards HIGHLIGHTS Quick fastening of horizontals. Four horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid. Quick erection and dismantling results in time and labour saving. Versatile use in construction, demolition or maintenance projects for any type of structure i.e. straight or curved. Easy erection with no loose components. Lightweight but high loads carrying capacity up to 57 KN per vertical. Low maintenance. Safety with proven track record.

Cup Lock System

Get Price Quote

We are offering cup lock system.

cuplock systems

Get Price Quote

In order to keep pace with the variegated demands of the clients, we are engaged in exporting an excellent gamut of Cuplock Scaffolding System. This type of cuplock systems permits up to four horizontals to be connected in vertical manner in one single action without using bolts and nuts. The locking devices are quite versatile and are formed with two cups, the upper cup is sliding, and the lower cup is welded to the vertical component at pre-located intervals. The upper cup is lowered down and revolved to secure the components in place and then a hemmer blow result in a rigid and positive connection, the forged blade ends of the horizontal components are located into the lower cup.

Cuplock System

Get Price Quote

We manufacture and export a wide range of Cup Lock Scaffoldings. These products are designed to be used with standard scaffold tubes. Our Cup Lock Scaffoldings are of high performance and provide the building industry with completely safe, economical solutions for Scaffolding Design.Following products comes under this categoryTop CupBottom CupLadger Blade

Scaffolding Cuplock System

Get Price Quote

Cup Lock System

Get Price Quote

We are offering Cup Lock System

Cuplock System

Get Price Quote

We are One of the Distinguished Manufacturer and Exporter of Cuplock Systems. Our Cuplock Systems are Perfectly Suited for Forming Rigid Connections Between the Joints and Pipes, Without the Use of Nuts and Bolts. We Offer Durable and Stringent Quality Cuplock Systems to Connect Several Joints for Forming Solidified Platforms and Structures Building & Construction Industries. to Add Further, Our Cuplock System is Highly Resistant to Damage and Corrosion. the System Provided By Us, Can Be Easily Maintained and Re-used.

Cup Lock Type System

Get Price Quote

HIGHLIGHTS Quick fastening of horizontals. Four horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid. Quick erection and dismantling results in time and labour saving. Versatile use in construction, demolition or maintenance projects for any type of structure i.e. straight or curved. Easy erection with no loose components. Lightweight but high loads carrying capacity up to 57 KN per vertical. Low maintenance. Safety with proven track record. A multipurpose scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship building, offshore construction and industrial maintenance.It provides major savings in erection and dismantling times thus minimizing on-site costs. When not in use, its modular construction ensures minimal space requirements for storage.A unique node point connection allows up to four horizontal members to be connected to a vertical member in one single action - without the use of nuts and bolts or wedges. The locking device is formed by two cups, a fixed lower cup which is welded to the vertical component at pre-located intervals and a sliding upper cup. The forged blade ends of the horizontal components are located into the lower cup, the upper cup is moved down and rotated to secure the components in place and a hammer blow then results in a positive and rigid connection.It is extremely versatile. It can be erected for straight, curved and circular configuration for both access and support, and also for independent and mobile towers. Both vertical and horizontal members are manufactured from 48.3mm overall diameter x 3.2mm gauge high tensile steel to British Standard 4360 Grade 50 (minimum ultimate tensile stress = 534N/mm2).With no loose parts and with corrosion protection by hot dip galvanizing to British Standard 729, minimum thickness of the zinc coating is 85 microns.Conforms to BS1139 Part 5, HD1000, OSHA and Australian New Zealand Standards

Cuplock Scaffolding System

Get Price Quote

Eastman Scaffolding is engaged in manufacturing and exporting an extensive gamut of cuplock scaffolding systems to handle different demands of the clients. Our cuplock systems can connect up to four horizontals in a vertical manner without using any bolts or nuts. Our locking system is very versatile in nature, and incorporates two cups in structure.

cuplock systems

Get Price Quote

We are a leading manufacturer & exporter of cuplock systems such as ledger cuplock system, bottom cup pressed, top cup forged, top cup (casted), ledger blade (ledger end), vertical cuplock system and many more items from india.

Cup Lock System

Get Price Quote

Cup Lock System, round hook, ground plate, Steel Clamps

Cuplock Scaffolding System

Get Price Quote

Cuplock Scaffolding System, Scaffolding Materials, Flat Washers

cuplock systems

Get Price Quote

cuplock systems, pressed steel scaffold fittings, form work accessories

Cuplock System

Get Price Quote

Cuplock System, Scaffolding Fittings, Scaffolding, Scaffolding Accessories

Cuplock System

Get Price Quote

Cuplock System, Scaffoldings, Couplers, Channel Nuts, THREADED RODS