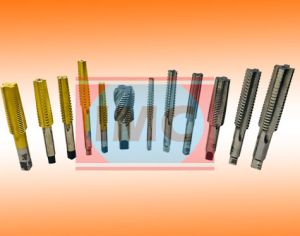

hss gt threading tap

Get Price Quote

General Specification: Thread - TPI or Pitch: 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material: Carbon Steel, HSS Includes: Wooden Case, Taps, Dies Type: Tap & Die Special Taps: Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

HSS Nut Drilling Taps

Get Price Quote

All our payment methods are practical and convenient. A method is agreed upon by us with you at the time of undertaking to ensure no confusion or problem arises later on. Designed and developed using the best quality material, we pack them meticulously so as to ensure hassle free deliveries. Also, we make sure that only premium material is used for packaging. Features : High grade metal Corrosion resistant Dimensionally stable

Best Deals from Faucet

metric taps

Get Price Quote

Sensor Taps

Get Price Quote

Power : Voltage DC 6-V 220V50Hz(AC) Battery : 4x AA Duracell Alkaline Batteries Power Consumption : 0.5 - mw (DC), < 2 W (AC) Detection Zone : 12-18 cm Water Pressure : 0.05 - 0.6 Mpa Water Temperature : 0- 80 C Degree of Protection : IP 56

Lambretta GP Standard Fuel Tap Brass

10 Per Piece

ground thread taps

Get Price Quote

all types of ground thread tap such as hand taps, snt taps , acme taps,pipe thread taps,machine taps etc

HSS Threading Taps

Get Price Quote

We offer superior quality HSS Threading Taps that are commonly used in various industries. To match the different needs of the clients, we provide HSS Ground Thread Taps in various sizes. High durability, excellent performance and low maintenance are some of the salient features of our High Speed Steel Thread Taps. We stand in the midst of major HSS G.T. threading taps Suppliers in India. Technical Specifications : Available from 1/8" to 8" (BSW, BSF, UNC, UNF) Available from 1/8" to 6" (BSP, BSPT, NPS, NPT, NPTF, NPSF) Available from 3 mm to 205 mm (metric threads) in Fine Pitch and Coarse Pitch. Fine Pitch Taps are in set of 2 Pcs and Coarse Pitch Taps are in set of 3 Pcs. Also available in British Standard Conduit and British Standard Brass Whitworth forms

HSS Spiral Pointed Tap

375 Per Piece

25 Piece (MOQ)

Fluted Tap

Get Price Quote

hese standard style taps have straight flutes of a number specified as either standard or optional. Hand taps are for general purpose applications such as production tapping or hand tapping operations. Taper, plug and bottoming styles provide versatility in tough materials, blind and through holes.

Thread Hand Taps E-2421

500 Per Pair

20 Pair (MOQ)

We are the main supplier of this product.

HSS Threading Tap

Get Price Quote

We do not have to worry about stock-out situations or meeting bulk requirements, as we have an equipped warehouse facility. It has the latest inventory control and management software and helps us maintain continuous product availability. We provide customized as well as standard packaging of the products. With the assistance of our streamlined packing system, we are able to provide damage-free products to the clients. Features : Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Brass Bib Cock

110 Per Piece

10 Piece (MOQ)

Threading Taps

Get Price Quote

IMC Threading taps are specially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of the rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface that functions like a nut. Machine Tapping The internal Threading Machine is used a tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps are offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads, etc. Industrial Machinery Corporation will also offer the benefit of customization

Cp Taps

750 - 4,500 Per Per pc

Catering to the needs of the clients, we present cp tap to the clients. The cp tap is procured from reliable vendors and is appreciated for its flawless quality. The cp tap has perfect finish and therefore high on demand.

THREADING TOOLS TAPS, THREAD TAPS, THREADING TAP

Get Price Quote

IMC Threading taps are especially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or are drawn up along the flutes, removing the chips and cutting fluids from the hole. A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability. Threading is divided into two types, internal and external. Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as for bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of rod for the size and pitch of the threads you want to cut. Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing. A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface which functions like a nut. Machine Tapping Internal Threading Machine is used tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated. Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping. The Threading Taps offered by Industrial Machinery Corporation. Different types of Threading Taps can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc. Industrial Machinery Corporation will also offer the benefit of customization.

HSS Straight Fluted Taps

Get Price Quote

Threading Taps

Get Price Quote

Hand Taps

Get Price Quote

We are a well-known Manufacturer, Exporter and Supplier of the best quality Hand Taps. Hand Taps, offered by us, have carbon steel finish for small job works. The Hand Taps are completely hardened, tempered and torque tested products, as per DIN and other international standards. Avail Hand Taps from us at very reasonable prices. Packaging Material : PP bags Blister Blister cords Plastic rack Corrugated cartons Minimum Order Quantity : 1 X 20 feet container

Taps

Get Price Quote

Short Machine Taps Spiral Point Taps Nib Taps Long Nut Taps Long Machine Taps Fluetless Taps Spiral Fluted Taps Pully Taps Range: Taps are available in the following Range: 1 mm to 150 mm. 1/16" to 6" We also manufacture Taps as per customers size & specifications. Thread Foams: BSW / BSF / UNC / UNF / METRIC / UNEF / UNS / BA / BSP / BSPT / BSCY / CEI / WF / ME / BS CON / NPT / NPTF / NPSM / NPSL / NPSI / NGT / NH / PG / ACME / SQUARE / TRAPEZOIDAL / BUTTRESS / KNUCKLE / HELICOIL / TAPER THREAD 3:25, 1:8, 1:16, Surface Treatment: Blued / Nitrated / Tin Coated. Material: Available in M2, M35 as well as in special steel as per customers specifications. Tolerance: 4H, 6H, 7H. Zone 2, Zone 3, Zone 4. Class 1, Class 2, Class 3. GH 1 to GH 7. Under sizes.

threading tap

Get Price Quote

Short Nut Tap

250 Per Piece

HSS Threading Taps

Get Price Quote

We have ultra-modern packaging systems available to keep the products safe from physical factors that may damage the product to some extent. Thus, we only use qualitative packaging material. One can stay assured for high quality of the offered lot as we design and develop it using the best in line raw material and modern work methods. In addition to this, we make sure that the material is sourced from the trusted places only. Features : Thread - TPI or Pitch : 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material : Carbon Steel, HSS Includes : Wooden Case, Taps, Dies Type : Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. theoretical knowledge and practical experience are intrinsic in this process. size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Carbon Threading Taps

Get Price Quote

We are offering hss & carbon threading taps.

Threading Taps

Get Price Quote

Made from selected high speed steel, our Threading Taps feature tools that are properly tempered and stress relieved. The Tap Blanks of Threading Taps are heat treated In-house with the help of high accuracy temperature controlling system so that optimum hardness along required toughness and wear resistance is imparted to tools. We are a remarkable entity engaged in offering superior quality assortment of Threading Tap. Our skilled professionals manufacture the entire range using world class raw material and sophisticated technology, as per international quality standards. To meet the variegated demands of the clients, we offer these products in different related specifications. In addition to this, we offer our products at a reasonable price range.

PG Thread Taps

Get Price Quote

the pg thread series is designed specifically for steel conduit because of the thin wall cross section of the steel conduit. The thin wall thickness requires a shorter profile thread that will not break through the outside diameter of the steel conduit during the machining process. The 80° included angle of the pg thread form gives a shorter profile than the more common 60° included angle found in the unified national thread series and the metric thread series. pg thread taps are made as per din 40430

HSS Threading Tap

Get Price Quote

Thread - TPI or Pitch: 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material: Carbon Steel, HSS Includes: Wooden Case, Taps, Dies Type: Tap & DieSpecial Taps: Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process.Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

Thread Hand Taps

Get Price Quote

Mild Steel

H.S.S Ground Thread Taps

Get Price Quote

Straight Flute : Short Machine & Hand Taps, Long Shank Machine Taps, Long Shank Nut Taps & Nib Taps.Spiral FluteSpiral Point Taps :Thread Form : BSW, BSF, UNF, UNC, BA, BSP, NPS, BSPT, NPT, NPTF, NGT, BSCY, ACME, Interrupted & Spl. Threads.Standard Specification : IS: 6175 1977 PART I II & III, BS:949, ANSI:B. 94. 9, DIN 352-371-376Product Range : 18" to 4" (M 3 to M 100) and Spl. on order

nut taps

150 Per Piece

HSS Threading Taps

Get Price Quote

Our organization assures distribution of wholesale as well as retail consignments of the goods as per the jointly decided period. We have our own storage unit wherein we keep a large stock for meeting urgent and massive requirements of the clients. Laced with modern amenities, this unit keeps the lot free from the damaging factors. Features : Thread - TPI or Pitch - 1/8 in - 27 NPT, 1/4 in - 18 NPT, 3/8 in - 18 NPT, 1/2 in - 14 NPT, 3/4 in - 14 NPT, 1 in - 11 1/2 NPT Material - Carbon Steel, HSS Includes - Wooden Case, Taps, Dies Type - Tap & Die Special Taps : Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding. There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.