slides Forging Hammer Pillars

Cast steel columns duly-annealed and machined are very stiff and robust in construction to ensure longer stability. These are positioned by a large spigot on underside of each foot which fits into a machined recess in the anvil block. The columns are locked with the help of tapered wedges of alloy steel to ensure firm alignment of columns which helps in accurate guiding of tup (made out of EN-9 cast steel.) The clearance between the tup and guide ways attached to columns is maintained with the help of tapered wedge which brings the columns inward and drawback bolt provided pushes the columns outwards. Synthetic rubber mat is provided on anvil block on which the columns rest. It dampens the induced shock vibrations which increase the life of the tup and also ensures smooth working of the machine for longer period.

...more

Screw Press

This Screw Press is also known as Forging Presses or Screw Presses. These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging.Vincent Presses are screw presses with friction drive on which the forging blow takes place in an upward direction, that is, from bottom towards top.

...more

Power Press H Frame

NKH is one of the established Manufacturer, Exporter and Supplier of H Frame Power Press Machine. We manufacture H Frame Press Machine in different series that boast assorted features. Our H Frame Press Machine series is preferred for its flawless performance, sturdy construction, and high productivity rate. These machines are easy to maintain and easy to operate. We are manufacturer of all type of power presses i.e. Pillar type (Marshal type), inclinable type (American Type) and Heavy Duty Crankless Presses upto 1000 tons. We manufacture these presses out of good cast iron as well as fabricate them depending upon the choice of our clients. Our presses are ideal for Cutting, Blanking, Piercing, Drawing and Trimming purposes etc. This Power Press is also known as Training Press or Power Press Features Capacity Ranging from 20 to 500 tons. The frame is of most rigid construction of one piece steel welded construction of fusion welding quality and fully stress relieved. All bushes of nickel phosphors bronze. Provided with foot operated rolling key clutch. Supplied with adjustable strokes.Stroke may be changed in thirty seconds. Centralized lubrication is provided. This H Frame Power Press is also known as: Training Power Press Power Press Pillar Type Power Press Marshal Type Power Press inclinable Type Power Press American Type Heavy Duty Crankless Presses

...more

mechanical power press machines

NKH is a leading name in manufacturing mechanical power press machines and tools and commands a name for high quality production and perfect performance. Solid steel with suitable cross ribbing is used in manufacturing the C-Frame Power Presses. Rolling key type of clutch is employed in the C-Frame that offers incessant strokes for mass production. Special alloy steel is used for manufacturing crankshaft and fitted in with gunmetal bushes for smooth performance and extended durability. To acquire enormously high precision press operation, table and ram are impeccably aligned to each other. Features Capacity Ranging from 5 to 315 Tons. This C-Type press features one piece frame of rolled steel plates, carefully proportioned and Mig welded for maximum strength and rigidity. Crankshaft from high carbon steel. Crank pins are extra large to minimize deflection and to provide wide bearing areas. The press is equipped with Rolling key clutch with repeated and non-repeated safety device.

...more

Pneumatic Shearing Machine

Our Billet Shearing machines ensure perfect cuts both for square ness and for cleanness of the shearing surface. “NKH” technology allows a precise adjustment way alloyed & mild steels, aluminum, brass etc. The beauty of our shearing machines are to incorporate maximum possible facilities to their users without incurring exorbitant investment. The frames of our machines are rigged & construction and high quality materials are used for their manufacturing. Due to our excellent workmanship and finish of our machines bears pleasant outlook.

...more

Pneumatic Press Machine

NKH is one of the established Manufacturer, Exporter and Supplier of H Frame Pneumatic Press. We manufacture H Frame Pneumatic Press Machine in different series that boast assorted features. Our H Frame Press Machine series is preferred for its flawless performance, sturdy construction, and high productivity rate. These machines are easy to maintain and easy to operate. We are manufacturer of all type of power presses i.e. Pillar type (Marshal type), inclinable type (American Type) and Heavy Duty Crankless Presses upto 1000 tons with pneumatic Clutch and Die Cusion. We manufacture these presses out of good cast iron as well as fabricate them depending upon the choice of our clients. Our presses are ideal for Cutting, Blanking, Piercing, Drawing and Trimming purposes etc.

...more

Pneumatic Press H Frame

NKH is one of the established Manufacturer, Exporter and Supplier of H Frame Pneumatic Press. We manufacture H Frame Pneumatic Press Machine in different series that boast assorted features. Our H Frame Press Machine series is preferred for its flawless performance, sturdy construction, and high productivity rate. These machines are easy to maintain and easy to operate. We are manufacturer of all type of power presses i.e. Pillar type (Marshal type), inclinable type (American Type) and Heavy Duty Crankless Presses upto 1000 tons with pneumatic Clutch and Die Cusion. We manufacture these presses out of good cast iron as well as fabricate them depending upon the choice of our clients. Our presses are ideal for Cutting, Blanking, Piercing, Drawing and Trimming purposes etc. Features Capacity Ranging from 20 to 500 tons. The frame is of most rigid construction of one piece steel welded construction of fusion welding quality and fully stress relieved. All bushes of nickel phosphors bronze. Provided with foot operated rolling key clutch. Supplied with adjustable strokes.Stroke may be changed in thirty seconds. Centralized lubrication is provided.

...more

Pneumatic Press C Frame machines

Our Power presses covers the whole range of pressing and forming operations. The press frame is made in one single piece weld body and is shaped like a ‘C’. These pneumatic press C frame are mostly employed for blanking, piercing, stamping, bending trimming and clinching operations. Power Presses what we are manufacture is of steel fabricated frame, using best raw materials that are tested for long life, efficiency and reliability. We also do stress relieving to all fabricated frames and follows standard practice of seasoning casting. These presses are provided with pedal operated rolling key clutch. We also manufacture customized Pneumatic “C” Frame Power Presses as per client requirements. Features Capacity Ranging from 5 to 315 Tons. This C-Type press features one piece frame of rolled steel plates, carefully proportioned and Mig welded for maximum strength and rigidity. Crankshaft from high carbon steel. Crank pins are extra large to minimize deflection and to provide wide bearing areas. The press is equipped with Rolling key clutch with repeated and non-repeated safety device.

...more

Pillar Type Power Press

We manufacture H Frame Press Machine in different series that boast assorted features. Our H Frame Press Machine series is preferred for its flawless performance, sturdy construction, and high productivity rate. These machines are easy to maintain and easy to operate.We are manufacturer of all type of power presses i.e. Pillar type (Marshal type), inclinable type (American Type) and Heavy Duty Crankless Presses upto 1000 tons. We manufacture these presses out of good cast iron as well as fabricate them depending upon the choice of our clients. Our presses are ideal for Cutting, Blanking, Piercing, Drawing and Trimming purposes etc.

...more

Lifting Jacks

Inclinable Power Press

NKH is one of the established Manufacturer, Exporter and Supplier of H Frame Power Press Machine. We manufacture H Frame Press Machine in different series that boast assorted features. Our H Frame Press Machine series is preferred for its flawless performance, sturdy construction, and high productivity rate. These machines are easy to maintain and easy to operate. We are manufacturer of all type of power presses i.e. Pillar type (Marshal type), inclinable type (American Type) and Heavy Duty Crankless Presses upto 1000 tons. We manufacture these presses out of good cast iron as well as fabricate them depending upon the choice of our clients. Our presses are ideal for Cutting, Blanking, Piercing, Drawing and Trimming purposes etc. This Power Press is also known as Training Press or Power Press

...more

Head Assembly

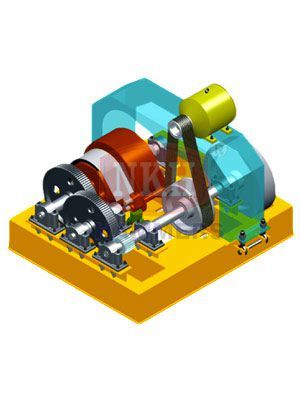

Heavy duty head assembly fabricated from rolled steel sections is mounted on top of the columns. The drive is through v-belts from high torque A.C. Electric motor via flywheel and reduction gears to the lifter-shaft. Friction lifting system is fitted to lifter shaft which runs on double ball bearings and one central phosphorus bronze bearing which also serves as support to lifter shaft. The friction lifter consists of constantly rotating drum and break lined steel band. This band is anchored at one end to stud in lifter drum and other end is carried by camshaft running through lifter drum which actuated by lever. The lever is operated with the help of pulling cord tied to lever at one end goes to operating point by passing through capstan bush attached to lifter shaft. When the cord is pulling it tightens on to the rotating capstan bush which operate the lever resulting in tightening of brake around the brake drum with the help of cam shaft. At this stage lifter drum is rotated and to tup is lifted with the help of nylon belt provided. On release of cord the spring loaded arrangement help free fall of tup by disengaging friction band immediately from the friction drum. The spring loaded buffer work as a stopper for lifting drum is its rest position. Positive water cooling arrangement is provided to the friction drum to prevent excessive heating.

...more

friction screw presses

This Screw Press is also known as Forging Presses or Screw Presses. These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging. Vincent Presses are screw presses with friction drive on which the forging blow takes place in an upward direction, that is, from bottom towards top. On machines employing the Vincent principle, the screw nut is positioned in the top cross head of a frame type ram. Thus Ram is moved upwards in axial direction by rotation of longitudinally fixed screw.

...more

Friction Screw Press VFP (Up Stroke)

This Screw Press is also known as Forging Presses or Screw Presses. These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging. Features Vincent Presses are screw presses with friction drive on which the forging blow takes place in an upward direction, that is, from bottom towards top. On machines employing the Vincent principle, the screw nut is positioned in the top cross head of a frame type ram. Thus Ram is moved upwards in axial direction by rotation of longitudinally fixed screw. The bottom die of the forging tools is secured to the lower crosshead of the Ram while the top die is fitted to a fixed bridge which is the part of the machine frame. The forging forces do not act on the machine frame but are sustained by the Ram. Ejector is provided at the lower part of the Ram.

...more

Friction Screw Press VFP (Down Stroke)

This Screw Press is also known as Forging Presses or Screw Presses. These Friction Screw presses are preferred for hot forming (Forgings) and cold coining, Stamping, embossing, Sizing nonferrous metals. Features The press body is of steel welded construction, one piece box type design. The screw is made of high quality alloy steel and is heat treated to give hardness and elasticity. The connected flywheel accelerates at the start of working stroke and is braked to a stand still by the actual forming process. Forging accuracy is greater. The forging forces do not act on the machine frame but are sustained by the Ram. Forging is possible in closed die as a screw can not jam under load.

...more

Friction Drop Hammer

NKH Self Contained Friction Drop Hammer is being manufactured in different capacities in India. NKH Friction Hammers have been designed and developed with Indian know-how and materials. This Forging Hammer is also known as Gravity Drop Hammers. Prospective customers are welcome to conduct trials and inspect our range of NKH Hammers at our works in Ludhiana.

...more

forging screw press

This Screw Press is also known as Forging Presses or Screw Presses. These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging.Vincent Presses are screw presses with friction drive on which the forging blow takes place in an upward direction, that is, from bottom towards top. On machines employing the Vincent principle, the screw nut is positioned in the top cross head of a frame type ram. Thus Ram is moved upwards in axial direction by rotation of longitudinally fixed screw.

...more

Forging Hammer

This Forging Hammer is also known as Gravity Drop Hammers. Prospective customers are welcome to conduct trials and inspect our range Capacity Ranging from 500 Kgs to 10000 Kgs (10 Tonnes).Both Skilled and Non-skilled Labour can operate it easily.Versatile in manufacturing forged components.

...more

Drop Hammer

NKH Self Contained Friction Drop Hammer is being manufactured in different capacities in India. NKH Friction Hammers have been designed and developed with Indian know-how and materials. This Forging Hammer is also known as Gravity Drop Hammers. Prospective customers are welcome to conduct trials and inspect our range of NKH Hammers at our works in Ludhiana.

...more

drop forging hammer

NKH Self Contained Friction Drop Hammer is being manufactured in different capacities in India. NKH Friction Hammers have been designed and developed with Indian know-how and materials. This Forging Hammer is also known as Gravity Drop Hammers. Prospective customers are welcome to conduct trials and inspect our range of NKH Hammers at our works in Ludhiana.

...more

Cross Shaft Press

More accurate – NKH Cross Shaft Power Presses that raise standard’s of precision & rigidity. Single Point Suspension Non-Inclinable Single Action Press having steel plate fabricated construction, duly stress relieved with 6 Point gibbing of slide, fitted with pneumatically operated combined single disc. friction clutch & brake. Features Reduced Noise & Vibrations Minimal Frame Gapping, Low Angular Deflection < 1.5 minutes High Rigidity Frame & Bolster High Precision Forming for Longer Die Life Hi-Torque Pneumatically Operated Single Disc Combined Clutch & Brake Unit Gear Transmission Runs in Oil Bath Wide Slide & Bolster Area

...more

Billet Shearing Machine

Our Billet Shearing machines ensure perfect cuts both for square ness and for cleanness of the shearing surface. “NKH” technology allows a precise adjustment way alloyed & mild steels, aluminum, brass etc. The beauty of our shearing machines are to incorporate maximum possible facilities to their users without incurring exorbitant investment. The frames of our machines are rigged & construction and high quality materials are used for their manufacturing. Due to our excellent workmanship and finish of our machines bears pleasant outlook. Features: These machines are manufactured to cut various sizes of Blooms and Slabs. The capacity of these machines varies from 50mm to 200mm. Six number of gears are provided to facilitate operations with small power. The body is made from M.S. (plates). Cutting of Stainless Steel Billet 50mm to 200mm Plate thickness ½” to 2”, width 8”

...more

Belt Drop Hammer

NKH Self Contained Friction Drop Hammer is being manufactured in different capacities in India. NKH Friction Hammers have been designed and developed with Indian know-how and materials. This Forging Hammer is also known as Gravity Drop Hammers. Prospective customers are welcome to conduct trials and inspect our range of NKH Hammers at our works in Ludhiana. Forging Hammer Features Capacity Ranging from 500 Kgs to 10000 Kgs (10 Tonnes). Both Skilled and Non-skilled Labour can operate it easily. Versatile in manufacturing forged components. Spare Parts are readily available. Minimum Electricity Consumption. Easy Maintenance. This Drop Forging Hammer is also known as: Belt Drop Hammer Friction Drop Hammer Gravity Drop Hammer

...more

Anvil Block

It is made of grey cast iron weighting approx. 20 times of nominal capacity of the ram. It is machined on both top & bottom faces to hold die holder firmly and maintain position of the columns. The die holder fixed in the anvil block is forging from high grade alloy steel all over hardened and it is positioned properly with help of alloy steel tapered wedge.

...moreBe first to Rate

Rate ThisOpening Hours