Drilling Cum Milling Machine

Get Price Quote

We are one of the leading Manufacture, and distributors of machine tools in India. We mainly deal in Workshop Machineries, Sheet Metal Machines, Wood Working Machines, Automobile & Garage Machines, Plastic & Printing Machines, Paper Cutting Machine, Welding Machines, Food Processing Machines as well as Special Purpose Machines.

Pillar Drilling Machine

Get Price Quote

Our Pillar Drilling Machine can be used perfectly for drilling holes in different materials. We trade in the 13 MM Bench Type Pillar Drill which comes loaded with features that can be customized as per requirement. Our Pillar Drilling Machine can efficiently drill an extensive variety of materials. Special Features : Sturdy construction Low maintenance Corrosion resistant Affordable pricing Ideal for drilling : Metal sheets Glass Concrete Plastic Wood Rocks Heavy duty machines

Best Deals from Heavy Drilling Machine

radial drills machine

Get Price Quote

We are into Manufacturing and Exporting of Radial Drills Machine that is fabricated as per set industrial standards. This Radial Drills Machine is intended for massive & heaving duty operation and finds application in various industries. These machines can be accessed at market leading prices. Salient Features Rugged constructionUser friendly operationHigh tensile strengthLonger service lifeLow maintenance cost Comes with Coolant systemWork lightChip guardT-Slotted work tableTool boxTest chart and high endurance certificateInstruction and maintenance manual Technical Specifications Item Model JP-R40 JP-R50 JP-R65 JP-R75 JP-R100 JP-R125 JP-R150 Max. Drilling Diameter mm 40 50 65 75 100 125 150 Distance between spindle axis column (min-max) mm 320-320 350-1100 350-1600 450-2000 500-2500 570-3150 600-4000 Distance between spindle nose and working surface of base plate mm 90-350 320-1220 320-1220 400-1600 550-2000 750-2000 750-2500 Vertical travel of radial arm mm 500 550 580 800 1000 1250 1250 Travel of spindle head along arm mm 500 900 1250 1550 2000 2580 3400 Column diameter mm 200 310 350 450 550 700 800 Spindle diameter mm 60 75 79 85 104 112 142 Spindle travel mm 240 225 315 400 450 500 560 Spindle taper Morse No. 4 Morse No. 5 Morse No. 5 Morse No. 5 Morse No. 6 Morse No. 6 Metric 80 Range of spindle speed (step) RPM 75-1220 (6) 40-1220 (9) 25-2000 (16) 20-1600 (16) 16-1250 (16) 8-1000 (22) 63-800 (22) Range of spindle feed (step) mm/r 0.10-0.25 (3) 0.05-0.125 (3) 0.04-3.20 (16) 0.04-3.20 (16) 0.04-3.20 (16) 0.06-3.20 (16) 0.06-3.20 (16) Size of worktable 400x350 400x400 500x630 630x800 800x1000 800-1250 800-1250 Main motor/arm elevation kw 1.5/.5 2.2/1.5 03/01/05 5.5/1.5 7.5/2.2 15/3 18.5/3 Net weight of machine kg 1800 2500 3500 7000 11000 20000 28500

Itco Drilling machine

Get Price Quote

5 Piece (MOQ)

Vertical & Horizontal Drill Machine

150,000 Per Piece

We pali machine tools manufacture all types of multi spindle drill machines.hydrulic and penumatic . Automatic and fully automatic .

CENTRE FACING DOUBLE DRILLING MACHINE

Get Price Quote

We, NAVTECH INDIA, most commonly known as NTS, are the manufacturers of versatile and high precision auto Production Lathe ,Special Purpose machines and many of its kinds. NTS's plant is equipped with design infrastructure, modern manufacturing equipment and systems for quality control through all stages of manufacture.

Scaffolding Inner Prop Drilling Machine

Get Price Quote

Keeping in mind the growing requirements of Scaffolding Industries, we are engaged in offering sophisticated range of Multi Spindles Drill Machines for Inner Prop. These machines are widely used for Drilling of the Components Specially in Inner Prop. Available in different capacities, these are widely appreciated by clients for high performance and low maintenance.This Machine is specially design to boost the Production at lowest labour cost with high level of accuracy in Inner Prop (Scaffolding).

Geared Radial Drilling Machine

Get Price Quote

Our clients can avail from us a wide range of All Geared Radial Drilling Machine. These are designed as per the industry standards and are offered in various technical specifications to our clients.

Pellet Die Cnc Drilling Machine

650,000 Per Piece

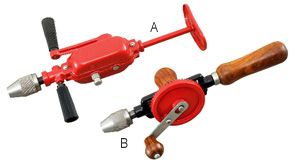

Drill Machine

Get Price Quote

Drill Machine (A) Breast Drill(Double Speed with 3 Jaw Chuck)(B) Hand DrillWith 3 Jaw ChuckAvailable Wooden, Plastic Handle

Drilling Machines

Get Price Quote

Drilling Machines work to create deep holes easier in harder objects such as wood, fiberglass, ceramics, plastic, porcelain tile. These drilling machines bore into the work pieces to produce small precise parts of solid materials in regard to needed depth and diameter of holes. Furthermore, a rotary-percussion drill works to chip away hard materials like masonry (brick or stone) with its action. Machine drills are responsible for cutting materials and available in two most common types as bench and pillar drills. Pillar drill or bench drill are practical choices to get high accuracy in terms of holes that consumes less energy. The machines costs vary with its production level so buyers choose drilling machines that best fits their needs. Drilling holes is the most common task for woodworking and engineering workshops that allows woodworkers to perfectly drill angled holes into wood pieces. So for this, quality parameters are checked on accuracy, construction, performance, durability, power consumption for proper working of machines. There are different technical grades and specifications available with machine dock that guarantee consistent functionality, operational life, high tolerance capacity and supreme work-ability at affordable rates to make the process easier and efficient with speed.

multi head drilling machine

Get Price Quote

Machine Particulars No. of Size Two Head 4 Drilling Two Head 2 Drilling Stroke of Slide In mm 150 150 Minimum Centre distance from Top of Cross Slide In mm 165 140 Max. Drill Size In mm 3 to 15 3 to 25 Max. Length of Drill In mm 100 100 Hydraulic Working In Kg cm² 12 15 Pump Output In Lt Min. 6 8 Power Pack In H.P. 2 2

AUTOMATIC DRILLING MACHINE

Get Price Quote

zero till drill machine

Get Price Quote

Conventional sowing of wheat crop after Paddy harvesting is quite difficult & costly affair. Because it takes about 5-7 tilling operations before a seedbed is prepared. This delays the crop sowing, which consequently affects the crop yield and eats into the margins. Now this problem can be tackled with "National Zero Till Ferti-Seed Drill" developed by G.B. Pant University of Agriculture & Technology, Pant Nagar. This machine enables us to sow directly after paddy harvest without prior seedbed preparation. This saves the diesel, tractor's working time, labour and most important it gives higher yield.

Pillar Drilling Machine

Get Price Quote

Drill Machine

Get Price Quote

Drill Machine, Threading Machine, All Gear Milling Machine

Radial Drilling Machines

Get Price Quote

Radial Drilling Machines, Lathe Machines, Agricultural Hand Tools

Hydraulic Drilling Machine

Get Price Quote

Hydraulic Drilling Machine, Hydraulic Power Packs, Hydraulic Presses

Radial Drilling Machine

Get Price Quote

Radial Drilling Machine, Milling Machine, Horizontal Boring Machine

Hydraulic Multi Spindle Drilling Machine

Get Price Quote

Hydraulic Multi Spindle Drilling Machine, SPM Pipe Bending Machine